Universal CNC Axis: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 10: | Line 10: | ||

Larger axes will also be built, up to 2" for heavy duty CNC machining, with plastic parts sandwiched between metal plate as a plastic/metal composite structure. See calculations for beam deflection at [[Heavy_Duty_CNC_Construction_Set]]. | Larger axes will also be built, up to 2" for heavy duty CNC machining, with plastic parts sandwiched between metal plate as a plastic/metal composite structure. See calculations for beam deflection at [[Heavy_Duty_CNC_Construction_Set]]. | ||

=Working Document= | =Universal Axis - Working Document= | ||

*P1 - Visual Linked BOM (VLBOM) | *P1 - Visual Linked BOM (VLBOM) | ||

*P2 - [https://docs.google.com/presentation/d/1c16frI1XSWUaqCRtWsGnv5-GaXvNl6P6fXIkUY72CdA/edit#slide=id.g1841d4b58e_0_0 extruder stepper motor mounting] | *P2 - [https://docs.google.com/presentation/d/1c16frI1XSWUaqCRtWsGnv5-GaXvNl6P6fXIkUY72CdA/edit#slide=id.g1841d4b58e_0_0 extruder stepper motor mounting] | ||

Revision as of 03:07, 10 September 2017

Example of CNC Circuit Mill Configuration

Intro

The following is a 5/16" or 8 mm version of the universal CNC axis described at http://opensourceecology.org/3d-printer-construction-set-workshop/

Larger axes will also be built, up to 2" for heavy duty CNC machining, with plastic parts sandwiched between metal plate as a plastic/metal composite structure. See calculations for beam deflection at Heavy_Duty_CNC_Construction_Set.

Universal Axis - Working Document

- P1 - Visual Linked BOM (VLBOM)

- P2 - extruder stepper motor mounting

Concept

WebGL

Real

Build

Carriage

From Michel Dhoore in Belgium in 2016. Early prototype using larger carriage pieces for larger machines.

Frame

Axis

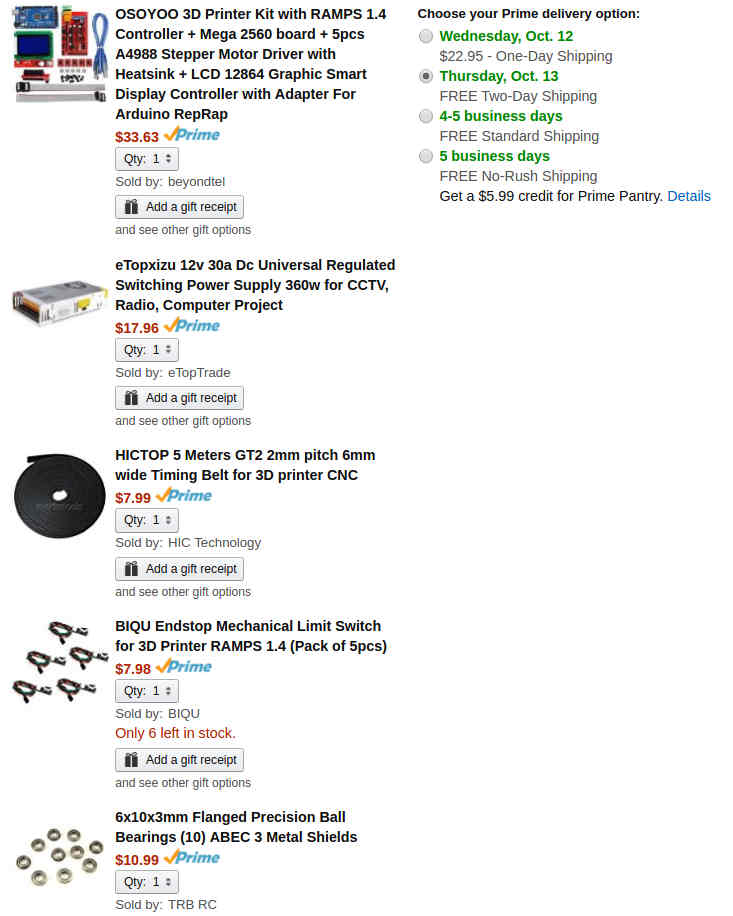

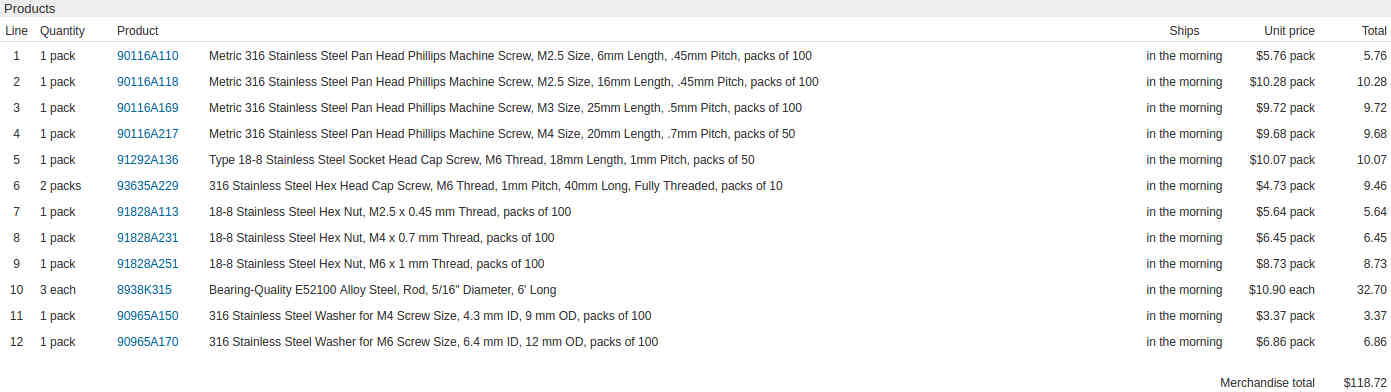

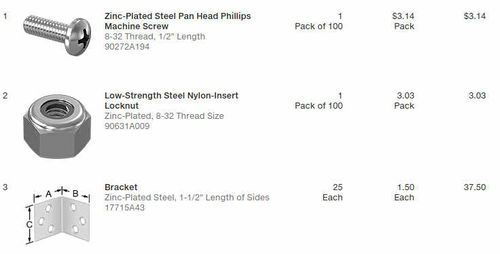

BOM

Order

Frame Parts

FreeCAD and STL Files for Printing

Originals from 2016 by Michel Dhoore

This file has the carriage belt tensioners, not shown below.

Universal Axis with Magnet Holes 2017

- File:Universal axis carriage side.fcstd. File:Universal axis carriage side.stl.

- File:Universal axis idler side.fcstd. File:Universal axis idler side.stl

- c

- If using 6x10x3 mm flanged bearings (See BOM), then need a 1 mm spacer: File:Idlerspacer.fcstd. File:Idlerspacer.stl

Fabrication

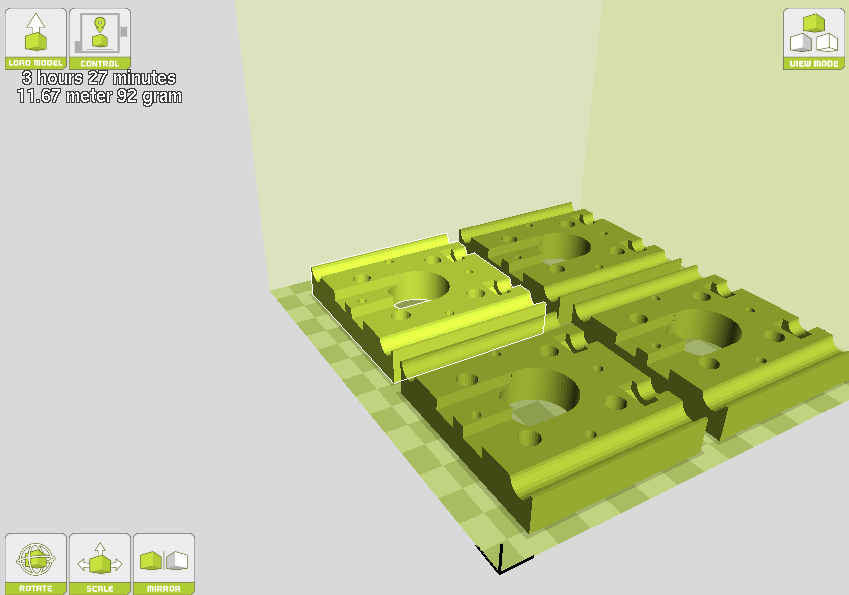

- Print time - 3hr27min for the idler end -

One Axis Attached to Frame

Applications

Links

- 1" Universal Axis

- OSE Germany appears to be doing non-coordinated development on this as well - https://wiki.opensourceecology.de/Erg%C3%A4nzungs-Set_Lineartrieb

- 3D Printer Design Evolution

- 3DP Construction Set workshops - December 2016 - [1]