3D Printed Electric Motor: Difference between revisions

Jump to navigation

Jump to search

AbeAnderson (talk | contribs) |

|||

| Line 12: | Line 12: | ||

:*260g | :*260g | ||

:*Not bad. | :*Not bad. | ||

==Axial with HalBach Array== | |||

*https://www.emworks.com/ckfinder/userfiles/files/Axial%20Flux%20Motor.pdf | |||

=Radial Flux= | =Radial Flux= | ||

Revision as of 23:30, 24 September 2019

Axial Flux

- Dual rotor 500W motor with controller. Best starting point for a motor. - [1]

- Most complete plans

- has 8 kW version as well

- Late 2018, TU Delft students on axial flux coreless - [2]

- John Reimers - early 2019 - McMaster U grad student - [3]

- French student project - no plans - [4]

- 100W, about 1 in lb torque - 7000 RPM - so 70 RPM geardown gets you 100 in lb. Comparable to current motors.

- 260g

- Not bad.

Axial with HalBach Array

Radial Flux

- Thingiverse - [5]

- Generator - https://www.thingiverse.com/thing:2635188

Halbach PMDC

- MakeSEA 600W motor - [6]. MakeSEA 40 and 90W - 0.06 peak Nm torque - about 70% efficiency. MakeSEA 60W -[7]

- Testing on an ultralight aircraft with 600W motor - [8]

- French project - radial motor - .14 Nm torque - 100W - [9]

- Small Halbach array generator - 7W per 1000 rpm - [10]

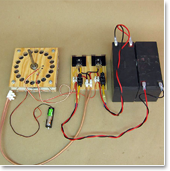

PMDC

- Great scott - [11]

Linear

- Model steam engine - Solenoid Model Steam Engine

Simple BLDC Outrunner

- Including Howto - [12]

- Inrunner BLDC with embedded 3D printing from the WM Keck Center for 3D Innovation - [13]

PCB Motor

- Circuit mill + 3DP - axial flux - [14]. By Carl Bugeja

3 Phase BLDC Simple Jet Motor

- Magnets + coils. Doea lack of a magnetic core make it very inefficient, or can this do well upon geardown? High speed geardown is not easy, though. [15]

- Isn't this a ducted fan, not a pule, turbo, or ram jet etc?

Alternator - Axial

- Decent at low speed - [16]