Charcoal Fuels Workflow

Jump to navigation

Jump to search

Basics

- This page shows how Biomass turns into Charcoal (Both in the "Raw" sense, and potentially more "refined" forms such as pellets/standard dimention "briquettes" etc) in various workflows

- The main focuses on workflows optimized for high quality products (Via washing to produce as pure of carbon as possible, and making more standardized dimentions of material (via Powderization , Pellitization , and potentially conversion into a Slurry ), and efficiency via Energy Recovery (Mainly utilization of Syngas and/or Pyrolysis Oil to reduce heating fuel needs, and Heat Exchangers for thermal recovery)

- This is not for use as Activated Carbon , for that see the Activated Carbon Workflow

- For more intensive research on how the Post-Pyrolysis Washing, or other Char Washing+Processing could be done to produce Ultra Pure Charcoal Fuel and/or Activated Carbon , see Coal Upgrading for now

Workflows

Basic Workflow

- Biomass->Kiln->Charcoal Out

- With potential storage between steps

- Biomass can be peletized, but for a very basic workflow this will most likely not be needed, unless using fuel crops such as grasses etc that will not form "chunky" charcoal like wood etc would

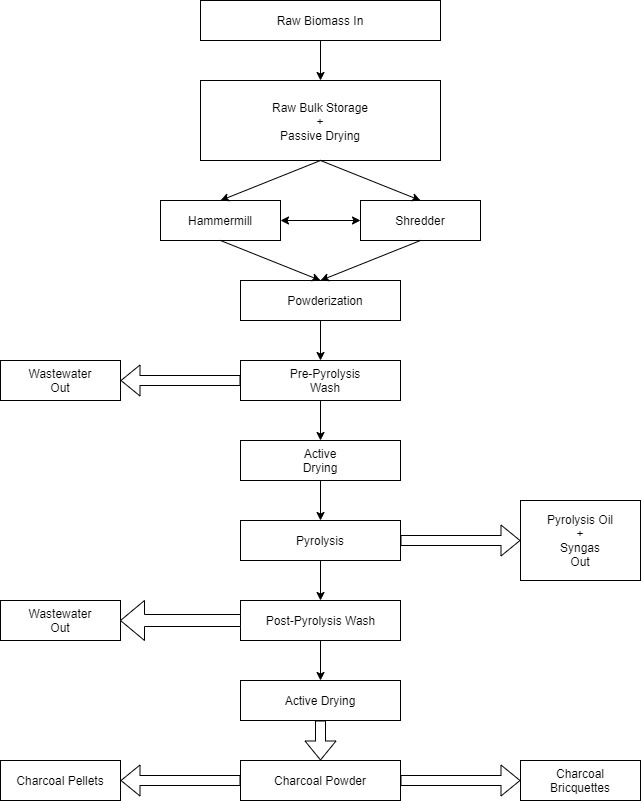

Advanced Workflow

- This is designed to produce the best product, extract as many useful products as possible, and mainly be used in makerspace level and up

Flowchart

Feedstocks

Products

Waste Products

- Wastewater Containing

- Alkali metals

- Misc Minerals

- ?

Disposal Workflows

Internal Links

External Links

- On Staged Pyrolysis THEN Gassification

- "Study of the Effect of Coal Type and Particle Size on Char–CO2 Gasification via Gas Analysis" (use to determine optimum particle size?)