3D Printer Log

Relevant logs are Marcin_Log, Tobben_Log, Joshua_Log,[[TakacsLog] and Michel Log

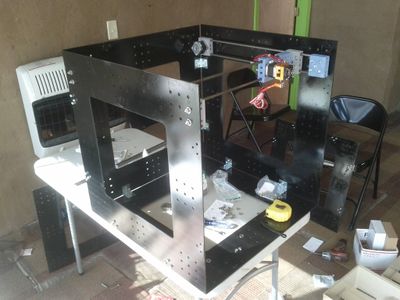

Saturday Oct 30, 2016

- begin assembly of printer at FeF

- created spacer parts to assist in keeping plates aligned

- needed to source M6x30 socket head bolts to attach one Universal CNC Axis to the carriage of another.

- eight total, 2 for each side of extruder axis and 2 for the carraige of the Zaxis and 2 to mount build plate

Fri Aug 25, 2016

Bas, Andrea, Michel, Jonathan, Marcin.

- Bas + Gerry Anzalone + Mark (a teacher). Using Athena printer - 2 people build a single Athena printer in 1 day. Run + calibrate + software the second day. Runs Franklin. Supplies all open source programs - 300 3D printers built. This summer 150 printers were built.

- http://www.3d4edu.com/

- Mark + Bas - http://phidiasllc.com/

- Andrea - program manager in the IT sector, for cloud services. Provide virtualized server, with open source server and services. Easy deployed by other organization. Virtualized server - take one server, and install hypervisor - vmware - proxmox https://www.proxmox.com/en/ - softeware layer that emulates other servers. Perhaps Debian and Centos.

- Andrea is working on server infrastructure for OSE

- Templates on top of mediawiki - Andrea - wikifab.org -

- Clement & Pierre - on MediaWiki templates.

- France - Hemp Decorticator - full chain of tools to extract tissue -

- Route - Beagle Bone Green + RAMBo.

- Franklin for height control.

- Raspberry pi zero - https://thepihut.com/products/raspberry-pi-zero

- http://www.appropedia.org/Athena_Franklin

- http://makezine.com/2013/04/15/arduino-uno-vs-beaglebone-vs-raspberry-pi/

- https://github.com/mtu-most/franklin/blob/master/calibrate/rambo.ini

- https://www.adafruit.com/products/981?gclid=CNO93qax3c4CFYQAaQod4YQARg

- https://www.adafruit.com/products/2992

- https://www.adafruit.com/product/2885

- Franklin Wiki -https://github.com/mtu-most/franklin/wiki

- Follow video on Appropedia Franklin - for install direction. Requires oxygen, oxypi, graphis. [1]

- Geetech RAMBo - [2]

Sat Aug 20, 2016

Mon Aug 22, 2016

RAMBo open source controller. Extensibility to >2A can be addressed by connecting outputs of the RAMBo to a larger stepper driver via the step + direction pins.

Wed Aug 17, 2016

See working Google Presentation for development - [3] as well as 3D Printer Design Evolution.

Thu Jul 14, 2016

Working document is 3D Printer Design Evolution.

Sat Jan 23, 2016

Added 'latest team meeting' video to D3D Development. Jonathan joins team. Planning Factor e Farm build data collection next week, and with those results, we will go forward with improvements prototyping with Jonathan Kocurek, Torbjorn Ludvigsen, and possibly Joshua Langevin and Will Bombardier.

Wed Jan 20, 2016

Purchased a Prusa i3 kit from Folger Technologies, the aluminum extrusion version. Goal is to evaluate build, and see what it takes to do a one day build - and determine more specific value proposition as far as how to present the workshop. Considering auto bed level addition - reviews say that calibration is a big issue, and in our case, can be a show-stopper for a one day build. 2 people per team can make it happen more easily if we design for parallel process - definitely doable. I have seen reports of 7-24 hours for the complete build until good printing.

December 23, 2015

Started D3D Development - "The world's first one day, economically sustainable 3D printer build workshop for a 3D Printer that works."