CNC Torch Table v19.10: Difference between revisions

No edit summary |

|||

| Line 58: | Line 58: | ||

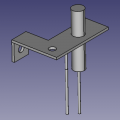

File:IdlerShort.PNG|[[File:IdlerShort.FCStd]] - Short Idler to take flanged bearing | File:IdlerShort.PNG|[[File:IdlerShort.FCStd]] - Short Idler to take flanged bearing. Short Idler STL - [[File:IdlerShort.stl]] | ||

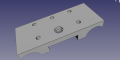

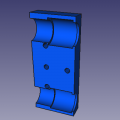

File:Cnc_torch_half_carriage_v19_10.png|Half carriage for auto alignment - [[File:Cnc_torch_half_carriage_v19_10.fcstd]] - STL - [[File:Cnc_torch_half_carriage_v19_10.stl]] | File:Cnc_torch_half_carriage_v19_10.png|Half carriage for auto alignment - [[File:Cnc_torch_half_carriage_v19_10.fcstd]] - STL - [[File:Cnc_torch_half_carriage_v19_10.stl]] | ||

Revision as of 10:36, 2 December 2019

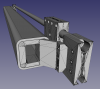

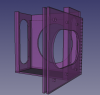

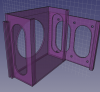

CAD 1" Universal Axis - 3 Pieces

Frame

Mechanical

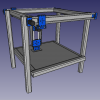

Final assembly of CNC torch table. FreeCAD at Gitlab -[1]

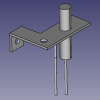

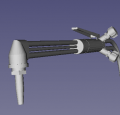

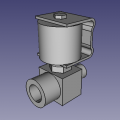

Assembly of Z axis with gas solenoids. Gitlab - [2]

File:YAxisAssembly.FCStd - Assembly of Y axis

File:Cnctorchidlerassy.fcstd Idler assembly for final assembly via merge workflow.

File:1inchshaft.fcstd One inch front side shaft.

608 skateboard 8x22x7 mm Bearing. Download - File:608Bearing.FCStd

Flange for 608 bearing. Download - File:BearingFlange.FCStd

Bushing for Flanged bearing. Download - File:BearingBushing.FCStd

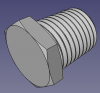

- Torchidlerbolt.png

Bolt for CNC torch table idler to frame attachment. Download - File:608Bearing.FCStd

Stock tubing library. Download - File:FreeCAD Tubing Library.tar.gz. See more information at Quarter Inch Stock Tubing

Parametric 4x4 tubing - File:4x4Tube.FCStd.

End Plug to join Idler to 4x4 tubing - File:EndPlug.FCStd.

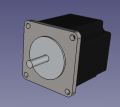

File:Nema23motor.fcstdNema 23 motor.

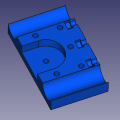

File:CNC Torch 1708 Motor interface.fcstd

. STL for printing - File:CNC Torch 1708 motorside.stl

. STL for printing - File:CNC Torch 1708 motorside.stl

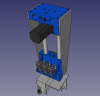

File:CNC Torch 1in carriage module.fcstd Has the shortened and longer printed piece.

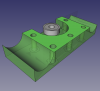

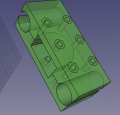

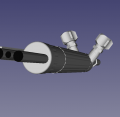

File:Cnc torch idler v19 10.fcstd Idler with full carriage contact. STL - File:Cnc torch idler v19 10.stl

File:Torch.fcstd Torch Handle.

File:Torch tip.fcstd Torch Handle.

File:Torch handle only.fcstd Torch Handle.

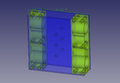

File:Cnc torch carriage v19 10.fcstd - carriage with nut catchers in top and bottom. STL - File:Cnc torch carriage v19 10.stl

Peg for 15mm G2 belt - File:Cnc peg 15mm belt v19 10.fcstd - STL - File:Cnc peg 15mm belt v19 10.stl

File:IdlerShort.FCStd - Short Idler to take flanged bearing. Short Idler STL - File:IdlerShort.stl

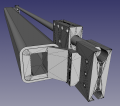

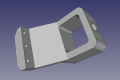

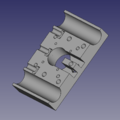

Half carriage for auto alignment - File:Cnc torch half carriage v19 10.fcstd - STL - File:Cnc torch half carriage v19 10.stl

Igniter for acetylene cut torch

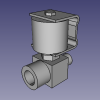

FreeCAD - File:Igniter.fcstdEM valve for acetylene and oxygen

FreeCAD - File:Fl 205 cut of solenoid.fcstd1/4" Plug.

FreeCAD - File:Quarterplug.stl

Electronics

Control Panel - FreeCAD -File:Controlpanel v1904.fcstd. Bent panel STL - File:Bentpanel v1904.stl

D3D v19.04 Power Supply - FreeCAD -File:Powersupply v1904.fcstd

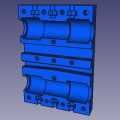

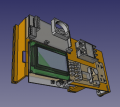

RAMPS 1.4 - FreeCAD -File:RAMPS14 v1904.fcstd. Full detailed file - 4MB - [3]

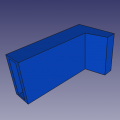

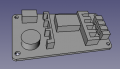

Stepper driver - FreeCAD -File:Stepperdriver v1904.fcstd. File for detailed LCD controller and endstop can be found at [4]

Solid state relay - FreeCAD -File:Ssr v1904.fcstd. Source: [5]. See Fotek SSR. Dimensions verified with Amazon source.

Reprap Discount Smart Controller - FreeCAD -File:Smartcontroller v1904.fcstd. Source: [6].

Ground Fault Connection Interrupt (GFCI) outlet - FreeCAD -File:Gfci v1904.fcstd. CAD source at McMaster Carr: [7]. May not represent actual GFCI.

File:Tb6600.fcstd Toshiba 6600 stepper driver. Source: [8]

12V Power Supply for gas solenoids and steppers. File:12Vps.fcstd.

Auxiliary control panel. File:Auxcontrolpanel.fcstd. STL - File:Auxcontrolpanel.stl

Concept

Universal Controller Automation

=Concept Video Walk-Through=

BOM

- Impco FL-205-1 valves - [9]

- Impco Et98-52295 valves - [10]

- Brass 90° Elbow 1/4" NPT Male to Female - [11]

- 40 micron Inline Gas Filter - [12][13]

- Idler Bearing - [14]

- Spring steel - 0.049" - [15] and 0.075" - [16]

- Split Wire Loom - 1.5"

- Angle barb - 1/4" - [17]

Firmware

Download firmware: File:Marlin v19.10.CNCTorch.zip

- To use no temperature sensors, set max temps to 500 and jumper the thermistor pin pairs. Jumpering sets temp to max, which is 358C. Result: does not work. MAXTEMP error is still triggered.

- So instead in Configuration.h:

- define HEATER_0_MINTEMP -1

- define BED_MINTEMP -1

This works. Without thermistors, RAMPS reads 0C. Set the minimum below that, and MINTEMP ERROR is avoided.

Build

X axis, carriage, end plug for hanging 1" Universal Axis around 4"x4" stel tube:

![Final assembly of CNC torch table. FreeCAD at Gitlab -[1]](/images/thumb/3/35/Torch_table_assembly_v19_10.png/120px-Torch_table_assembly_v19_10.png)

![Assembly of Z axis with gas solenoids. Gitlab - [2]](/images/thumb/5/58/Zassembly.png/120px-Zassembly.png)

![RAMPS 1.4 - FreeCAD -File:RAMPS14 v1904.fcstd. Full detailed file - 4MB - [3]](/images/thumb/a/a5/RAMPS14_v1904.png/120px-RAMPS14_v1904.png)

![Stepper driver - FreeCAD -File:Stepperdriver v1904.fcstd. File for detailed LCD controller and endstop can be found at [4]](/images/thumb/a/a8/Stepperdriver_v1904.png/120px-Stepperdriver_v1904.png)

![Solid state relay - FreeCAD -File:Ssr v1904.fcstd. Source: [5]. See Fotek SSR. Dimensions verified with Amazon source.](/images/thumb/b/ba/Ssr_v1904.png/120px-Ssr_v1904.png)

![Reprap Discount Smart Controller - FreeCAD -File:Smartcontroller v1904.fcstd. Source: [6].](/images/thumb/f/fe/Smartcontroller_v1904.png/120px-Smartcontroller_v1904.png)

![Ground Fault Connection Interrupt (GFCI) outlet - FreeCAD -File:Gfci v1904.fcstd. CAD source at McMaster Carr: [7]. May not represent actual GFCI.](/images/thumb/5/50/Gfci_v1904.png/117px-Gfci_v1904.png)

![File:Tb6600.fcstd Toshiba 6600 stepper driver. Source: [8]](/images/thumb/0/05/Tb6600.png/120px-Tb6600.png)