User:Dorkmo/Log/2015

october 2015

built another battery prototype. still having trouble storing a charge. looking at the voltage graph of the charge it looks like it is charging, but when i try to drain the battery it dies within seconds. im not sure, but im guessing that part of the chemical reaction is happening but not all. Nickel-Iron_Battery/Chemistry

next steps. going to mix graphite into the iron. going to try some different charging procedures.

august 21, 2015

at FeF helping with the dozer build.

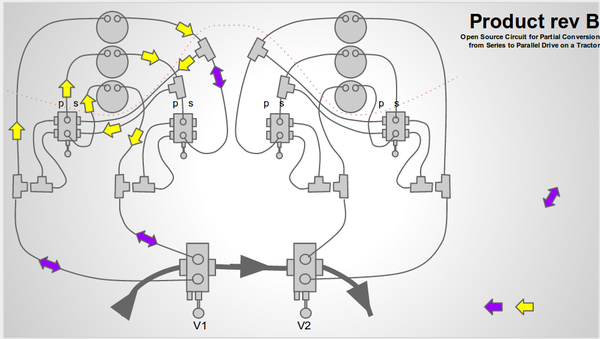

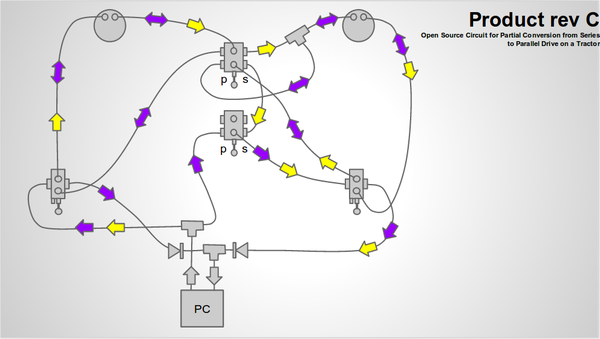

drew up some design ideas for hydraulic systems for switching between parallel and serial circuits between motors.

august 18, 2015

another mount for the cab

https://3dwarehouse.sketchup.com/model.html?id=u1fa644ad-f1d7-4c55-8436-72f85667c65f

august 16, 2015

sketched some rough ideas for cab mount. used some of the dimensions from LifeTrac 6

https://3dwarehouse.sketchup.com/model.html?id=u5e9808b8-8003-4d74-af5d-357a4f2b847b

august 11, 2015

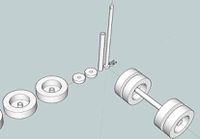

tried some different mounting ideas for the backhoe pivot

https://3dwarehouse.sketchup.com/model.html?id=u76cbbefd-28e0-4e72-ae5d-48e0c683dd8c

Added comment on tanks and bolt fit - Talk:Power_Cube_v15.6#tanks

august 9, 2015

getting ready to retrofit previous backhoe design onto new bulldozer work.

- Backhoe_3/Pivot_Range_of_Motion_Calculations

- video of operation youtube

- Cory_Shenk's_Log#Backhoe

- smart mob work

notes:

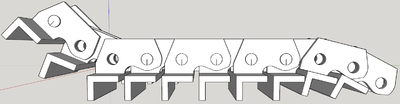

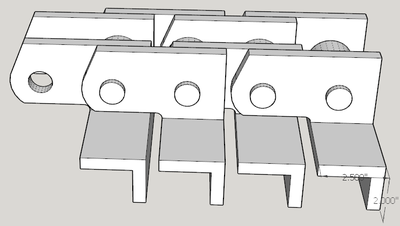

- goal to use same chain links from other parts

- microtrac chain sections difficult to fit between mount structure and 3" pivot pin

made a sketchup model attempting to put chain around existing pivot pin. was only able to get a total 100 degree range of motion. to get full 180 degrees will have to extend the pivot pin above/above main mount, or make changes to structure.

https://3dwarehouse.sketchup.com/model.html?id=uaf6bb9c4-99da-42b8-b9a5-980cfde30f0d

https://3dwarehouse.sketchup.com/model.html?id=uaf6bb9c4-99da-42b8-b9a5-980cfde30f0d

to use the stock track chain with 3x8 cylinders, the system will need to be mounted below the pivot mount

august 4, 2015

bulldozer idea

https://3dwarehouse.sketchup.com/model.html?id=u966d9813-c950-4328-8f36-b6ff29af62c4

august 2, 2015

quick attach

removed one of the 4x4s on the quick attach mount.

I

https://3dwarehouse.sketchup.com/model.html?id=ue3ff6d4a-759c-4890-9787-26c26e3bfe05

arms

made some more mount ideas for the arms

the puller seems to still have the best performance

https://docs.google.com/spreadsheets/d/1aQeiENk6MHzdeZlHems5LpYl13mHXlYPHkAl5pTcOEc/edit?usp=sharing

M

https://3dwarehouse.sketchup.com/model.html?id=u7618a250-9be6-4ee2-a46e-3f115488ab18

L

https://3dwarehouse.sketchup.com/model.html?id=u16de80f7-630a-483f-901e-be39fe94a344

K

https://3dwarehouse.sketchup.com/model.html?id=udb8d5acb-9917-4870-9af3-0d9ca0973406

J

https://3dwarehouse.sketchup.com/model.html?id=uc64c8997-8db7-494e-b598-b0967cbc0ecf

july 31, 2015

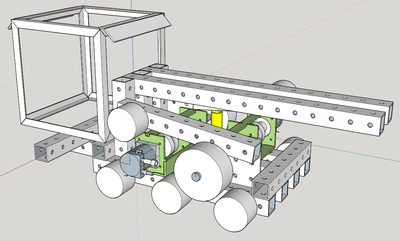

arm syle with cylinders pulling from above

https://3dwarehouse.sketchup.com/model.html?id=u404fa204-5861-4db1-98ca-02c293ad087d

july 15, 2015

mount for forward crylinder

https://3dwarehouse.sketchup.com/model.html?id=ud05ae13a-6142-4ebf-8494-696844150f8f

july 14, 2015

it looks like the full size bobcat standard attachment plate will just about fit the width of microtrac. trying to make it work with arms. still need to make hydraulic cylinder geometry work.

https://3dwarehouse.sketchup.com/model.html?id=u611b96c8-5479-420d-b12e-0acb75b85fc7&uploadsuccess=1

july 13, 2015

https://docs.google.com/spreadsheets/d/1aQeiENk6MHzdeZlHems5LpYl13mHXlYPHkAl5pTcOEc/edit?usp=sharing

started spreadsheet on hydraulic lift capacity. need to do one to approximate tipping weight.

july 12, 2015

T=rFsinθ

- for arm styleH

- r=20.4

- θ=12.2

- F=cylinder?

- Area=?

- psi=?

- 54" from pivot to end of arm

- 72.9 degrees

july 11, 2015

sketched a couple different arm configurations for microtrac

https://3dwarehouse.sketchup.com/model.html?id=u5456c737-4e1c-44a6-a0bb-3599bad7dd35

https://3dwarehouse.sketchup.com/model.html?id=u4fcf4728-0320-4dcf-8053-cde04e3b2b9b

https://3dwarehouse.sketchup.com/model.html?id=u5dc84c10-a2ee-4ddb-a9b7-583d72a61161

https://3dwarehouse.sketchup.com/model.html?id=u001c15f2-4a7f-4e39-b69d-bf048056645f

https://3dwarehouse.sketchup.com/model.html?id=u3b9f6478-0397-44fd-9a16-a832d7a8ebf5

https://3dwarehouse.sketchup.com/model.html?id=u2d908e07-c133-4408-83be-8038bd85f531

https://3dwarehouse.sketchup.com/model.html?id=u62e667a7-870d-4443-bdb1-f5d745a1178b

july 5, 2015

File:Ose-microtrac-tracks-20150705.skp

june 26, 2015

File:Ose-microtracB-20150620.skp

started doing some work on tracks. i think using the style where each sequential track is inner then outer will simplify welding work. will it create problems for sprocket rolling into gap? pinch point?

i think the size of angle iron pads needs to be slightly smaller than pitch between rollers for space between

need to hunt some plugins or converter, cant export sprocket from openscad and import into sketchup

june 23, 2015

For reference, see MicroTrac_2015_Concept

File:Ose-microtracB-20150623.skp

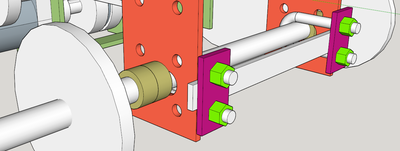

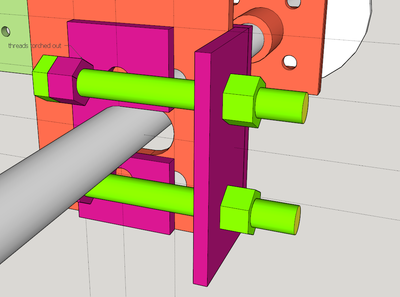

general updates and tweaks to tensioner

june 20, 2015

File:Ose-microtracB-20150620.skp

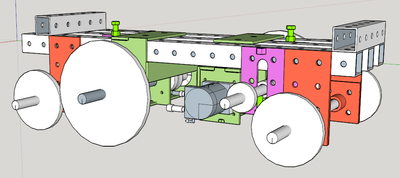

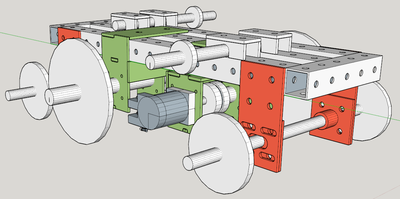

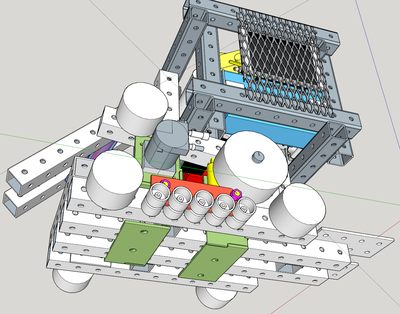

sketched marcin's new layout idea. so far so good.

put tensioner on small idler. might also need to figure out how to tension 12" pully in front of sprocket.

marcin feedback/made some tweaks

feedback marcin/changed the tensioner device

thought the bolt might need to be torched out but on second look i think its alright

may 7, 2015

- added some small rollers.

- might be tricky to keep from getting caught on linkage of treads

- perhaps find plastic/rubber wheels that would less likely catch

- might be tricky to keep from getting caught on linkage of treads

- might make front and back rollers larger diameter

- need more ground clearance

- might move rotor units apart 4 more inches

- longer track length to support more

ose-microtrac-tracks1-20150507-2.skp

TODO:

- find dimensions of standard attachment plate

- design

- revisit other design/mounting options

- sketch model with both motors behind pc

- utilize different length of track

- sketch model with both motors behind pc

- make 3d scale model for printing and testing

april 29, 2015

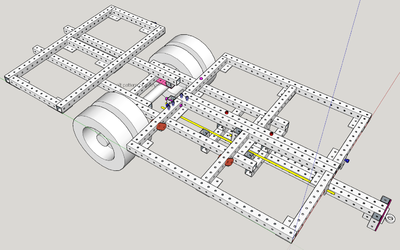

updated File:Ose-trailer-high16-20150428.skp to have a platform attached to axle

began work on microtrac tracks mounting. utilizing existing motor mounts. File:Ose-microtrac-20150429.skp

april 26, 2015

design sprint meeting on MicroTrac_2015

april 23, 2015

Added some more design proposals for trailers

april 22, 2015

tweaked the trailer design a little

april 20, 2015

First draft of trailer axle sketchup model:

File:Print-traileraxel.skp - Trailer Axle at Warehouse (you can zoom and rotate below:

File:Print-traileraxel20150420.stl

To see how these are used to make scale models, go to Lay-Flat_Trailer#Scale_Model_Rapid_Prototyping

april 8,2015

had to order some more drill bits. some of the ones i got were super brittle and broke quick.

think im going to try to build up the portuguese wiki pages. will also use it as an opportunity to test some best practices ideas. i'd like to have a clear table for versions, change log, approx number built, link to file landing page.

- some examples i might incorporate

march 28, 2015

finished cleaning the holes of one side of one cage. i held it flat and poured water evenly over the holes. took about 6 seconds for it to drain through. continuing on.

march 18, 2015

Sign up for osemail on wiki. Will return to dozer gear down.-MJ

i used https://www.3dhubs.com/ to order some larger cages to compare and test out. the local guy that printed them had a very high quality print with ABS, much better than my prints. even with a better print it appears the design as-is requires to have a lot of holes cleaned out.

if battery proves viable, might attempt using a two material 3d print with dissolvable material in holes. or maybe hole design improvement is possible.

in the mean time, going to clear out holes manually and might test larger cages next week.

- design change

- might make the powder area smaller and leave upper part where lid inserts same size.

march 14, 2015

printed two larger cages. tested holes with some food coloring. put a few drops inside, filled sink with water up to top of cage, opened sink drain, able to see color come through holes that are open. it appears more than half of the holes are not open for water to flow through. going to try to get a small drill bit to quickly open up. also considered acetylene torch tip cleaners but i think they might be a fraction too big, and might not be able to cut into.

if the design proves viable, hopefully i could fine tune print settings for more predictable hole success.

http://en.wikipedia.org/wiki/List_of_drill_and_tap_sizes

march 11, 2015

- ordered some nickel powder. readings say edison batteries had nickel flakes layered in the cells.

- going to print new cages double the height.

- might look over the ultra smart charger firmware

- would be nice to tweak some things if its not too difficult

- if it it maxes over 2V lower the mAh's

- disregard internal resistance errors

- does a weird thing where it wants to discharge some before it charges

- would be nice to tweak some things if its not too difficult

need to read more about typical charge scenario

also, found this nifty website to compare text http://text-compare.com/ , i think theres a bug in the cage scad file

march 8, 2015

- discharge data was poor

- voltage reached minimum after 15 seconds

- durring charging the part of the wires coming out of the cages were gassing the electrolyte.

- cages were not charging

it seems that the nickle wires coming out of the cages were alone acting as the electrodes. The resting voltage was around 1.2V which is in the range of what would be expected. i lowered the electrolyte level below the wires and it changed the charge behavior. voltage would max over 2V quickly. In the config I lowered the max charge mA to 1. used the NiCd trick to start charging. I expect the voltage will plateau quickly. will be interested to see if internal resistance changes. will let charge for a day.

march 5, 2015

- hooked up test battery to the ultrasmartcharger.com

- had minimal success, wouldnt recognize as a battery

- it would see it when in battery recovery mode

- but would immediately errorr bc max voltage of 2V around 2.04V

- found the custom configuration utility on their website

- tried to tweak max voltage but even the custom max is 2V

- after a few tests tried lowering the charge currernt to very low

- set to 10

- tricked the charger by tapping a AA NiCd battery on the leads before the charge

- not sure if this actually made a difference but it seemed to help

- running firmware 0.524

- charging continued without error led flashing

after a few hours i pulled the SD card to check the data. the data seems to show that the cell was increasing its voltage. and was indicating it had reached about 25mAh. i assume that is calculated and not truly measured like voltage. in the next couple days i plan to run a full charge, discharge, charge, discharge, charge analysis. i think that will give a true capacity rating.

here are the data for the fist charge attempt google doc

feb 28, 2015

- test charging some standard NiCd batteries to get acquainted with how the charger/analyzer works

jan 31, 2015

- took delivery of the battery charger/analyzer. instructions say the memory card can only be 2gb max.

- need one of these

- need to format to fat16 [1]

- will probably finish cleaning up the groove stuff this week

- might start looking at stepper stuff soonish

jan 3 2015

- cage floats in water, need to constrain

- going to use two inward divots, upper and lower, on narrow sides of cages. will mate with wall outie divots

- add sphere r=caage endwal thickness + divot radius. then subtract divot

- or maybe just make endwall thicker. k.i.s.s.

- going to use two inward divots, upper and lower, on narrow sides of cages. will mate with wall outie divots