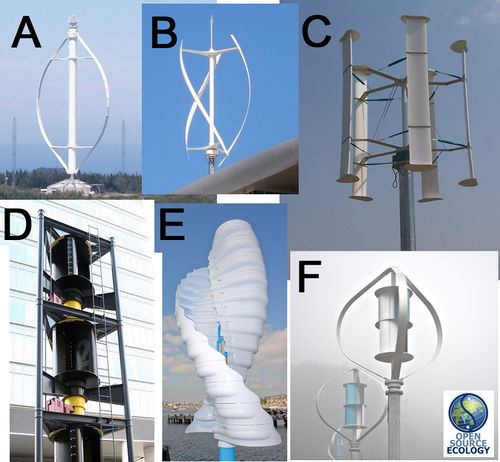

VAWT

Calculations

- Power Production - take this 16 kW VAWT - [2] at $65k in kit form (assumes $30k more for BOS). For average 6.5 m/s wind in Maysville, MO - power production is 4 kW for 8760 hours - or 35 MW hours! At 10 cents per kWhr - 35,000 kWhr is $3500 worth of electricity. Clear capacity to export to the grid.

- 7.4x4.7 diameter and height for a swept area of 35 sq m. If power proportional to swept area, then 3 kw at 6 m/s translates to 1 kW average power with a 12 sq meter swept area.

- Check out assembly - [3].

- Comparison to PV - $4/Watt vs 40 cents per watt for PV - 10x less cost for PV. Cost of wind can be reduced to: $3k generator (off shelf), $10k structure. 3" shaft and bearings - $30/foot for shaft of 10' length = $300 + $100 bearings. DIY direct drive PM generator cost should be explored. Brute force electronics can be done. Cost design calculations should be done.

- Sample structure - 1/2" wall square tubing legs -120' - $3240 for tower + concrete 10 yd ($1000) + BOS = $5k tower. Then blades - 60' vertical + 36' horiz = 100' more - $2700 -> $8k total structure. $3k gen. $2k power electronics. $2k BOS. $15k cost for 16 kW

Links

Tech assessment. Is the VAWT a feasible candidate for wind power? Low cost due to ground mounting are a potential advantage

- The HAWT school of WT design has a lot to say about VAWT: www.wind-works.org/cms/index.php?id=116

- discussion of pros and cons - [4]

- HAWT comparison - Bergey 10kW costs $48k + $65k to install. - [5]

- Good analysis. Conclusion is that the VAWT may be better in low wind conditions. Surprisingly, this piece also indicates that lower maintenance will not be a greater advantage because of lower electrical production. [6]. OSE analysis - if DIY cost levels are attained, then lower installation costs allow low wind areas to be tapped - poor wind resource areas are at an advantage. Moreover, if we assume that VAWTS con be lower technology - then VAWTS can attain better cost performance under the condition that the sole cost of an install is materials. This argument may change with a hydraulic drive train wind turbine, where the HAWT may be a clear winner. Material costs and output calculations can provide the solution.

Sourcing

- 50 kW brushless generator head, 1800 rpm - $2.2k [7]

Industry Standards

- Aeolos - up to 10 kW size - [8]. Price?

- ANew S1 - 16kW - $65k kit plus structure (total about $100k) - [9]

- 100kW turbine at $270k - [10]

Papers

- VAWT power controls - [11]. Possible advisors.

Alternative Design: VAWT as Water Lifting Device

To overcome the intermittency of wind, an alternative VAWT design may be a non-electric, purely mechanical water lifting device (see example). The water released from the reservoir can then power an electric generator whenever needed. Other mechanical power inputs can also be used to add water to the same reservoir (e.g. see Stirling Engine video from Tamera community where solar heat runs a water pump). The power of multiple wind turbines can easily be combined for more electrical power output. If the goal is mechanical power output, then an electric generator may not be needed at all. The design is flexible and multiple different generators can be hooked up. The reservoir has obvious dual uses, such as for gravity-fed irrigation or possibly even in aquaculture.