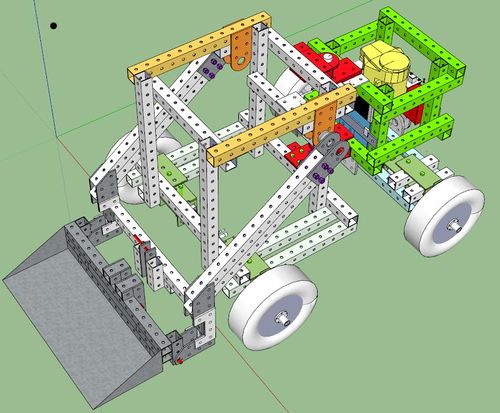

LifeTrac 6

Jump to navigation

Jump to search

| LifeTrac 6 | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews | File:LifeTrac 6.png | |

Overview

2019

In active use.

Previous

Discussions - aka Review

Production Meeting - 9/20

- QA wheel mounts to put on the cab -- they are quite fitting; had to grind the frame & mounts: got two on last night

- Wheel mounts -- holes did not align because we used old material from LFT 5; going to use smaller bolts (7/8" is fine); mounted to power cube, need to complete 2x mounts on cab

- Wheel hubs -- more issues with alignment

- May be able to start on hydraulics today if wheel mounts go smoothly, but planning for hydraulics tomorrow

- Audrey picked up x50 1" washers at Sweiger this morning

- Need to swap out 14 bolts on cab with 10" bolts, add washers & self-locking nuts

- Need to assemble hoses & add fittings to valves & backing plates

- Need to mount the seat

Information regarding MoKan Bolts Order - 9/19 1110AM CST

- Ordered 90, 10" bolts on Monday, estimated arrval to MoKan was 9/18 or 9/19

- Tuesday 9/17 - Confirmed bolts would arrive on 9/19

- Thursday 9/19 - MoKan informs that order was not on track (their end), but being shipped on a ship (right now) - now sourcing alternative bolts

Production Meeting - 9/19

- Hydraulics schematics finished

- Wheel hubs status: none are done

- Wheel units: need to finish welds on wheel units; 20 min to finish one, 2 more set up for tacking & welding

- MoKan run today for 10" bolts

- Bobcat quick attach: INW

- Pivot: mounting plates for pivot are on...need to put the shaft going through the mounting plates to complete assembly; overall we are waiting on wheels to finish this

Production Meeting - 9/18

- Still need instructions with loader arms -- but they are assembled

- Instructions completed for the turning pivot

- Logic of completing the wheel hubs: parts are prepared; need to assemble & weld -- Gary & Marcin will work on two, Gary copying what Marcin is doing; Marcin will generate step procedures in Google Docs

- Need to put the ground hug pivot with the power cube

- Lucas may be available after 6pm

- Need Marcin to finish the hydraulic schematics

Production Meeting - 9/17

- Gary needs to finish Loader Arm & Quick Attach instructions

- The cab and power cube frame is built;

- MoKan did not have 10" bolts--we are using temp bolts and will swap when the bolts come in, ETA Thurs, 9/19

- Design Issue: The bucket attachment is too weak; reverting to earlier version of design

- Impact: James will integrate re-design

- Pivot instructions are done

- Need to grind down stands on the axle (cut about 1/2")

- Marcin will work on the wheel units -- need to ensure robust documentation of this process

- Tires -- we have 4; need to order 4 more tires -- Katie

- We now have "HabLab" modem in the workshop

Production Meeting - 9/16

- Completed: cutting of 4x4 tubing & bonding plates

- Need to finish cutting pivot plates

- Need to finish hydraulics schematics (meet w/Marcin)

- Katie is getting bolts from MoKan; we need inventory fasteners

- Marcin is picking up rims from Jason; may be able to pick up tires

- Otherwise, we still need to source tires -- critical point for tires: Wed (parts in hand, then mount them)

- Gary is finalizing work instructions

- Need to separate steel into modules

- Need Marcin to put together quick attach mounts (welding) -- need deliberate documentation of this step for instructionals

- Need to update shop inventory

Production Meeting - 9/15

- To cut: 4x4 w/ no holes

- Update shop inventory (need wifi in shop!)

- Call century link (Katie)

- Start quick connects

- Hydraulics schematics -- need Wed

- Tires

Logistics Requirements: To Do Sept 16

- Sweiger: wire mesh, sprocket

- MoKan: bolts; plus 90 x 10" zinc plated grade 2 bolts

- Jason: rims; tires?

Hydraulics

- September 13: The hydraulics diagram is good except it shows the motors wired in series. They should be wired in parallel. The series configuration shown will give us 1000 lb of pushing force, and the parallel configuration will give us 4000 lb of pushing force from our 30" diameter wheels.

- September 14 response: This makes sense. Are you asking for a new diagram showing all of this? No problem, but remember Rob's Fast, Good, Cheap Tiangle: You can only choose two.

- It sounds like a good set-up, but then there will be no hoses running between the joysticks.

Fast

/\

/ \

Cheap - - - - Good

Power Cube

- September 13: Note that the design is for one power cube only. If we use 2 power cubes - so we can run the pulverizer - then we need to connect one power cube to each valve, with the two valves being independent systems. This could by done if we route the Pulverizer and Loader Lift/Curl through the 3 spool joystick valve (first power cube), and the wheel drive/turning through the other valve (and second power cube).

- This means that each valve must have quick couplers, so we can rewire the system for the 2 power cube case.

- The bottom line is: fluid can't mix between the two power cubes, or it will begin to spill. Each power cube must have its own closed circuit, with no fluid mixing between the cubes.

Production Plan Meeting September 11

Overall Development

see also - [1]

Development as of September 10, 2013

Modules

Other than Modules

Final Assembly

- http://opensourceecology.org/wiki/File:Phoenix_Assembly_Method.odt Phoenix Assembly Method

Modular Wheel Units Assembly

See LifeTrac 6 Modular Wheel Units - Assembly

modules

arms

https://drive.google.com/folderview?id=0BwxMMqGvwTM-RkVycWVRbm5oN3c&usp=sharing

qa

https://drive.google.com/folderview?id=0BwxMMqGvwTM-QWI0RXJzMFhMR1U&usp=sharing

BOM

- FOR BOM SEE LifeTrac 6 Parts Order

Material, RFQ, and Work Requisition Form

V.09-01-13

V.09-06-13

V.09-17-13

Videos

Blog Posts

Future Work

Credits