D3D v18.12

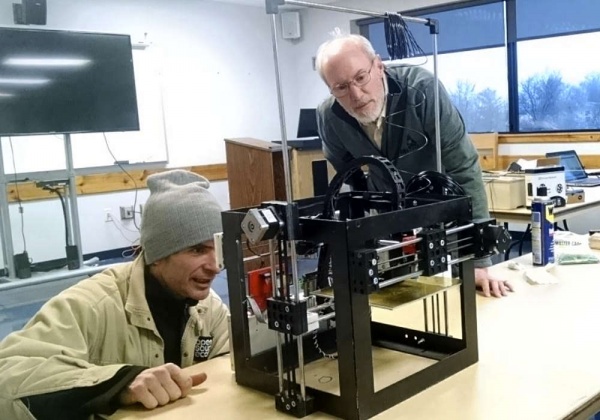

Build at Highland County Community College

Introduction

- v18.12 is same as v18.10 in 3D Printer Genealogy except that we used a modified Lulzbot Mini omnidirectional fan shroud for print cooling

Build at Highland Community College

- Feb 11, 2019

- Used 13" frame with 1" symmetric extension consisting of half idler pieces under the Universal Axis

- Titan Aero 3mm extruder, using 1.75 mm filament without problem

- Y axis pretested with 300 mm/sec motion

Extruder

Extruder CAD

Stock Titan Aero mount bracket. See [4]. Bracket - [5] - STEP + STL. Check out drawings from E3D - [6]. STEP of Bracket - File:Bracket.fcstd

Titan Aero with motor - [7]

Titan Aero mount top plate. File:Brackettop.fcstd.

Simplified carriage: File:Universal axis carriage side.fcstd. (From D3D Part Library)

Sensor holder. Print at 100%. File:Sensholder.fcstd. File:Sensholder.stl.

Lulzbot Mini 2 OSE Mod Fan Shroud. File:Lulzbotmini2shroud.fcstd. Original source file with sketches from Lulzbot- [8]. STL - File:Fanshroud.stl.

Lulzbot Mini 2 Extruder [9].

CAD of Parts

Manual

See 3D Printer Manual. Note that the manual covers up to the Titan Aero extruder - but it does not cover the new omnidirectional fan shroud that we borrowed from the Lulzbot Mini 2 friendly 3D printer.

Code

- Lulzbot Cura settings file - File:D3D 14inchframe Titan Aero Omni Shroud 04 175.ini

- Use File:Marlin v1810.zip - works as is

![Underslung Extruder Base without fan and shroud - [1]. With fan and shroud - [2]. Ready for printing - [3]](/images/thumb/5/5d/Extruderassy.png/120px-Extruderassy.png)

![Stock Titan Aero mount bracket. See [4]. Bracket - [5] - STEP + STL. Check out drawings from E3D - [6]. STEP of Bracket - File:Bracket.fcstd](/images/thumb/5/51/Titanstockholder.jpg/120px-Titanstockholder.jpg)

![Titan Aero with motor - [7]](/images/thumb/7/78/Titanwithmotor.png/120px-Titanwithmotor.png)

![Lulzbot Mini 2 OSE Mod Fan Shroud. File:Lulzbotmini2shroud.fcstd. Original source file with sketches from Lulzbot- [8]. STL - File:Fanshroud.stl.](/images/thumb/c/c2/AAAAAAAAAAAAA.png/120px-AAAAAAAAAAAAA.png)

![Lulzbot Mini 2 Extruder [9].](/images/thumb/d/de/LulzbotMini2Extruder.png/120px-LulzbotMini2Extruder.png)