User:Dorkmo/Log/2013

dec 11, 2013

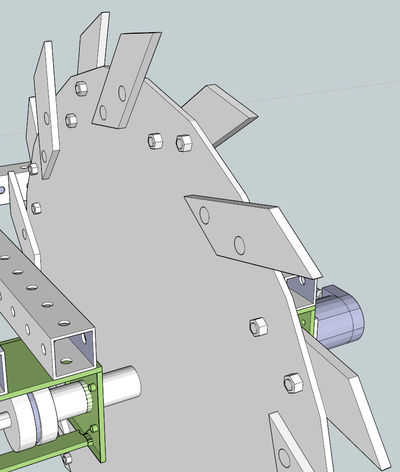

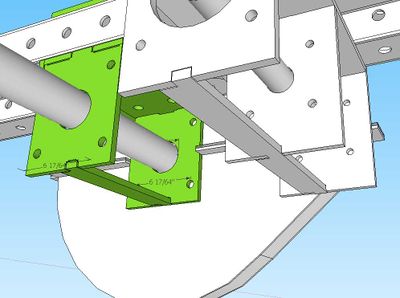

sketched- added square tube across top of main lifetrac arms to mount 2 cylinders on doc

dec 9, 2013

sketched- added the new cyclinders and sketch new mount for lifetrac arms google doc

dec 3, 2013

did a little idea for mounting trencher on lifetrac Media:Trencheridea20131203.torrent

started an idea for the MicroHouse Collaboration 2014. half circle ceb design. roof will slant to center of flat wall. google doc skp - work in progress

nov 5, 2013

machine screw idea for trencher 1-1/2 long. 1/2" nuts are a little less than 1/2 tall, wich will be shorter than the 1/2 thick tooth plate.

could use 3/4" plate for teeth in order to use 3/4" bolts

Media:Trenchermachinescrews20131105.skp

oct 8, 2013

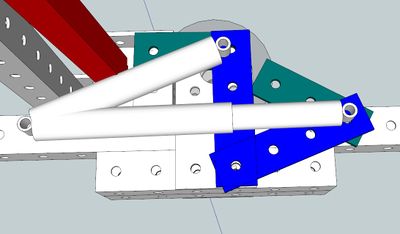

backhoe side to side pivot with scissor File:Backhoe sidebyside8.skp

oct 6, 2013

did backhoe sketch File:Backhoe sidebyside2.skp

Thu Sep 18, 2013

Design Proposals

Cab

Arm mounting shaft split.

sep 16, 2013

finished cutting tubing

cleaned up some pivot plates with chisel and file

sep 15, 2013

finished 4x4s

cut DOM tubing for pivot plates

tools used:

- band saw

- speed square

- C clamps

- angle iron

- calipers

- steel shims

process description:

- set up an end stop on the band saw

- clamped small piece of angle iron 1/2" away from blade

- used speed square to keep perpindicular

- placed some shims to keep area infront of angle iron level with band saw base

- used some extra tubing with same O.D. to maintain distance of the swivel clamp by placing on opposite side of clamp

- placed tubing to be cut in clamp

- lowered blade to just above tube

- using calipers checked distance

- tightened clamp

- cut

- maintained about 2-3.5 on the hydraulic lowering setting for the kalamazoo brand band saw

- after cut checked width for accuracy

- continued next cut

- durring cutting used file to clean up edges of previously cut tube ring

- set aside for next process

sep 14, 2013

cut day 4x4s

tools used:

- speed square

- tape measure

- ruler

- soap stone

- abrasive saw

- big table

- scrap metal for leveling

- power cord

process desription:

- set up cutting area for 10' sections

- marked general location of cut on 4x4

- using ruler found center between holes

- marked center

- used speed square to draw line along center

- checked line with ruler again

- aligned in saw

- tightened into saw

- algined again

- final tighten

- cut

- when abrasive wheel became smaller would rotate 4x4 so that saw would continue previous cut

- marked feet and inches on 4x4

- placed in pile

sep 13, 2013

pivot plate

seat

sep 12, 2013

cleaned up the workshop a little bit

tweaked a few things on the vw sled

- the lever for the clutch will interfere with current design, need to change something

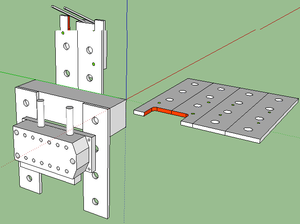

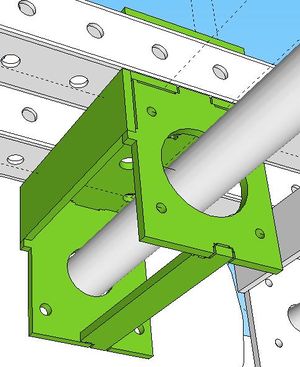

sketched a pivot for the lifetrac6 to be mounted above the top pivot point

sep 11, 2013

- shifted in back instead of lowering it down

- added tanks above pump

- flipped around

possible double pump [1]

- picture of holes on engine http://www.huelsmann.us/bugman/FilterTech.html

- looks like should be able to tap and use two side holes as mounts

- vw sled utilizing holes on either side of oil pump plate

- moved tanks around

- added radiator

sep 10, 2013

- new sled idea for vw

- angle iron base with vibration mounts front and back

- slides into tractor frame, bolts in 4 corners

- accommodates current exhaust system

- double pump possible

- known issues:

- sticks out the back

- still need to do tanks, should fit above bell and pump

sep 9, 2013

- gary suggested making a angle iron frame that slides into the 4x4 frame

- seems doable, started doing a little brain storming. no model yet.

- swapped some ideas with marcin and lucas about changing a few of the mounting layouts for the arms and pivots

sep 7, 2013

- measured and drew bell housing holes

- used angle iron to attach to bell mount plate

- got rid of extra bell mount plate material.

- realigned pump and 4x4 mount

sep 6, 2013

cleaned up a few things. no changes.

sep 5, 2013

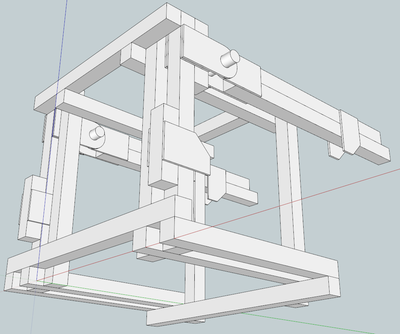

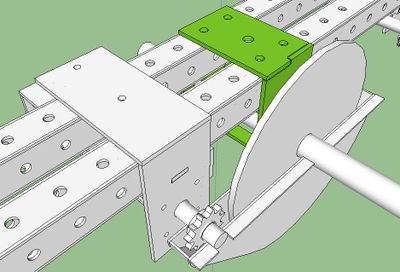

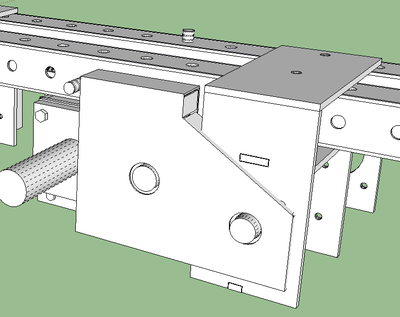

did a pc ws version coupled instead of chained n sprocketed. used a 4x4 tube as pump mount.

sep 4, 2013

proposal for tractor frame change to mount 4x4 frame on back end.

aug 29, 2013

video of vw mount http://www.youtube.com/watch?v=Pr0UhhC7XpQ

added two angle irons for support on opposite side. may be welded or bolted together.

aug 16, 2013

going out of town. my sketchup work will be on pause.

https://docs.google.com/file/d/0BwxMMqGvwTM-VUJ1azU1aXEzRlU/edit?usp=sharing

- started hose routing

- 1-1/2" suction hose has 5" bend radius

- will need to use pressure line with a 45 degree elbow connecting to pump. straight out wont work.

- added rough position of cooler and filter

- bolt conflict with the horizontal and vertical pivot mounts located on the lower front 4x4

- can see a little here video

- cleaned up OSE Torrent Files page a little

aug 15, 2013

https://docs.google.com/file/d/0BwxMMqGvwTM-RWo5MDhoMVZJSVk/edit?usp=sharing

- added some pipe fittings

- had to trim motor mount

- rough idea for hub to mount motorcycle sproket

- sourced and sketched some Vibration Isolation Mounts Cylindrical Type

- need to move a few things around slightly

- not sure how to get nut on within 4x4

- still need cooler and filter etc

aug 14, 2013

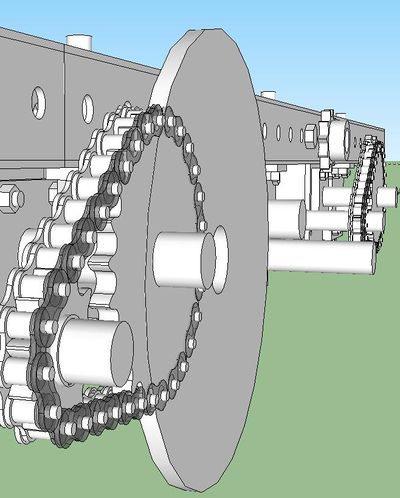

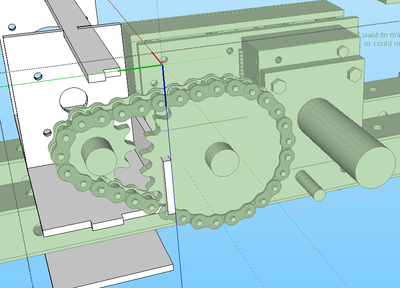

- added chain and sprocket idea

- added hydraulic pump model

- need to get bolt pattern measurements of bell housing

- need to add hose and cooler models

aug 13, 2013

http://opensourceecology.org/wiki/File:LifeTrac6_(dave)(dorkmo)4.skp.torrent

4x4 XYZ frame for mounting VW engine.

http://opensourceecology.org/wiki/Power_Cube_WS#WS.2B

july 30, 2013

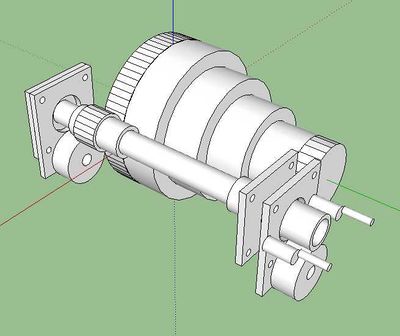

http://opensourceecology.org/wiki/File:Geardownaxel5.skp.torrent

utilizing steering pivot allows for front and rear drive axles. this theoretically simplifies a geardown. could also allow for simple gear changing by moving motors and other adjustments.

http://opensourceecology.org/wiki/Bulldozer_Geardown

jun 24, 2013

Sun Jun 23, 2013

The Control Cab Control Panel needs accommodation of:

- Power connection to Power Cube (3/4") - up to 4 Power Cubeconnections - let's do this.

- Case drain to Power Cube (1/4") - need to do 4 pairs if using 4 Power Cubes independently.

- 6-spool backhoe valve - 1/2"

- 2-spool motor valve - 3/4"

- 2-spool foot pedals - 3/4"

- Totals

- [8] pairs of 3/4"

- [6] pairs of 1/2"

- [4] singles of 1/4" (just return)

File:HydraulicQAcabmanifold10intermediateuntitled.dxf

Sat Jun 22, 2013

Control panel for hydraulics:

working with chris on hose routing for trac

- 8 – ¾

- 20 – ½

- 1 male twords power cube

- valve bolt mounts to 4x4

- File:HydraulicQAcabmanifold6intermediate2B.dxf

- File:HydraulicQAcabmanifold6intermediate2A.dxf

Friday 21, 2013

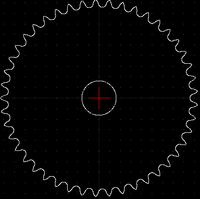

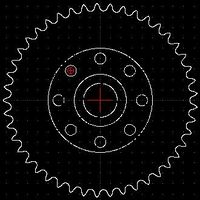

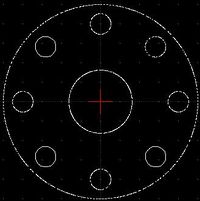

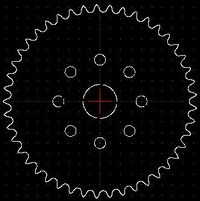

Sprocket Design

See also Chain Length Calculator.

Resulting Sprockets

Sprocket with hub:

Use this for cutting. This is just the hub backing plate:

Now the actual sprocket for cutting:

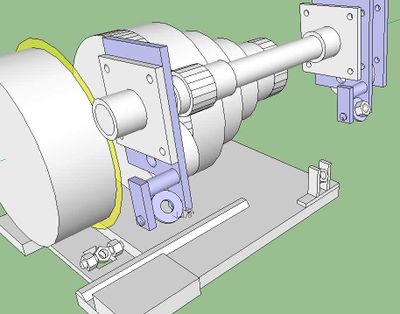

Lathe Work

possible motor for lathe surplus center

doing a draft with motor mount and threaded rods that tighten to base with some pieces that can c-clamp to base.

Thursday 20, 2013

drew a rough sketchup of the lathe. going to redo motor mount. File:Lathe1.skp

found this sprocket openscad thing on thingiverse http://www.thingiverse.com/thing:7918

Tue Jun 18, 2013

Download DXFs of the 6 parts here - these are 6.26 bolt spacing for these bearings - and DXFs have been corrected for 3/4" bolt holes, meaning 3/4" + 1/16" for CNC torch allowance. File:GeardownDXF.zip

- went back to the basics and cut out intermedate shaft and using a quick attach module style mount.

- requires very large sprocket to achieve desired ratio

- need to change chain cover to accomidate flange bearing bolts sticking through.

DXF Files of Component Plates for Simple Geardown

Sat Jun 15, 2013

See also Geardown Concept. Download folder of Sketchup files- [2]

added some detail

- bolts for flange bearings

- had to shift some things around to account for tighter space

- added QD bushing for 1-7/8

- changed a couple mounting bolts to frame

June 8, 2013

Needs discussion of how size can be made more compact.

https://docs.google.com/file/d/0BwxMMqGvwTM-RjJxVGNUVm90aVU/edit?usp=sharing

added to the model a mount style with QA facing opposite direction from before

- shortened distance the 2-15/16 bearing hangs out

cleaned up some of the mounting and case holes

- not sure about where the best places are to have mount holes

June 7, 2013

https://docs.google.com/file/d/0BwxMMqGvwTM-N1piZlVIaGtqUXc/edit?usp=sharing

started modeling the chain and sprockets.

- looking for collisions

- taking up as much slack of chain in design as possible

June 1, 2013

Design Sprint - Dozer Geardown

01/13

preparing to make a chicken coop and a raised bed.

- thinking might do a mashup of these two coop designs: http://sketchup.google.com/3dwarehouse/details?mid=5b2fbd27cfb5a48e6654971052d2f27e http://sketchup.google.com/3dwarehouse/details?mid=11bfd7bd9f6b256493bc835096fe177a&prevstart=0

- done a couple https://docs.google.com/folder/d/0BwxMMqGvwTM-R3lETnFYQXJZckk/edit

- thinking about spinning door. small dc motor. hall effects sensor. arduino? one door to chicken run, one for yard.