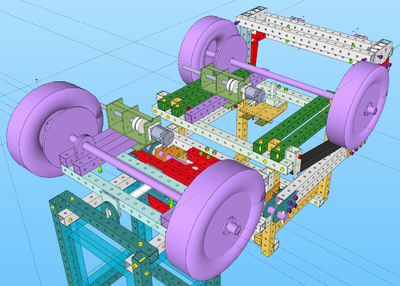

Bulldozer Geardown

Design Proposals

single reduction with full axel

Day 1 - Dorkmo

- Folder of first draft Sketchup Files - [1]

Design Review

Further Conceptual Design

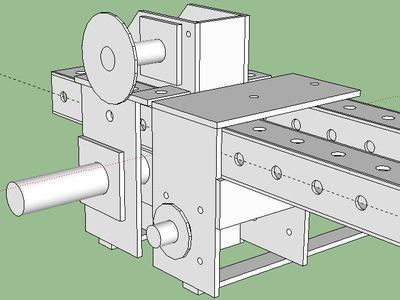

Geardown Iteration Day 2 by Dorkmo

Further Iteration

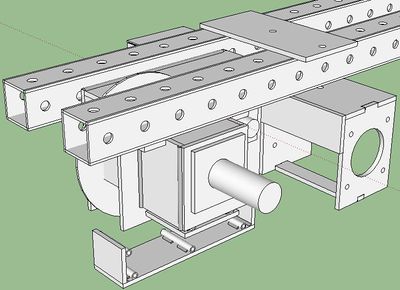

Review of Day 2 by MJ

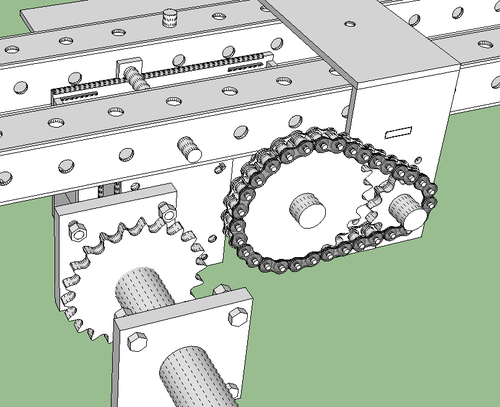

It turns out that the sprocket sizes make the geardown particularly large. So I am looking at Page 82 of Martin Sprocket Catalogue and see that the smallest 100 pitch sprocket that would fit our needs is 10 teeth, Diameter of 4.6". This would give us 25 teeth, Diameter of 10.7", as a possibility - but better yet - go for 3x the reduction - 10 teeth to 30 teeth. If 36 teeth is 15" diameter, 30 teeth is about 13" diameter. So inside the geardown unit, we'd need 2x reduction - or going from 10 to 20 teeth - or 8.6" OD. Thus, a 10" box (1/2" walls) appears to suffice for the geardown unit.

Thus, make first step 3x reduction, and second step 2x reduction- to get the geardown unit to compact size of 10" width. The height would need to extend to whatever geometry would make this fit possible.

We would have to get decent prices on the hubs from whatever source is best. We could compromise to 2.6 reduction for the first step if we use this 26T sprocket and weld our own hub.

proto type 1

Mount based on quick attach module

Chain cover and oil pan

- 4 parts to cut

- top in

- 2 holes to mount to frame and standoffs

- holes to accomidate both flanges' bolts if necessary

- larger holes around shafts to accomidate bearings

- bottom in

- holes to accomidate both flanges' bolts if necessary

- larger holes around shafts to accomidate bearings

- top out

- hole for shaft

- bottom out

- hote for shaft

- top in

Mount DXFs

Initial Conceptual Design

Design Conditions of Satisfaction

Uses exising Quick Connect Wheel rotor - its shaft output.

Uses exising Quick Connect Wheel rotor - its shaft output. Geardown module is CNC cut from 1/2" steel sheet

Geardown module is CNC cut from 1/2" steel sheet- Notches are made such that the structure can be assembled only one way

- Mechanism for quick disassembly is included

- Mechanism for tensioning the chain drive is included

- Enclosure allows easy replacement of parts

Quick attachment of wheel onto the output shaft of geardown module is possible

Quick attachment of wheel onto the output shaft of geardown module is possible- Wheel is secured via a keyway

- Input shaft is 1-7/8" thick, output shaft is 3" thick

- Standard cold rolled shaft is used

- Mechanism for retaining axial thrust is included

Geometry must line up for the connection to Quick Attach Wheel

Geometry must line up for the connection to Quick Attach Wheel Guards protect any exposed chains/sprockets for safety

Guards protect any exposed chains/sprockets for safety Method of coupling to existing Quick Connect Wheel must be used - via chain drive - while considering geometry of frame a drive components

Method of coupling to existing Quick Connect Wheel must be used - via chain drive - while considering geometry of frame a drive components- Quick Connect Wheel and Geardown units must be sufficiently stable to maintain chain tension. Tightening mechanism must lock in place.

Reference must be provided to verify existence of off-shelf parts

Reference must be provided to verify existence of off-shelf parts 100 Pitch Chain must be used.

100 Pitch Chain must be used. Concept must show approximate dimensions (+/- 2") of the geardown structure

Concept must show approximate dimensions (+/- 2") of the geardown structure- Geardown unit must be no more than 250 lbs in weight

LifeTrac Existing Design

- LifeTrac - LifeTrac_III frame documentation

- Quick Connect Wheels - shows dimensions

Parts

Preliminary BOM

| Qty | Part# | Source | Description | Unit price |

|---|---|---|---|---|

| 2 | 1-215-47-4-C | Surplus Center | 2-15/16" four bolt flange bearing | $60.95 |

| 2 | 1-210-32-4-C | Surplus Center | 2" four bolt flange bearing | $21.95 |

| 1 | 2 GKS-1045-18 | Grainger | 2" keyed shaft | $72.25 |

| 1 | totally belted | 2-15/16" X 30" shaft | $163.64 | |

| 1 | 100SDS11H | amazon | 11T QD-SDS | $85.17 |

| 1 | SDS178 | grainger | 1-7/8" QD-SDS | $27.25 |

| 1 | 100BS25-2 | mro supply | 25T, 2" bore | $121.60 |

| 1 | 100BS11-2 | mro supply | 11T, 2" bore | $64.00 |

| 1 | 100BS22-2-15/16 | mro supply | 22T, 2-15/16" bore | $113.27 |

| 8 | 21835 | fastenal | 5/8" x 2-1/4" carriage bolt | $1.75 |

for design #5 [3]

Sprockets

Notes: practical limit for 100 pitch ~ 36 teeth - or 15" OD - [4]

80#

- 1-7/8" bore 20T - [9]

- 1-7/8" bore 14T - [10]

- 1-7/8" bore 13T 2.3285" O.R. - [11]

- 2" bore 13T - [12]

- 2" bore 22T 3.79" O.R. - [13]

80-3

- 80-3 sprocket 12T [14]

- stock 1” bore

- cutable to 1-7/8”

- smallest 80-3 sprocket for 1-7/8

- stock 1” bore

- 60T or 68T tooth available 1:5 or 1:5.6 [15]

- stock 1-1/2

- cutable up to 4-1/4

- QD-F

- stock 1-1/2

100#

- 2" bore dia, 11T, 2.504" O.R. - [19]

- 26 tooth - OD 11" - $10 - Surpluscenter - [20]

- 2517 2. tapered bushing [21]

- 2.938" bore dia, 16T - $123 - [22]

- 2.938" bore dia, 25T, 5.3225" O.R. - [23]

- 2" bore dia, 25T - [24]

- 36T 3020 taper bushing [25]

- 3020 3. bushing [26]

- 11T, 2" bore - $64 [27]

- 22T, 2-15/16" bore - $133 [28]

- 25T, 2" bore - $122 [29]

- 60T, borable - $306 [30]

- 60T, taper bushed 3020 - $350 [31] [32]

tapered bushing sets

1-7/8" shaft to 13T 100# sprocket

- keyed 1-7/8" to 2012 size tapered bushing

- 2012 tapered bore, 13T, 2.9105" O.R.

QD bushing sets

- 26T, QD-E

- 1-7/8" to QD-E

Weld to hub

- http://www.triplerinc.com/sprockets.htm

- http://www.voodoosprockets.com/weld-able-hubs--sprockets-y-series.html

- [37]

- http://www.baumhydraulics.com/product.php?productid=27467&cat=0&page=1

- 10T

- weldable hubs

Modeling

- OpenSCAD sprocket designer [38]

how to draw with sketchup [39]

sprockets

45T 100# File:45T.dxf

45T 100# HD File:45THD.dxf

- 1.656836 ftsq

- 11/16 plate steel = .6875

- nominal sprocket thickness .692

- 46.5lbs at 28.05 density

Sourcing Problems

- 100# chain sprokets hard to find

- 80# chain sprokets with bore dia above 2" hard to find

- minimum teeth on 100# sprocket for 3" shaft with 3020 tapered bushing = 28

- max shaft size for a bored to size 100# sprocket = 2.938

- available carriage bolt sizes limited:

- 1/4, 5/16, 3/8, 7/16, 1/2, 5/8, 3/4

- M5 M6 M8 M10 M12 M16

- 1-7/8" QD-SDS torque rating is 5,000lbs

budgeting

- 100-1 sprockets cheaper than 80-3

Links

- LifeTrac Gear Module

- chain cutting tools

- roller chain joining