D3D Ohio v18.02

Build

Extruder teardown and build- https://docs.google.com/presentation/d/1KIu1cxAdYsfQuMsC22vkaRgfDtb8w9GjL_zW0v-OKbw/edit?usp=sharing

D3D extruder build

Photos of build: https://photos.app.goo.gl/P3TpbyrDfRtszzoX6

Issues and notes:

- Needed to file down 3d printed rod for bearing idler.

- drilled out several areas.

Tools found to be helpful:

- Picks(dental size)

- drill and bit to finish holes.

- punch, hammer and vice to lightly set in square nuts (my holes were a bit small)

- hobby knife set for finishing holes. a plain razor blade is also good. WEAR PROTECTIVE GLOVES AND ALWAYS CUT AWAY FROM SELF

-ADD HERE 1. List of steps, and parts needed per step. 2. Starting list of required, and helpful tools 3. with pictures, grab shots of caliper measurements often and whenever appropriate.

Basics

- A variation of the D3D 3D Plastic FDM Printer that has a 12 inch print bed, Made with a PVC frame

http://opensourceecology.org/wiki/D3D_Extruder

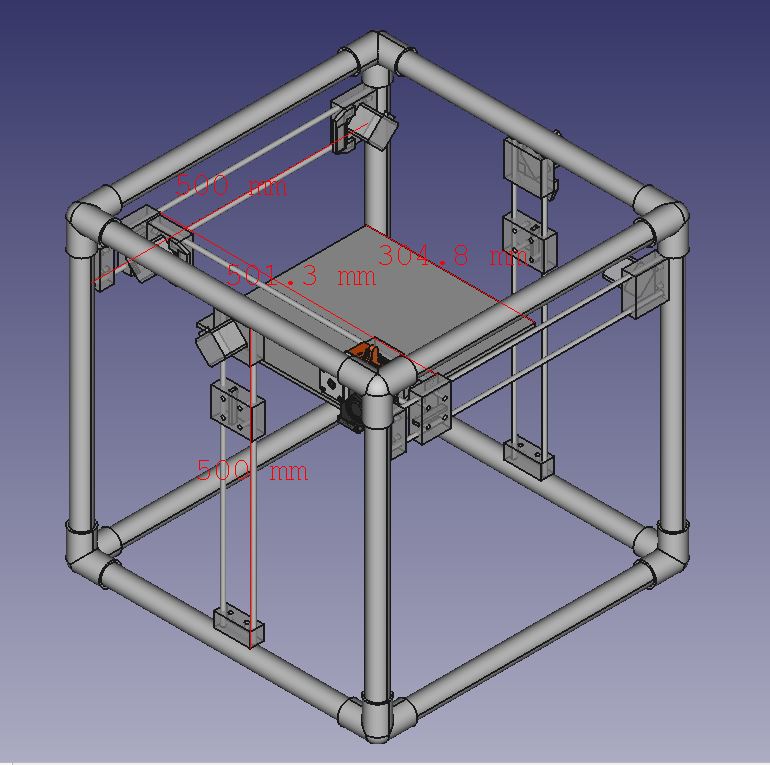

CAD

Most recent Render: http://opensourceecology.org/wiki/File:D3D_OHIO_18.01_V0.3_WIP.fcstd

BOM

- Sensor - 8 mm sensing - 18 mm diameter - [1]

Users Prusa I3 Extuder module Prusa I3 MK2 here. the replication of this module used in the D3D ohio v18.02 is here: https://wiki.opensourceecology.org/wiki/D3D_Extruder_v1807 https://wiki.opensourceecology.org/wiki/D3D_Extruder

Modeling

The intention of this section is to show the most up-to-date CAD module visually as it is developed. Versus the development log, this will attempt to show the "best" work or "Stable" versions

V1.0.0 Latest version uploaded.

-Uses short idler. 500mm steel rods. allows for an extra inch on x and y axis.

V0.3 DONE - This will be a rendering with 1" PVC tube and corners, 12" bed and a http://opensourceecology.org/wiki/File:Prusa_i3_mk2_extruder_adapted.fcstd extruder changed for what is currently present in V0.2

This file has been uploaded as is, currently we just have some part movement and a 12" bed

FILE V1.0

12" bed. check calcs for measurements. File:D3D OHIO 18.01 V0.3 WIP.fcstd

Video

Packing

Development

[WIP NEEDS DONE}

Development Log

8/4/2018

-worked on drilling and mountings for D3D PVC. testing cuts and cutting methods with .5" scrap them moving to 1" pipes. https://photos.app.goo.gl/Km166hmZpXR9EKHQ9

-updated calcs with screw sizes found and other details. https://photos.app.goo.gl/PjMYwAJp2ibobuVW6

7/17/2018 to 7/29/2018

- All parts for D3D extruder have been ordered and arrived.

- Recieved a Prusa I3 that WORKS and can now PRINT.

https://photos.app.goo.gl/m48aZE4RAawdjJKU7

- took printer to a company hackathon and demonstrated the Universal axis. Measured and ordered screws that will work for mounting the axis to .5" and 1" PVC pipes

6/01/2018 to 7/16/2018

Attempted to get mark 8 extruder functional this failed. during this time, ordered extuder parts from Steven (OSE).

The arrived parts did not fit my specific J-head hot end.

Was refered to this BOM https://docs.google.com/spreadsheets/d/1WNRJfb56ilHlIcdcz5cS92sy0QnUK5MiNVzNW1Jf7Lc/edit#gid=0

and this part https://www.ebay.com/itm/DUAL-E3D-V6-J-head-Direct-Hotend-Kit-1-75-12V-All-Metal-Throats-Hot-End-USA-/292208050774?hash=item4408f50256:g:MkEAAOSwKJRZicAS which provided a secure fit once purchased.

Currently waiting on family fianicial situation to improve with a recent layoff, then Will grab the rest of the componets needed (MISC screws and other parts) may also get a ali-express order of the parts as they are affordable, but take longer to get here.

5/27/2018 to 6/01/2018

Hiatus due to day job - commission a sewer lift station

5/27/2018

Summary:

- Finish belt routing

- more electronics work

- Axis mounting on frame

- Research on how rods are used to hold up the z axis?

5/20/2018

Summary: Routed the tension belts for uAxis's... started setting up electronics

Some issues and questions:

- How do I do the heated bed? Sil. Pad under alum, then plastic printing sheet attached to alum?

- Found some instruction here: http://opensourceecology.org/wiki/D3D_PVC_pipe_8in_bed and here:

- Issues today getting a print from old printer with newest ordered J-Head and Mark-8 extruder from Geeetech... jammed and removing jam with acetone.

-Where can I just buy a working extruder for now? I need to print or grab a printed version of our adopted extruder.

Ideas and innovations Had and idea for a magnetic adaptor for frame mounting Could I make a device that is PVC printed that allows the D3D frame to grab on to a PVC fitting with magnets?

- Would be Two clamshells, perhaps the interior features would be jagged, or sprayed with spray rubber.

- Perm. magnets at either end for grip.

- One of the clam-shells would have a place for a screw to pass compleatly though

- would make the frame a small bit bigger. would be nice to have this Grab onto the PVC versus drilling though it

5/8/2018

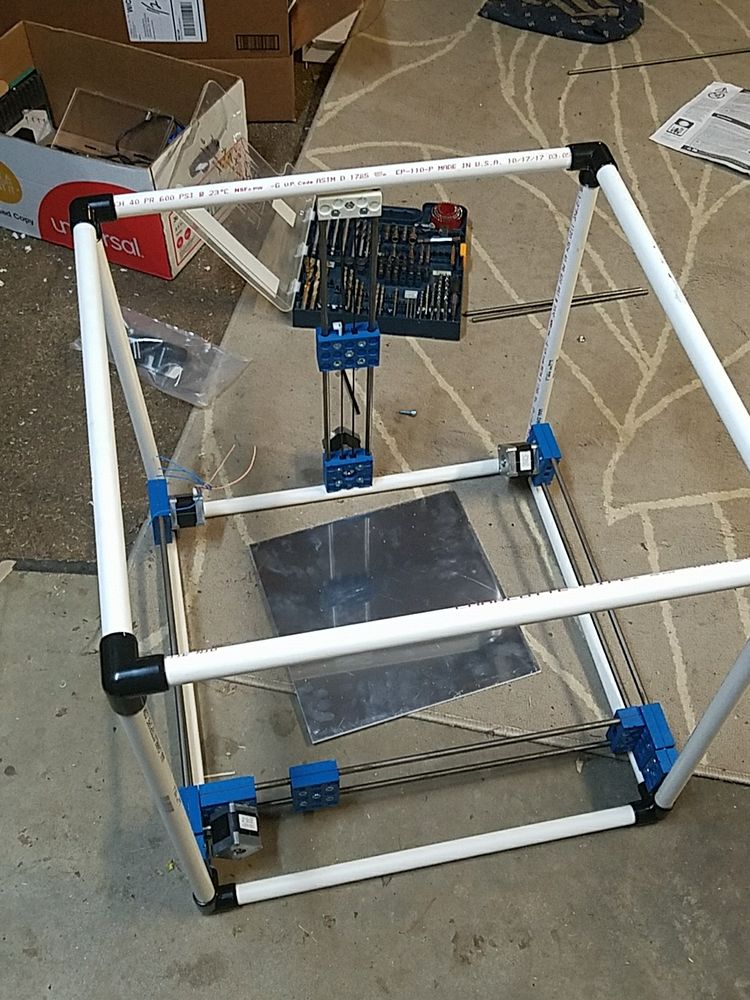

To get this up to date, the CAD is rendered.

Today, I am assymbuling the printer. I have 4 of the Universal Axis Units built, but only have the timing belt in one of them.

GOAL: From today, I am going to try and cut the PVC pipes.

11:30 From the D3D frame gen, I have a pipe length of precisely 493.546mm that's 19.43094488"... so, I'll rationalize this down to 19 1/25" because then, you can push the pipe in so it totally snugly grabs around the corner fitting. I'll see how this cut works.

all cuts took a half hour. I like this fit. ! Pictures as soon as I get my file server up again... Update 5/20 picture of build at this time:

3/2/2018

Found a Basis for a render http://opensourceecology.org/wiki/File:Medium_Size_Version_12_in.FCStd

I have a great deal to learn in Freecad on more adv. assym work. Such as how There are parameters for assymblies, and there is a linked parameter for rod lenght between the Right and left Y universal axis so you can change lenght in one spot. super cool.

See Also

- D3D

- 3d Printing Techniques

- Open Source Digital Fabrication Construction Set

- D3D 1612 Product Manual

- TakacsLog

Useful Links

- Here is a note on the simplified model - https://www.youtube.com/watch?time_continue=38&v=Epit8c9zp8Q

- here are the simplified models we will build this off of past v0.3:http://opensourceecology.org/wiki/D3D_CNC_Circuit_Mill

- http://opensourceecology.org/wiki/3D_Printer_Genealogy

- https://www.youtube.com/watch?v=a7XAZhXt6Hk&feature=youtu.be

- D3D v18.02 BOM

- http://opensourceecology.org/wiki/D3D_Part_Library#Assembly_Index - This is all of our D3D assy. modules so far.

- http://opensourceecology.org/wiki/File:Prusa_i3_mk2_extruder_adapted.fcstd Extruder we will use

- http://opensourceecology.org/wiki/D3D_Instructional_videos_for_April,_29th,2017_Workshop << helpful instructions for temporary ref.

- http://opensourceecology.org/wiki/D3D_PVC_pipe_8in_bed