Biodigester Part Library

Basics

- A unit that takes in Black Water and turns it into Biogas , Digestate , and Leachate

As Built

More pictures - search Biodigester at https://www.facebook.com/marcin.jakubowski.378/ or at https://www.facebook.com/groups/398759490316633/

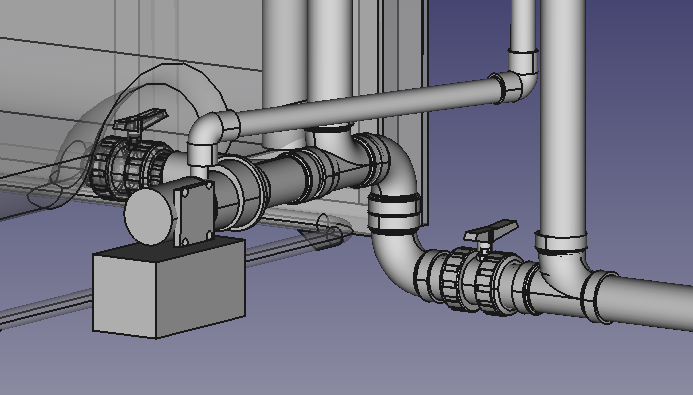

CAD

Pictures

Quality documentation. Google Photos Album- [1]

Quality documentation. Google Photos Album- [1]

2025 Version

BOM and Build

Build Procedure and Notes

Build Documentation

Heat Enclosure

Technical Design + Calculations

Biodigester Inlet

- See Biodigester Inlet - this is the Sink Blackwater System.

Potential Future Additions

- Automated sludge removal (auger and perhaps a de-waterer)

- Packing/Growth Media (small light objects like bioballs) for increased biofilm growth area (may work, see research below)

- See Powdered Activated Carbon Treatment

- Additional aggitation (preferably constant)

- Paddle/Impellor would work, but would carry a tangle/clog risk (espeically if using a "recirculating pump" type setup)

- Inert gas micro-bubble diffuser?

- Sensors (Temp, PH, etc)

Concept: 2 Tote Biodigester

Scaling up to 48 People

- 1 showers and toilets per 8 people - [2]

Analysis of the Solar Cities' Biodigester Design

See tight explanation:

See simple build:

Janice Kelsey runs (not CSA but) ASC effort - Agriculture Supported Community - https://www.linkedin.com/in/janicekelsey

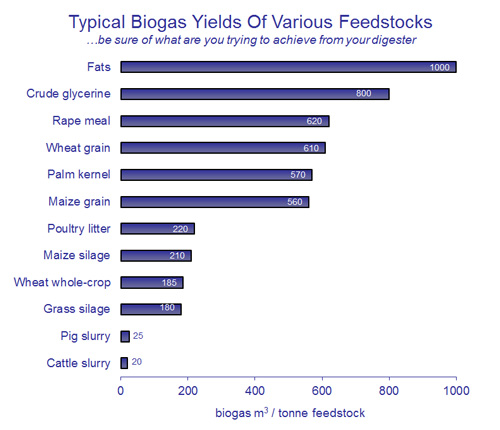

Feedstock Yields

Source: [3]. Another source appears to verify this - [4]

Pathogen Risk

"Wastes of animal and human origin, used as AD feedstock, contain various pathogenic bacteria, parasites and viruses. Pathogenic species that are regularly present in animal manures, slurries and household waste are bacteria (e.g. Salmonellae, Enterobacter, Clostridiae, Listeria), parasites (e.g. Ascaris, Trichostrangylidae, Coccidae), viruses and fungi. Co-digestion of abattoir and fish-processing wastes, sewage sludge and biowaste increases the diversity of pathogens that are likely to be land-spread and could enter the animal and human food chains" Biogas Handbook p.105-106

Pathogen Risk Mitigation

"Effective pathogen reduction in digestate is provided by implementation of a separate presanitation process, for the feedstock types which require special sanitation (e.g. waste waters from slaughter houses, food and catering wastes, flotation sludge). For feedstock types which do not require separate sanitation (animal manure and slurries, energy crops, vegetable residues of all kinds) the necessary sanitation and pathogen reduction is ensured by the AD process itself. Some process parameters, such as temperature, retention time inside the digester, pH etc., have direct or indirect influence on the sanitation efficiency of the AD process.

Temperature

The process temperature has a sanitation effect on the supplied substrates. In case of pretreatment of feedstock, the efficiency of pathogen reduction increases with the increasing temperatures.

Retention time

In the case of biogas plants treating animal manure and slurries, vegetable biomass from farming activities as well as other non-problematic feedstock types, sanitation is a result of combined temperatures and MGRT. The influence of temperature and MGRT on destruction of pathogens is highlighted in Table 9.4, showing decimation times for some common pathogen types from animal slurries. In case of e.g. Salmonella typhi murium, the destruction of 90% of the population occurs in 0,7 hours in a digester running at 53oC (thermophilic digestion), in 2,4 days in a digester operating at 35oC (mesophilic digestion), but the same reduction of Salmonella can take 2 to 6 weeks at ambient temperature, in untreated slurry.

Digester system

In fully mixed digesters, the fresh feedstock can always contaminate the already sanitised substrate. Even in a plug flow reactor, where the particles move evenly through the reactor, short cuts cannot be prevented. Therefore, a minimum retention time in mixed reactors cannot be fully guaranteed. This can only be ensured in a batch (discontinuous) system, where the digester is firstly filled up and then completely emptied after digesting (e.g. batch method of dry AD system)."

Post treatment and sterilization

"Biodigester effluent may also be treated in a secondary treatment phase such as Ultrafiltration, Ultraviolet Light (UV), a Treatment Wetland, Composting, or Aerobic Treatment [5]. Ultra filtration consists of running the effluent through a membrane that only allows solubles to pass through. At the moment this technology is more likely to be used in the developed world but appropriate solutions using materials such as mangroves and other plants might be used. Ultrafiltration is practical for concentrated wastewaters that have had most solids settled out. UV treatment is a common water treatment technology however may only be practical for dilute effluents where turbidity is not an issue. A treatment wetland provides additional treatment as well as habitat for wildlife. Essentially a movement gradient is created and planted with wetland plants that facilitate nutrient and pathogen removal. This is the way wastewaters, such as storm runoff, are naturally treated in the environment. A composting process maybe allowed used to treat the effluent however it must first be dried to facilitate aeration, which is land and energy intensive. Care must be made to ensure that no one breathes in the dust from the fresh effluent during this process. The effluent may also go through an aerobic treatment process to polish the effluent however this is expensive, intensive, and removes nutrients from a productive system. Other waste treatment options may include sand filters and clarifiers." Biogas from human waste

Long Term Maitnence

Pump + Probes etc Cleaning

- Biofilms and sludge will most likely build up over time

- Thus every x ys, these componets should be removed and cleaned to keep them functioning:

How to Do So

Clogs/Jams

- Do these happen, if so what to do (fatbergs are becoming a major problem in conventional WWT, will this occur here as well?, also sludge/biofilm plugs?)

Sludge Removal

- This could be done via an auger perhaps

- If not this may eventually need to be done due to undigestible solid buildup

Internal Links

- Anaerobic Digestion

- Biogas Upgrader

- Gasholder

- Lucky Hill Farms

- Seed Eco-Home

- Aquaponic Greenhouse

- Waterless Urinal

- Black Water

- Artificial Wetlands

- Greywater Garden