D3D Extruder: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 16: | Line 16: | ||

# Some of the bolts appear that they're supposed to be nut-less, simply catching on the 3d printed plastic. this is a bad design that doesn't work in practice. The places where there's a slot for dropping a nut catcher in perpendicular to the bolt work great, and that design should be replicated for all bolts. | # Some of the bolts appear that they're supposed to be nut-less, simply catching on the 3d printed plastic. this is a bad design that doesn't work in practice. The places where there's a slot for dropping a nut catcher in perpendicular to the bolt work great, and that design should be replicated for all bolts. | ||

[[File:constructingD3DExtruder_2018-05.jpg]] | [[File:constructingD3DExtruder_2018-05.jpg]200px] | ||

[[File:printingD3DExtruder_2018-05.jpg]] | [[File:printingD3DExtruder_2018-05.jpg]200px] | ||

=CAM (3D Print Files of Modified Prisa i3 MK2)= | =CAM (3D Print Files of Modified Prisa i3 MK2)= | ||

Revision as of 02:48, 1 July 2018

Versions

MK8

- D3D first version - MK8 extruder - File:D3D Extruder.fcstd

Modified Prusa i3 MK2

- D3D second version - Prusa i3 MK2 Original - OSE Adapted - Extruder - File:Prusa i3 mk2 extruder adapted.fcstd

2018-06 Notes

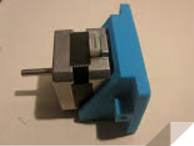

These were noted by User:Maltfield when he attempted to build the D3D extruder from the part files on this wiki in 2018-06.

- There is a hole missing in extruder body which should receive the bolt for mounting motor

- Some of the bolts appear that they're supposed to be nut-less, simply catching on the 3d printed plastic. this is a bad design that doesn't work in practice. The places where there's a slot for dropping a nut catcher in perpendicular to the bolt work great, and that design should be replicated for all bolts.

[[File:constructingD3DExtruder_2018-05.jpg]200px] [[File:printingD3DExtruder_2018-05.jpg]200px]

CAM (3D Print Files of Modified Prisa i3 MK2)

3d printable parts extracted to stl from the freecad file above:

- File:Prusa i3 mk2 extruder adapted body.stl

- File:Prusa i3 mk2 extruder adapted cover.stl

- File:Prusa i3 mk2 extruder adapted idler.stl

- File:Prusa i3 mk2 extruder adapted fanNozzle.stl

- File:Prusa i3 mk2 extruder adapted bearingShaft.stl

- File:Prusa i3 mk2 extruder adapted interface.fcstd - File:Prusa i3 mk2 extruder adapted interface.stl

BOM

CAD File Downloads

Simple Extruder Holder

- FreeCAD -File:Motor interface.fcstd. I used M4 nuts for the nut catcher, but for the screws I used added the https://www.mcmaster.com/#90116a217/=14gcc4s that are already in the universal axis, in order to avoid adding a new item to the BOM

- STL - File:Motor interface.stl

Working Document

Development Document

BOM

- Use this extruder - [1]

Exploded Part Diagram

Part Files

3D Printed

- Extruder Idler - File:Idler.stl - File:Idler.fcstd

- Extruder carriage side - File:Carriage side.stl - File:Carriage side.fcstd

- Extruder motor side - File:Motor size.stl File:Motor side.fcstd

Other Parts

- Stepped motor - File:Nema17.stl - File:Nema17.fcstd

- Pulley - File:Pulley.fcstd - File:Pulley.stl

- 8mm bearing - File:8mm bearing.stl - File:8mm bearing.fcstd

- E3D V6 - File:E3Dv6.stl - File:E3Dv6.fcstd

Fasteners

Tech Tree of Choices

We go from Tech tree of choices -> Industry Standards -> Technology Assessment -> Value Proposition

- These are all the different ways to implement an extruder for a 3D printer.

- Hit Ctrl-mouse scroll to zoom in