Silage: Difference between revisions

Jump to navigation

Jump to search

m (changed order of figures) |

(Breadcrumb template) |

||

| Line 1: | Line 1: | ||

{{ | {{Breadcrumb|Food and Agriculture|Animal Husbandry}} | ||

{{ | {{Breadcrumb|Energy|Biofuel}} | ||

{{ | {{Breadcrumb|Materials|Bioplastics}} | ||

[[File:silage01.jpg|370px|thumb|right|Flat silo - The lactic fermentation process is already finished after about 2 weeks. The lactobacilli produce so much lactic acid that the pH drops considerably, ending up somewhere near 4. That's too low even for the lactobacilli, so that they die too. Nothing will grow and the whole thing is well-preserved, possibly for years.]] | [[File:silage01.jpg|370px|thumb|right|Flat silo - The lactic fermentation process is already finished after about 2 weeks. The lactobacilli produce so much lactic acid that the pH drops considerably, ending up somewhere near 4. That's too low even for the lactobacilli, so that they die too. Nothing will grow and the whole thing is well-preserved, possibly for years.]] | ||

Revision as of 20:29, 29 April 2011

Main > Food and Agriculture > Animal Husbandry

Main > Materials > Bioplastics

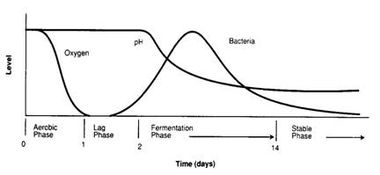

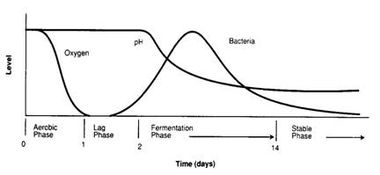

Flat silo - The lactic fermentation process is already finished after about 2 weeks. The lactobacilli produce so much lactic acid that the pH drops considerably, ending up somewhere near 4. That's too low even for the lactobacilli, so that they die too. Nothing will grow and the whole thing is well-preserved, possibly for years.

The first phase should be as brief as possible to maintain the quality of the silage. Excessive aerobic fermentation reduces the energy content of the silage and may cause heat damage to proteins.

The second or anaerobic phase begins when available oxygen is used up by respiration and aerobic bacteria cease to function. Anaerobic bacteria (bacteria that grow in the absence of oxygen) then begin to multiply rapidly and the fermentation process begins.

The best silage is produced when the most rapidly growing microorganisms are predominately of the lactobacilli species, as they produce lactic acid from the fermented plant material. Lactic acid lowers the pH of the silage. Fermentation completely ceases after three to four weeks when the pH becomes so low that all microbial growth is inhibited.

(Source: Nutritional Ecology of the Ruminant, P. Van Soest, Cornell University Press, 1994, p. 217.)

The second or anaerobic phase begins when available oxygen is used up by respiration and aerobic bacteria cease to function. Anaerobic bacteria (bacteria that grow in the absence of oxygen) then begin to multiply rapidly and the fermentation process begins.

The best silage is produced when the most rapidly growing microorganisms are predominately of the lactobacilli species, as they produce lactic acid from the fermented plant material. Lactic acid lowers the pH of the silage. Fermentation completely ceases after three to four weeks when the pH becomes so low that all microbial growth is inhibited.

(Source: Nutritional Ecology of the Ruminant, P. Van Soest, Cornell University Press, 1994, p. 217.)

Silage is the preservation of green fodder in a silo by means of lacto-fermentation. It relies largely on lactobacilli, especially Lactobacillus plantarum, and is thus similar to the way in which Sauerkraut and Kimchi are preserved.

Advantages and Disadvantages

Advantages:

- weather at harvest time is largely irrelevant

(make hay while the sun shines) - often has better nutrient preservation than hay (=> healthier, happier cows)

- wide range of crops can be used (see below, "feedstocks")

- weedy harvest can be used - get rid of weed seeds in the process

- large quantities can be stored, preserved for years

- no need for further processing

- even horses can be fed with silage, although the process is tricky and somewhat different from that for regular silage

Disadvantages:

- harvest is heavier than hay, i.e. somewhat higher initial energy input is required

- high weight and water content means that silage cannot be transported very far, therefore has low commercial value

- equipment may be more expensive than that used for hay

- infrastructure for storage may have to be built (silo)

- when plastic sheets are used, there will be plastic waste that creates waste issues / has to be recycled.

- effluent from silage is very acidic and rich in nitrogen (nitrates) - a potential serious pollutant

- silage odor !

Suitable feedstocks

grass crops, corn (maize), sorghum, cereals (wheat, oats), hemp, beans, clover, sunflowers, ...

Applications and Product Ecology

- the traditional use: as livestock fodder for ruminants (cattle, goats, sheep)

- feedstock for anaerobic digester to make biogas (popular: corn silage)

- silage contains abundant lactic acid (duh!) - a major platform chemical for organic chemistry

- lactic acid is the basic feedstock for many biodegradable bioplastics such as PLA. In a process described here, silage is pressed and the liquid harvested for its amino acids and lactic acid. The remaining fibrous cake can still be used as fodder for livestock or as biomass for other uses (combustion, pyrolysis, biochar, perhaps as mulch ...).

- bioplastics are also needed to make silage bales or silage tubes

- compressed earth bricks to build a permanent vertical silo

- there is often a nitrogen-rich, often highly acidic liquid that drains from larger silos (effluent). It can be used as liquid fertilizer (example here), for growing duckweed, or in hydroponics (although it may have to be buffered first).

- effluent can be used to clean up soils which are contaminated with heavy metals [1]

- effluent may be suitable for "charging" biochar with nutrients (untested idea, but high likelihood of working)

- filter any vented air through a charcoal filter (char later becomes biochar), to reduce smell

- large scale carbon sequestration: carbon in silage is stable for a long time, does not go back to atmosphere until exposed to oxygen

- (speculative, unproven:) is it possible to grow maggots on silage ? (use for aquaculture and as chicken/duck food)

Links

- Wikipedia: Silage, polylactic acid and PLA shrink film for packaging