Hydrogen Compression: Difference between revisions

Jump to navigation

Jump to search

(Moved some stuff around) |

(Added some more categories to the page) |

||

| Line 68: | Line 68: | ||

=External Links= | =External Links= | ||

*[https://www.energy.gov/eere/fuelcells/hydrogen-and-fuel-cell-technologies-office Office of Energy Efficiency and Renewable Energy] | *[https://www.energy.gov/eere/fuelcells/hydrogen-and-fuel-cell-technologies-office Office of Energy Efficiency and Renewable Energy] | ||

[[Category: Biofuel]] [[Category: Energy]] [[Category: Hydrogen]] | |||

Revision as of 00:30, 7 October 2020

OSE Position

OSE proposes a robust economy based on water lubricated internal combustion engines running on hydrogen as a solution for distributed power production - available today using current technology with no new innovation needed outside of social innovation towards acceptance of the possibility.

Info

- Hydrogen Station Compression and Costs from NREL - [1]. Concludes cost of compression, storage, and

- Diaphragm compressor - for hydrogen - [2]

- Piston compressors provide high volume. Easier to do than diaphragm compressors. No need for ultra purity in hydrogen engines. [3]

Low Pressure Storage

- Low pressure hydrogen storage - [4] - NJ demo house.

Companies

- Pure Energy Centre - [5]

Hydrogen Cylinders

- 2000 PSI - 194 cu f (5.5 cu m) [6]

Hydrogen Generator

Separating Generator

- Diagram of system - [7]. Paper has info contacts at NREL, and comparison of PEM to alkaline.

- alkaline electrolyzer stack - price not shown - [8]

- 200 cc/min at 3-8 bar - $9k - [9]. With 1440 minutes/day - or 0.3 cu meter per day.

- 1000 cc/min - $3280 - for 1000 ml/min - 1.4 cu meter/day. Alkaline, 4 bar. That is 130 grams of hydrogen per day. [10]

- Redo the same - and 10x lower cost.

- Need 3 hours of Honda EU1000 generator - or 2.7 kWhr.

- 500 cc/min - $700 - [11]

- x5 = $3500 for 2500 cc/min or 3.5 cu m per day. Or 290 grams per day. If 0.6 gal used for 7 hours at 1/4 power, Honda EU1000 can do 3.5 hours at 200W. Nearly 1 kWhr.

- Zirfon PERL is common electrolyzer separator material - [12]. It is a polysulfone (3D printable) and 85% ZrO2 nanoparticles blend. ZrO2 - [13]

- Both stainless steel and nickel work as electrodes - [14]

- Alkaline Electrolyzer Design

DIY Separating

- thediyscienceguy@gmail.com - [15]

Mixing Generator

- $200 for 6 lpm - but this is HHO, not H + 0

- Graphite plates work well - [16]

- Wet vs dry cell design - [17]

Demonstration Hydrogen Houses

- Hopewell Project - NJ - [18]. AKA Hydrogen House - [19]

- Scientific American - Oh, only $500k for the off-grid home - [20]

Hydrogen Engines

- https://en.wikipedia.org/wiki/Hydrogen_internal_combustion_engine_vehicle

- Improving the ICE for hydrogen use - [21]

Fuel Cells

- Fuel cell types overview - [22]

- 1kW costs $5k - [23]

- 400W for 8.5k Euro [24]

- $60/W - [25]

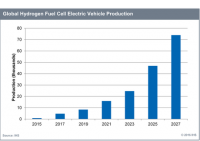

- 11k fuel cell cars exist already worldwide, half of them being in California - [26]

- From [27] -

Efficiency and Lifetime

- Efficiency from electrolysis back to electricity in fuel cells is 45% with fuel cells - p. 11 - [28]

- Lifetime of PEM FC is only 2k-4k hours in cars, and 40k in stationary applications. Major issues with longevity! [29]

Fueling Stations

- Cost approximately $1M each. OSE could fund these from proceeds of programmatic revenue in locations of OSE Campuses.