LifeTrac Manufacturing Instructions: Difference between revisions

No edit summary |

m (Text replace - "openfarmtech.org/weblog" to "blog.opensourceecology.org") |

||

| (3 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

=Introduction= | =Introduction= | ||

As of December 27, 2011 - we are currently working on LifeTrac Prototype IV - which features bent loader arms and [[Quick Connect Wheels]]. The new loader is [[File:loaderbent.pdf]]. When the new wheel motors and loader arms are tested, they will be added to the official CAD. For now, we recommend replication of only the frame, unless one is a dedicated developer. | As of December 27, 2011 - we are currently working on LifeTrac Prototype IV - which features bent loader arms and [[Quick Connect Wheels]]. The new loader is [[File:loaderbent.pdf]]. When the new wheel motors and loader arms are tested, they will be added to the official CAD. For now, we recommend replication of only the frame, unless one is a dedicated developer. | ||

The difficulty with the motor shafts breaking involved the mislabeling of the hydraulic wheel motors by surplus center, where we discovered that the motors were simply not rated for the pressure that we used. The tractor can be built as is by replacing the wheel motors with stronger [[15,000 Inch Pound Motor]]s. The straight loader arms have poor weight balance, so we recommend building the bent loader arms of [[File:loaderbent.pdf]] instead. These can be built by leaving the arm pivot exactly as it is, with a cut in the arms followed by welding on gussets. These arms will be optimized in the future. The quick connect wheels appear to be a robust solution. | The difficulty with the motor shafts breaking involved the mislabeling of the hydraulic wheel motors by surplus center, where we discovered that the motors were simply not rated for the pressure that we used. The tractor can be built as is by replacing the wheel motors with stronger [[15,000 Inch Pound Motor]]s. The straight loader arms have poor weight balance, so we recommend building the bent loader arms of [[File:loaderbent.pdf]] instead. These can be built by leaving the arm pivot exactly as it is, with a cut in the arms followed by welding on gussets. These arms will be optimized in the future. The quick connect wheels appear to be a robust solution. | ||

= | =Documents= | ||

* Computer Aided Manufacturing (CAM) Files are available for the various mounting plates. See [[Tractor CAM files – wheel, bearing, and motor mount plates]]. | |||

=Parts Manufacture= | |||

==Frame== | |||

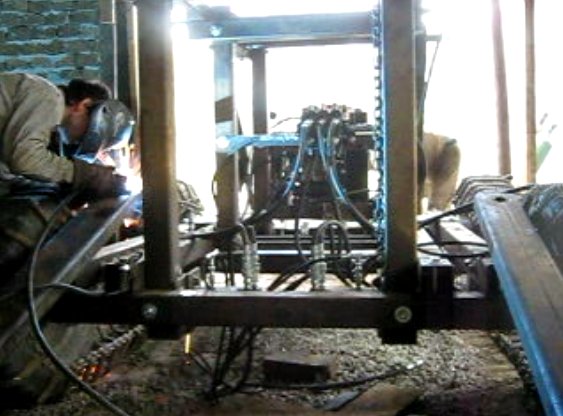

Then, [http://blog.opensourceecology.org/2010/07/lifetrac-ii-frame-2/ build the frame]. | |||

Frame Construction Video Script [[http://opensourceecology.org/wiki/LifeTrac_II_Build/Frame_Construction_Video_Script]] | |||

<html> | <html> | ||

<embed src="http://blip.tv/play/AYHt4kwC" type="application/x-shockwave-flash" width="480" height="300" allowscriptaccess="always" allowfullscreen="true"></embed> | <embed src="http://blip.tv/play/AYHt4kwC" type="application/x-shockwave-flash" width="480" height="300" allowscriptaccess="always" allowfullscreen="true"></embed> | ||

| Line 28: | Line 23: | ||

</html> | </html> | ||

=Wheels= | ==Wheels== | ||

<html> | <html> | ||

<iframe src="https://player.vimeo.com/video/30152906?title=0&byline=0&portrait=0" width="400" height="225" frameborder="0" webkitAllowFullScreen allowFullScreen></iframe> | <iframe src="https://player.vimeo.com/video/30152906?title=0&byline=0&portrait=0" width="400" height="225" frameborder="0" webkitAllowFullScreen allowFullScreen></iframe> | ||

</html> | </html> | ||

Wheel Assembly Video Script [[http://opensourceecology.org/wiki/Life_Track_II_Build/Wheel_Mount_Construction_Video_Script]] | Wheel Assembly Video Script [[http://opensourceecology.org/wiki/Life_Track_II_Build/Wheel_Mount_Construction_Video_Script]] | ||

Then, [http:// | Then, [http://blog.opensourceecology.org/2010/08/lifetrac-ii-update/ prepare all the wheel mounting materials.] | ||

<html> | <html> | ||

| Line 47: | Line 43: | ||

</html> | </html> | ||

Then, go for the [http:// | Then, go for the [http://blog.opensourceecology.org/2010/08/lifetrac-prototype-ii-test-drive/ first test drive.] | ||

<html> | <html> | ||

| Line 53: | Line 49: | ||

</html> | </html> | ||

=Wheel Tracks= | ==Wheel Tracks== | ||

<html> | <html> | ||

<iframe src="https://player.vimeo.com/video/30354026?title=0&byline=0&portrait=0" width="400" height="225" frameborder="0" webkitAllowFullScreen allowFullScreen></iframe> | <iframe src="https://player.vimeo.com/video/30354026?title=0&byline=0&portrait=0" width="400" height="225" frameborder="0" webkitAllowFullScreen allowFullScreen></iframe> | ||

</html> | </html> | ||

Wheel Tracks Construction video script [[http://opensourceecology.org/wiki/LifeTrac_II_Build/Wheel_Tracks_Construction_Video_Script]] | Wheel Tracks Construction video script [[http://opensourceecology.org/wiki/LifeTrac_II_Build/Wheel_Tracks_Construction_Video_Script]] | ||

Then, [[http:// | Then, [[http://blog.opensourceecology.org/2010/09/extreme-traction/ build the wheel tracks.]] | ||

<html> | <html> | ||

| Line 65: | Line 62: | ||

</html> | </html> | ||

=LifeTrac Hydraulics= | ==LifeTrac Hydraulics== | ||

See [http://blog.opensourceecology.org/2011/10/lifetrac-valves-instructional/ blog | See [http://blog.opensourceecology.org/2011/10/lifetrac-valves-instructional/ blog spot] | ||

| Line 73: | Line 70: | ||

</html> | </html> | ||

=Loader Arms= | ==Loader Arms== | ||

<html> | <html> | ||

<script type="text/javascript" src="http://static.ifixit.net/static/embed/make-embed.js?id=1051"></script> <p><a href="http://makeprojects.com/Project/GVCS-LifeTrac-Loader-Arms/1051/1">GVCS - LifeTrac - Loader Arms</a></p> | <script type="text/javascript" src="http://static.ifixit.net/static/embed/make-embed.js?id=1051"></script> <p><a href="http://makeprojects.com/Project/GVCS-LifeTrac-Loader-Arms/1051/1">GVCS - LifeTrac - Loader Arms</a></p> | ||

| Line 82: | Line 79: | ||

1. Prepare loader arms. | 1. Prepare loader arms. | ||

[[Image:LTfab1.jpg]] | [[Image:LTfab1.jpg]] | ||

2. Mark loader attach plates for hole locations. | 2. Mark loader attach plates for hole locations. | ||

[[Image:LTfab2.jpg]] | [[Image:LTfab2.jpg]] | ||

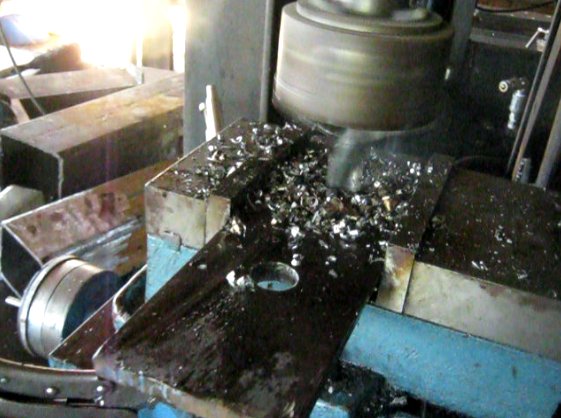

3. Punch or drill mount plate holes. | 3. Punch or drill mount plate holes. | ||

[[Image:LTfab3.jpg]] | [[Image:LTfab3.jpg]] | ||

4. Drill holes in loader arms. | 4. Drill holes in loader arms. | ||

[[Image:LTfab4.jpg]] | [[Image:LTfab4.jpg]] | ||

5. Torch out arm mounts | 5. Torch out arm mounts | ||

[[Image:LTfab5.jpg]] | [[Image:LTfab5.jpg]] | ||

6. Grind arm ends. | 6. Grind arm ends. | ||

[[Image:LTfab6.jpg]] | [[Image:LTfab6.jpg]] | ||

7. Drill or punch 1" holes for cylinder mount bottoms. | 7. Drill or punch 1" holes for cylinder mount bottoms. | ||

[[Image:LTfab7.jpg]] | [[Image:LTfab7.jpg]] | ||

8. Cut pins to size. | 8. Cut pins to size. | ||

[[Image:LTfab8.jpg]] | [[Image:LTfab8.jpg]] | ||

9. Prepare bottom mount plates for loader arms. | 9. Prepare bottom mount plates for loader arms. | ||

[[Image:LTfab9.jpg]] | [[Image:LTfab9.jpg]] | ||

10.Torch out 2" inserts. | 10.Torch out 2" inserts. | ||

[[Image:LTfab10.jpg]] | [[Image:LTfab10.jpg]] | ||

11. Mark arm locations on frame. | 11. Mark arm locations on frame. | ||

[[Image:LTfab11.jpg]] | [[Image:LTfab11.jpg]] | ||

12. Grind 2" inserts. | 12. Grind 2" inserts. | ||

[[Image:LTfab12.jpg]] | [[Image:LTfab12.jpg]] | ||

13. Drill 1" hole in inserts. | 13. Drill 1" hole in inserts. | ||

[[Image:LTfab13.jpg]] | [[Image:LTfab13.jpg]] | ||

14. Torch out holes in frame for loader arms. | 14. Torch out holes in frame for loader arms. | ||

[[Image:LTfab14.jpg]] | [[Image:LTfab14.jpg]] | ||

15. Smooth out holes for loader arms. | 15. Smooth out holes for loader arms. | ||

[[Image:LTfab15.jpg]] | [[Image:LTfab15.jpg]] | ||

17. Fit shafts and DOM bushing for laoder arms. | 17. Fit shafts and DOM bushing for laoder arms. | ||

[[Image:LTfab17.jpg]] | [[Image:LTfab17.jpg]] | ||

18. Finish inserts. | 18. Finish inserts. | ||

[[Image:LTfab18.jpg]] | [[Image:LTfab18.jpg]] | ||

19. Drill rear loader arms. | 19. Drill rear loader arms. | ||

[[Image:LTfab19.jpg]] | [[Image:LTfab19.jpg]] | ||

20. Mark loader arms for insert plug welds. | 20. Mark loader arms for insert plug welds. | ||

[[Image:LTfab20.jpg]] | [[Image:LTfab20.jpg]] | ||

21. Torch out plug weld holes. | 21. Torch out plug weld holes. | ||

[[Image:LTfab21.jpg]] | [[Image:LTfab21.jpg]] | ||

22. Grind plug weld holes. | 22. Grind plug weld holes. | ||

[[Image:LTfab22.jpg]] | [[Image:LTfab22.jpg]] | ||

23. Line up plug inserts for welding. | 23. Line up plug inserts for welding. | ||

[[Image:LTfab23.jpg]] | [[Image:LTfab23.jpg]] | ||

24. Plug weld inserts. | 24. Plug weld inserts. | ||

[[Image:LTfab24.jpg]] | [[Image:LTfab24.jpg]] | ||

25. Grind plug welds. | 25. Grind plug welds. | ||

[[Image:LTfab25.jpg]] | [[Image:LTfab25.jpg]] | ||

26. Finished inserts. | 26. Finished inserts. | ||

[[Image:LTfab26.jpg]] | [[Image:LTfab26.jpg]] | ||

27. Weld arm gussets. | 27. Weld arm gussets. | ||

[[Image:LTfab27.jpg]] | [[Image:LTfab27.jpg]] | ||

28. Arm gussets plug welded. | 28. Arm gussets plug welded. | ||

[[Image:LTfab28.jpg]] | [[Image:LTfab28.jpg]] | ||

29. Prepare pins for welding. | 29. Prepare pins for welding. | ||

[[Image:LTfab29.jpg]] | [[Image:LTfab29.jpg]] | ||

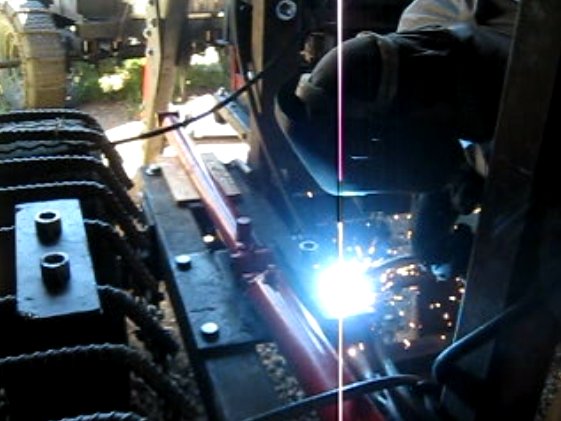

30. Weld pins. | 30. Weld pins. | ||

[[Image:LTfab30.jpg]] | [[Image:LTfab30.jpg]] | ||

31. Mount cylinder base plates. | 31. Mount cylinder base plates. | ||

[[Image:LTfab31.jpg]] | [[Image:LTfab31.jpg]] | ||

32. Mount cylinder plates to arms. | 32. Mount cylinder plates to arms. | ||

[[Image:LTfab32.jpg]] | [[Image:LTfab32.jpg]] | ||

33. Mount cylinder cross support. | 33. Mount cylinder cross support. | ||

[[Image:LTfab33.jpg]] | [[Image:LTfab33.jpg]] | ||

34. Mount cylinder arms on frame. | 34. Mount cylinder arms on frame. | ||

[[Image:LTfab34.jpg]] | [[Image:LTfab34.jpg]] | ||

35. Arm cross supports. | 35. Arm cross supports. | ||

[[Image:LTfab35.jpg]] | [[Image:LTfab35.jpg]] | ||

36. Put on real loader arms. | 36. Put on real loader arms. | ||

[[Image:LTfab36.jpg]] | [[Image:LTfab36.jpg]] | ||

37. Hang arm cross support. | 37. Hang arm cross support. | ||

[[Image:LTfab37.jpg]] | [[Image:LTfab37.jpg]] | ||

38. Torch misfit holes. | 38. Torch misfit holes. | ||

[[Image:LTfab38.jpg]] | [[Image:LTfab38.jpg]] | ||

39. Weld inner arm gussets. | 39. Weld inner arm gussets. | ||

[[Image:LTfab39.jpg]] | [[Image:LTfab39.jpg]] | ||

40. Grind inner arm gussets. | 40. Grind inner arm gussets. | ||

[[Image:LTfab40.jpg]] | [[Image:LTfab40.jpg]] | ||

41. Finish attaching cross supports. | 41. Finish attaching cross supports. | ||

[[Image:LTfab41.jpg]] | [[Image:LTfab41.jpg]] | ||

42. Finish weld arms. | 42. Finish weld arms. | ||

[[Image:LTfab42.jpg]] | [[Image:LTfab42.jpg]] | ||

43. Bolt cylinder attach plates. | 43. Bolt cylinder attach plates. | ||

[[Image:LTfab43.jpg]] | [[Image:LTfab43.jpg]] | ||

44. Attach cylinders. | 44. Attach cylinders. | ||

[[Image:LTfab44.jpg]] | [[Image:LTfab44.jpg]] | ||

45. Mount quick attach (QA) plate cylinders. | 45. Mount quick attach (QA) plate cylinders. | ||

[[Image:LTfab45.jpg]] | [[Image:LTfab45.jpg]] | ||

46. Begin attaching hoses. | 46. Begin attaching hoses. | ||

[[Image:LTfab46.jpg]] | [[Image:LTfab46.jpg]] | ||

47. Hose attachment. | 47. Hose attachment. | ||

[[Image:LTfab47.jpg]] | [[Image:LTfab47.jpg]] | ||

48. Tack weld gusset nuts. | 48. Tack weld gusset nuts. | ||

[[Image:LTfab48.jpg]] | [[Image:LTfab48.jpg]] | ||

49. Tack weld bottom cylinder support nuts. | 49. Tack weld bottom cylinder support nuts. | ||

[[Image:LTfab49.jpg]] | [[Image:LTfab49.jpg]] | ||

49.5. Tack weld cylinders. | 49.5. Tack weld cylinders. | ||

[[Image:LTfab495.jpg]] | [[Image:LTfab495.jpg]] | ||

50. Complete bottom cylinder gusset welds. | 50. Complete bottom cylinder gusset welds. | ||

[[Image:LTfab50.jpg]] | [[Image:LTfab50.jpg]] | ||

51. Botom cylinder gusset nuts welded. | 51. Botom cylinder gusset nuts welded. | ||

[[Image:LTfab51.jpg]] | [[Image:LTfab51.jpg]] | ||

52. | 52. | ||

[[Image:LTfab52.jpg]] | [[Image:LTfab52.jpg]] | ||

52. Finish weld top cylinder. | 52. Finish weld top cylinder. | ||

[[Image:LTfab53.jpg]] | [[Image:LTfab53.jpg]] | ||

=Quick Attach Plate= | ==Quick Attach Plate== | ||

60. Prep QA plate materials. | 60. Prep QA plate materials. | ||

[[Image:LTfab60.jpg]] | [[Image:LTfab60.jpg]] | ||

61. Cut stock to size. | 61. Cut stock to size. | ||

[[Image:LTfab61.jpg]] | [[Image:LTfab61.jpg]] | ||

63. Cut all tubing to size. | 63. Cut all tubing to size. | ||

[[Image:LTfab63.jpg]] | [[Image:LTfab63.jpg]] | ||

64. Mark hole locations for all pieces. | 64. Mark hole locations for all pieces. | ||

[[Image:LTfab64.jpg]] | [[Image:LTfab64.jpg]] | ||

65. Hole punch all pieces. | 65. Hole punch all pieces. | ||

[[Image:LTfab65.jpg]] | [[Image:LTfab65.jpg]] | ||

66. Prepare QA plates for welding. | 66. Prepare QA plates for welding. | ||

[[Image:LTfab66.jpg]] | [[Image:LTfab66.jpg]] | ||

67. Weld QA frame. | 67. Weld QA frame. | ||

[[Image:LTfab67.jpg]] | [[Image:LTfab67.jpg]] | ||

68. Finish welding QA plate. | 68. Finish welding QA plate. | ||

[[Image:LTfab68.jpg]] | [[Image:LTfab68.jpg]] | ||

69. Weld fingers. | 69. Weld fingers. | ||

[[Image:LTfab69.jpg]] | [[Image:LTfab69.jpg]] | ||

70. Weld bottom eyes. | 70. Weld bottom eyes. | ||

[[Image:LTfab70.jpg]] | [[Image:LTfab70.jpg]] | ||

71. Finish weld bottom eyes. | 71. Finish weld bottom eyes. | ||

[[Image:LTfab71.jpg]] | [[Image:LTfab71.jpg]] | ||

72. Weld top eyes. | 72. Weld top eyes. | ||

[[Image:LTfab72.jpg]] | [[Image:LTfab72.jpg]] | ||

74. Begin on QA mechanism. | 74. Begin on QA mechanism. | ||

[[Image:LTfab74.jpg]] | [[Image:LTfab74.jpg]] | ||

75. Finish weld eyes in place. | 75. Finish weld eyes in place. | ||

[[Image:LTfab75.jpg]] | [[Image:LTfab75.jpg]] | ||

75.5 | 75.5 | ||

[[Image:LTfab755.jpg]] | [[Image:LTfab755.jpg]] | ||

76. Finish weld eyes. | 76. Finish weld eyes. | ||

[[Image:LTfab76.jpg]] | [[Image:LTfab76.jpg]] | ||

77. Raise arms. | 77. Raise arms. | ||

[[Image:LTfab77.jpg]] | [[Image:LTfab77.jpg]] | ||

78. Extend QA cylinders. | 78. Extend QA cylinders. | ||

[[Image:LTfab78.jpg]] | [[Image:LTfab78.jpg]] | ||

79. Fit pin in QA mechanism. | 79. Fit pin in QA mechanism. | ||

[[Image:LTfab79.jpg]] | [[Image:LTfab79.jpg]] | ||

80. Mount QA plate on arms. | 80. Mount QA plate on arms. | ||

[[Image:LTfab80.jpg]] | [[Image:LTfab80.jpg]] | ||

81. Extend QA plate. | 81. Extend QA plate. | ||

[[Image:LTfab81.jpg]] | [[Image:LTfab81.jpg]] | ||

82. Weld pin pushing mechanism. | 82. Weld pin pushing mechanism. | ||

[[Image:LTfab82.jpg]] | [[Image:LTfab82.jpg]] | ||

83. Weld handle to rotation pin. | 83. Weld handle to rotation pin. | ||

[[Image:LTfab83.jpg]] | [[Image:LTfab83.jpg]] | ||

84. Mark rotation pin location. | 84. Mark rotation pin location. | ||

[[Image:LTfab84.jpg]] | [[Image:LTfab84.jpg]] | ||

85. Mount handle and push pin and bolt down. | 85. Mount handle and push pin and bolt down. | ||

[[Image:LTfab85.jpg]] | [[Image:LTfab85.jpg]] | ||

86. Put on stops and set screws. | 86. Put on stops and set screws. | ||

[[Image:LTfab86.jpg]] | [[Image:LTfab86.jpg]] | ||

87. Do same for second set of loader arms - and LifeTrac II with front and rear loaders is ready for testing. | 87. Do same for second set of loader arms - and LifeTrac II with front and rear loaders is ready for testing. | ||

=Quality Assurance= | |||

Now take tractor for a test drive: | Now take tractor for a test drive: | ||

| Line 328: | Line 405: | ||

</html> | </html> | ||

See corresponding blog post - http:// | See corresponding blog post - http://blog.opensourceecology.org/2010/09/lifetrac-prototype-ii-completed/ | ||

=Further Reading= | =Further Reading= | ||

[http://blog.opensourceecology.org/2010/07/open-source-tractor-update/ Design blog post]. | |||

Latest revision as of 17:25, 2 July 2013

Introduction

As of December 27, 2011 - we are currently working on LifeTrac Prototype IV - which features bent loader arms and Quick Connect Wheels. The new loader is File:Loaderbent.pdf. When the new wheel motors and loader arms are tested, they will be added to the official CAD. For now, we recommend replication of only the frame, unless one is a dedicated developer.

The difficulty with the motor shafts breaking involved the mislabeling of the hydraulic wheel motors by surplus center, where we discovered that the motors were simply not rated for the pressure that we used. The tractor can be built as is by replacing the wheel motors with stronger 15,000 Inch Pound Motors. The straight loader arms have poor weight balance, so we recommend building the bent loader arms of File:Loaderbent.pdf instead. These can be built by leaving the arm pivot exactly as it is, with a cut in the arms followed by welding on gussets. These arms will be optimized in the future. The quick connect wheels appear to be a robust solution.

Documents

- Computer Aided Manufacturing (CAM) Files are available for the various mounting plates. See Tractor CAM files – wheel, bearing, and motor mount plates.

Parts Manufacture

Frame

Then, build the frame.

Frame Construction Video Script [[1]]

Updated frame video:

Wheels

Wheel Assembly Video Script [[2]]

Then, prepare all the wheel mounting materials.

Then add the wheels (from Sean Church):

Lifetrac II- Wheel Mounting from Sean Church on Vimeo.

Then, go for the first test drive.

LifeTrac II Test Drive from Marcin Jakubowski on Vimeo.

Wheel Tracks

Wheel Tracks Construction video script [[3]]

Then, [build the wheel tracks.]

Extreme Traction from Marcin Jakubowski on Vimeo.

LifeTrac Hydraulics

See blog spot

LifeTrac Valves from Open Source Ecology on Vimeo.

Loader Arms

Then, build the loader arms - both front and rear.

1. Prepare loader arms.

2. Mark loader attach plates for hole locations.

3. Punch or drill mount plate holes.

4. Drill holes in loader arms.

5. Torch out arm mounts

6. Grind arm ends.

7. Drill or punch 1" holes for cylinder mount bottoms.

8. Cut pins to size.

9. Prepare bottom mount plates for loader arms.

10.Torch out 2" inserts.

11. Mark arm locations on frame.

12. Grind 2" inserts.

13. Drill 1" hole in inserts.

14. Torch out holes in frame for loader arms.

15. Smooth out holes for loader arms.

17. Fit shafts and DOM bushing for laoder arms.

18. Finish inserts.

19. Drill rear loader arms.

20. Mark loader arms for insert plug welds.

21. Torch out plug weld holes.

22. Grind plug weld holes.

23. Line up plug inserts for welding.

24. Plug weld inserts.

25. Grind plug welds.

26. Finished inserts.

27. Weld arm gussets.

28. Arm gussets plug welded.

29. Prepare pins for welding.

30. Weld pins.

31. Mount cylinder base plates.

32. Mount cylinder plates to arms.

33. Mount cylinder cross support.

34. Mount cylinder arms on frame.

35. Arm cross supports.

36. Put on real loader arms.

37. Hang arm cross support.

38. Torch misfit holes.

39. Weld inner arm gussets.

40. Grind inner arm gussets.

41. Finish attaching cross supports.

42. Finish weld arms.

43. Bolt cylinder attach plates.

44. Attach cylinders.

45. Mount quick attach (QA) plate cylinders.

46. Begin attaching hoses.

47. Hose attachment.

48. Tack weld gusset nuts.

49. Tack weld bottom cylinder support nuts.

49.5. Tack weld cylinders.

50. Complete bottom cylinder gusset welds.

51. Botom cylinder gusset nuts welded.

52.

52. Finish weld top cylinder.

Quick Attach Plate

60. Prep QA plate materials.

61. Cut stock to size.

63. Cut all tubing to size.

64. Mark hole locations for all pieces.

65. Hole punch all pieces.

66. Prepare QA plates for welding.

67. Weld QA frame.

68. Finish welding QA plate.

69. Weld fingers.

70. Weld bottom eyes.

71. Finish weld bottom eyes.

72. Weld top eyes.

74. Begin on QA mechanism.

75. Finish weld eyes in place.

75.5

76. Finish weld eyes.

77. Raise arms.

78. Extend QA cylinders.

79. Fit pin in QA mechanism.

80. Mount QA plate on arms.

81. Extend QA plate.

82. Weld pin pushing mechanism.

83. Weld handle to rotation pin.

84. Mark rotation pin location.

85. Mount handle and push pin and bolt down.

86. Put on stops and set screws.

87. Do same for second set of loader arms - and LifeTrac II with front and rear loaders is ready for testing.

Quality Assurance

Now take tractor for a test drive:

LifeTrac Prototype II Completed from Marcin Jakubowski on Vimeo.

See corresponding blog post - http://blog.opensourceecology.org/2010/09/lifetrac-prototype-ii-completed/