Large Workshop Structure: Difference between revisions

Jump to navigation

Jump to search

| Line 9: | Line 9: | ||

**Insertion is possible from the top from a hatch in the roof. If using flat roofs, vertical stackability is high. | **Insertion is possible from the top from a hatch in the roof. If using flat roofs, vertical stackability is high. | ||

**In fact, all columns can be inserted, 2nd floor could be jacked up as a whole using the first roof and simple jacks at each post. Posts are pinned as they are jacked - crushing safety is guaranteed. | **In fact, all columns can be inserted, 2nd floor could be jacked up as a whole using the first roof and simple jacks at each post. Posts are pinned as they are jacked - crushing safety is guaranteed. | ||

**6x6 inch column can be grown on 1 acre of farm (see [[Farm Yields Per Acre]]) (400 kg/hr) - 10' of height =2.5 cu ft -> in | **6x6 inch column can be grown on 1 acre of farm (see [[Farm Yields Per Acre]]) (400 kg/hr) - 10' of height =2.5 cu ft of concrete => 1/10 of a (yard = 2000 kg) = 200 kg (1/2 hr production) at 10% cement -> in 3 minutes. For 20 columns - 1 hr of farm crop from an acre. | ||

***Corresponding steel growth is 50 lb/column *20 columns = 1000 kg -> 2.5 hours of steel melting. | |||

=Build and Data Collection= | =Build and Data Collection= | ||

Revision as of 23:54, 9 August 2023

Concept - Structural Space Frames

Details

- Extensive and Intensive scalability of indidvidual columns via size: LWH, and size of rebar

- Hollow core (tubular) also means that we can scale by internal superposition of modules

- Retrofittable concrete pillars - Example: 12" base structure, insert a 6" core with concrete for retrofitable vertical scalability of structures

- Insertion is possible from the top from a hatch in the roof. If using flat roofs, vertical stackability is high.

- In fact, all columns can be inserted, 2nd floor could be jacked up as a whole using the first roof and simple jacks at each post. Posts are pinned as they are jacked - crushing safety is guaranteed.

- 6x6 inch column can be grown on 1 acre of farm (see Farm Yields Per Acre) (400 kg/hr) - 10' of height =2.5 cu ft of concrete => 1/10 of a (yard = 2000 kg) = 200 kg (1/2 hr production) at 10% cement -> in 3 minutes. For 20 columns - 1 hr of farm crop from an acre.

- Corresponding steel growth is 50 lb/column *20 columns = 1000 kg -> 2.5 hours of steel melting.

Build and Data Collection

Build Time

Logistics: 1 day weld, 6 welders, cutting happens prior to weld. 1 day assemble. Joints are required. Connector system must be created for this system if build is to be rapid. Choices include u-bolts and plates.

Working Doc 2

Part Library

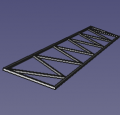

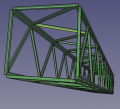

Workshop skeleton. - FreeCAD -File:Workshopskeleton.fcstd. Full file above 1 MB on gitlab - [1].

9 foot truss, 4-sided. - FreeCAD -File:9 foot column.fcstd

15 foot truss, 4-sided. - FreeCAD -File:15foottruss.fcstd

- Columntruss.png

8 foot truss, 4-sided. Double, used in columns. - FreeCAD -File:Columntruss.fcstd

8 foot truss, 4-sided. - FreeCAD -File:8footrebaruss.fcstd

12 foot truss, 4-sided. - FreeCAD -File:12footrebaruss.fcstd

3 foot truss. - FreeCAD -File:3foottruss.FCStd

Links

- Factor e Farm Improvements

- Large Covered Structure - initial hoop idea but flat hoops are not stable. Lesson: need to create stiff truss structures - triangular or square - to make the construction method robust.

- CNC Sawmill - also uses rebar trusses

- Rebar Truss Design Guide

Related

- FreeCAD script for printing interconnectable beams? [2]

![Workshop skeleton. - FreeCAD -File:Workshopskeleton.fcstd. Full file above 1 MB on gitlab - [1].](/images/thumb/c/c9/Workshopskleton.png/120px-Workshopskleton.png)