Rototiller/Manufacturing Instructions/Shaft and Motor Frame: Difference between revisions

Jump to navigation

Jump to search

(Created page with "{{Template:Soil Pulverizer Manufacturing Instructions Navbox}} =Overview= The shaft and motor frame supports the main shaft with the tines and provides a mounting location for th...") |

|||

| (10 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

{{Template:Soil Pulverizer Manufacturing Instructions Navbox}} | {{Template:Soil Pulverizer Manufacturing Instructions Navbox}} | ||

=Overview= | =Overview= | ||

The shaft and motor frame supports the main shaft with the tines and provides a mounting location for the motor. | {| | ||

|- | |||

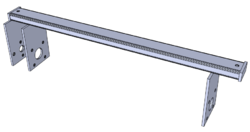

|[[file:Front_Holder_Weldment.PNG|250px]] | |||

|The shaft and motor frame supports the main shaft with the tines and provides a mounting location for the motor. | |||

|} | |||

=Tools Required= | =Tools Required= | ||

=Materials Required= | =Materials Required= | ||

{| class="wikitable" | |||

|- | |||

! align="center" |'''TYPE''' | |||

! align="center" |'''SIZE''' | |||

! align="center" |'''QTY.''' | |||

|- | |||

| Flat|| 0.5" x 2" x 4.25" || align="center"|2 | |||

|- | |||

| Flat|| 0.5" x 8" x 12" || align="center"|3 | |||

|- | |||

| Rectangular Tubing|| 2" x 4" x 1/4"Thick x 56"|| align="center"|1 | |||

|} | |||

= | =Parts List and Drawings= | ||

{| class="wikitable" | |||

|- | |||

! align="center" |'''ITEM NO.''' | |||

! align="center" |'''PART NAME''' | |||

! align="center" |'''QTY.''' | |||

|- | |||

| align="center" |1 || [[:file:100523.JPG| Cross Tube]] || align="center"|1 | |||

|- | |||

| align="center" |2 || [[:file:100524.JPG| End Plate, Cross Tube]] || align="center"|2 | |||

|- | |||

| align="center" |3 || [[:file:100525.JPG| Plate, Motor End]] || align="center"|1 | |||

|- | |||

| align="center" |4 || [[:file:100526.JPG| Plate, Bearing]] || align="center"|2 | |||

|} | |||

=Assembly= | =Fabrication and Assembly Instructions= | ||

{| class="wikitable" | |||

|- | |||

! align="center" |'''Assembly Name''' | |||

! align="center" |'''QTY.''' | |||

|- | |||

| [[:file:100522.JPG| Front Holder Welded Assembly]] || align="center"|1 | |||

|} | |||

# Cut piece parts as per part drawings | |||

# Weld end plates onto rectangular cross tube | |||

# Weld motor end plate and two bearing plates as per assembly drawing. Ensure each is welded strongly all around and that they are all parallel to each other | |||

Latest revision as of 21:12, 23 December 2011

| |||||||||||||||||||

Overview

|

The shaft and motor frame supports the main shaft with the tines and provides a mounting location for the motor. |

Tools Required

Materials Required

| TYPE | SIZE | QTY. |

|---|---|---|

| Flat | 0.5" x 2" x 4.25" | 2 |

| Flat | 0.5" x 8" x 12" | 3 |

| Rectangular Tubing | 2" x 4" x 1/4"Thick x 56" | 1 |

Parts List and Drawings

| ITEM NO. | PART NAME | QTY. |

|---|---|---|

| 1 | Cross Tube | 1 |

| 2 | End Plate, Cross Tube | 2 |

| 3 | Plate, Motor End | 1 |

| 4 | Plate, Bearing | 2 |

Fabrication and Assembly Instructions

| Assembly Name | QTY. |

|---|---|

| Front Holder Welded Assembly | 1 |

- Cut piece parts as per part drawings

- Weld end plates onto rectangular cross tube

- Weld motor end plate and two bearing plates as per assembly drawing. Ensure each is welded strongly all around and that they are all parallel to each other