Chris Caswell Log

Time Log

Mar 23 - Mar 29

COVID Response

- Doorhook.PNG

Short useful print, "door hook" for opening public doors or around the office.

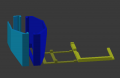

- N95 Mask.PNG

N95 mask, made for combo of 3DP & vacuum form, hopefully a design that can scale

Mar 14 - Mar 20

STEAM CAMP

Mar 9 - Mar 13

Mar 2 - Mar 8

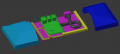

translating blender sketch into FreeCAD (files on Part_Library_for_the_Raspberry_Pi_Tablet).

offshoot from another project here at the shop - 3d printed timing belt, working on the geometry and then will try the varieties of TPU we have here. openscad: File:Timing belts.zip

Feb 24 - Mar 1

- Eco filament experiments: recycled PP & PET from Robries (Surabaya) -> wallet. It will extrude on D3D but bed adhesion issues; heat bed and chamber will be needed, although with perf plate I believe thin wall geometries will be OK.

Feb 10 - Feb 16 2020 --- STEAM camp 1

- Seed for Useful_3D_Prints#D3D_Universal_Calibration_Prints

- prepping for Arduino curric - hello world code (potentiometer -> flashing light & tone generator)

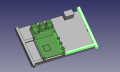

- Printing Jeremy's work in progress for pitab on 1.2mm nozzle

Jan 25 - Feb 2 2020 --- STEAM camp 1

Next time

- Better asynchronous communication and coordination, especially for the remote folks, for the collaborative presence to be felt

- Ideally something embedded in the Wiki, so it will stay on the same platform

- Embedded IRC?

- Meeting time to middle of the day

- Curriculum content (lecture section) better to have posted as video link rather than live stream

- Need project manager role, someone to focus on coordinating documentation, managing remote folks, checking in on anyone falling behind

- Printer @1.2mm -> Plotter -> CNC mill toward circuit -> 0.6mm finer prints (printer will get more and more tuned in as the camp goes on)

- Printing from Useful Print library, which will both produce useful goods showing the value, good calibration prints for the machine, and a good development queue for FreeCAD lessons and practice.

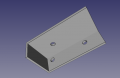

- PiTab case needs to get to a steady, stable state; simple no frills enclosure. Ideally it will have nut catches or some other attachment point, so next STEAM camp can iterate on some external modules.

RPi Software

Based on the NOOBS install: https://www.raspberrypi.org/downloads/noobs/

Used the offline installer package on a FAT formatted 32gb micro SD

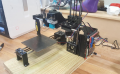

Cura

I had issues trying to run Cura on the Raspbian, it kept crashing. It seems like someone has compiled a version and posted it in the ultimaker forums that will run on the RPi processor: https://community.ultimaker.com/topic/28746-experimental-cura-build-for-raspberry-pi-4-now-available/

Downloads: https://www.dropbox.com/sh/s43vqzmi4d2bqe2/AAADdYdSu9iwcKa0Knqgurm4a?dl=0

Install procedure:

Once the appimage file is downloaded (I used Cura-mb-master-armhf-20191209.AppImage), make the file executable

> chmod +x Cura-mb-master-armhf-20191209.AppImage

Then you just need to run the app image file:

> ./Cura-mb-master-armhf-20191209.AppImage

Camera

From https://projects.raspberrypi.org/en/projects/getting-started-with-picamera/3

Once it's plugged in, Camera just needs to be toggled on in the config -> "interfaces"

Once restarted, you can take a picture like this:

> raspistill -o Desktop/image.jpg

This will activate the camera module and show a view finder, until you hit "Enter" and it saves a picture to the specified location.

Photo updates, newest first

plotting of the arduino circuit from Pieter log -- following along with Belgium

Good gcode visualizer: https://ncviewer.com/ - seems to struggle with big 3d print gcodes, but very quick and easy with the plotting and routing experiments, runs in the browser and just drag and drop gcode file

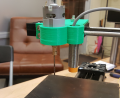

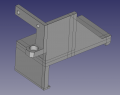

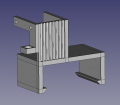

Router Toolhead for D3D, for 555 motor -File:RouterToolhead.FCStd - Fit is close on our D3D with standard settings - not sure if the motor needs to be more secure

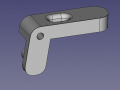

Xiong's Screw Driver - File:ScrewDriver.FCStd - File:ScrewDriver.stl - fits standard 1/4" screwdriver bits

Spiral linear bearing - uploaded openscad code, stl is too big. unzip and compile -File:SpiralLinearBearing.zip - One full set has been printed and is installed on a D3D here to be tested

Thur Dec 9 - 13, 2019

I'm working on replicating the D3D Simple build we worked on in November, recreating it here alongside Marcin's recent changes.

Thur Nov 21, 2019

I have used a belt sander to keep a good sharp bevel

Mon Nov 19, 2019

- OSE wallet File:Ose wallet.zip

- OpenSCAD-ready vector version of the logo - get File:ose_logo_for_openscad.svg

- Iframe of svg, since SVG is not appearing:

Mon Nov 18, 2019

- Top cover for power meter box - File:GasCover.stl

Nov 14

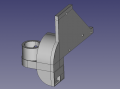

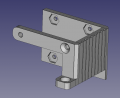

- CC simple extruder.png

Simple Extruder work in progress https://github.com/3DCentral/OSE/blob/master/SimpleExtruder.FCStd

Extruder motor bracket - FreeCAD -File:ExtruderMotorBracket.FCStd

Extruder Active Cooling and Sensor Mount File:ExtruderActiveCoolingAndSensor.FCStd

Spring tensioner - FreeCAD -File:SpringTensioner.FCStd

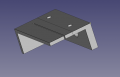

Jig to cut the heat sink - FreeCAD -File:HeaterBlockJig.FCStd

Nov 1 - Nov 7

Work on Simple Extruder -- Cut/drill/tapped aluminum heat sink block. FreeCADed a jig for alignment (also WIP) - I think the same could be done with heater block.

I bought packs of all the hardware for the universal axis build hoping that I could use the same screws for this - but I am not sure this will be possible.

Spring tensioner needs still most work, the bearing from that is pictured is obviously not going to work...

I have come around to horizontal tool mount; I do feel like it will be more compact and stable. I think could be as simple as 3 holes and wing nuts.. focusing on full functioning of simple extruder first.

Edit: Nov 8 -- updated version of spring tensioner and extruder motor bracket

Extruder motor bracket - FreeCAD -File:ExtruderMotorBracket.FCStd

Spring tensioner - FreeCAD -File:SpringTensioner.FCStd

Jig to cut the heat sink - FreeCAD -File:HeaterBlockJig.FCStd

Oct 25 - Oct 31

After pulling many a hair out trying to make modifications to existing carriage file (every version I could find), have given up and began to just re-CAD from scratch. As proof of concept, made universal tool mount mods to carriage in Blender, but as a back-up I'm doing a super simplified mechanism as well in FreeCAD.

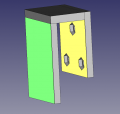

For Simple Extruder, I also started from scratch to build a replacement for the extruder spring base bracket that will also include wire org for the quick attach wiring, and a place for the toolhead mount. This should work for vertical or horizontal mounting, whatever we decide. . Also got trip details planned and tickets purchased for Nov 8 - 23

Simple Extruder Spring Base Bracket, Wire org and toolhead mount - FreeCAD -File:ExtruderMotorBracket.FCStd

Simple Mount Option - size:nullkb - FreeCAD -File:SimpleMount cc312019.FCStd

Quick swap mount - STL-File:Cc dev uta mount 31OCT2019.stl

Oct 20 - Oct 24

Working on Simple Extruder and Universal Toolhead Mount. Note also that D3D_Simple#Part_Library has more.

Simple Extruder Spring Base Bracket - size:nullkb - FreeCAD -File:Simpleextruderspringbasebracket chriscommit.fcstd

Universal Toolhead Attachment - size:nullkb - FreeCAD -code

Working through FreeCAD - Export issue - even trying to compile from the base files I pulled from this - Universal_CNC_Axis#Universal_Axis_-_Working_Document. FreeCAD file - File:D3D Universal Carriage v1910.fcstd

Tue Oct 9, 2019

Sat Sep 14, 2019

First Conversation with Marcin

- Runs 3D Central - http://www.3dcentralva.com/

- He and Bro doing it.

- https://certification.oshwa.org/us000038.html

- https://www.thingiverse.com/thing:674179

- https://opensource.com/article/19/6/hardware-music

- https://www.thingiverse.com/thing:242087 - the source with parts

- Everything about new skills, fundamental change in economy - supply chain, production. Local production.

- Microfactory concept - manufacturing locally. Technologically - close - socially - far.

- "Waste and drag of intellectual property. And Competitive Waste"

- 3D Brooklyn -

- E-nable - build a hand - http://enablingthefuture.org/upper-limb-prosthetics/

- https://www.youtube.com/channel/UCxkd2FJltPA2vwofdKxn-cw

- OS culture - 10

- Printed Solid - another guy in Delaware - Matt Gorton - quit Printed Solid.

- Hackerspace down the street -

- Technical and social, but also economic -

- Environmental - climate change - from inefficient production.

About

- Founder of 3D Central - http://www.3dcentralva.com/

- Currently working on developing the STEAM_Camp_Team