Polyhydroxyalkanoates

Basics

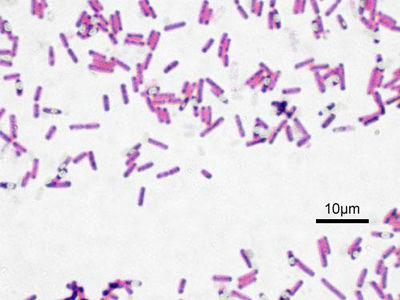

Polyhydroxyalkanoates are linear polyesters produced naturally by bacterial fermentation of sugar or lipids. More than 150 different monomers can be combined within this family to give materials with extremely different properties. These plastics are biodegradeable and are used in the production of bioplastics. Polyhydroxyalkanoate polymers are thermoplastic, can be processed on conventional processing equipment, and are, depending on their composition, ductile and more or less elastic.

Carbon Sources: Carbohydrates (molasses, sucrose, starch, lactose from whey, cellulose hydrolysates), alcohols (glycerol, methanol), fats and oils, organic acids.

Applications: packaging and coatings, hygienic articles, fibers, adhesives, carriers of flavoring substances in foods, biodegradable fishing nets, etc. Also various medical applications (e.g. implant materials, suture materials, controlled release of active principles).

Polyhydroxybutyrate

Polyhydroxybutyrate is the most common form of PHA currently under research and development. The type of polymers is dependent on the microbial synthases in the host organism. An advantage of PHB over other bioplastic production routes is the direct generation of a polymer, versus other routes which produce a substrate requiring chemical synthesis to a polymer.

Chassis organisms

Biosynthetic genes