Bulldozer Geardown: Difference between revisions

Jump to navigation

Jump to search

| Line 28: | Line 28: | ||

==Review of Day 2 by MJ== | ==Review of Day 2 by MJ== | ||

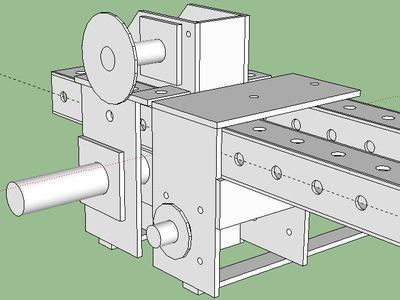

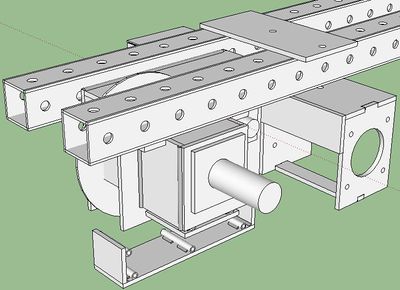

It turns out that the sprocket sizes make the geardown particularly large. So I am looking at [[Page 82 of Martin Sprocket Catalogue]] | It turns out that the sprocket sizes make the geardown particularly large. So I am looking at [[Page 82 of Martin Sprocket Catalogue]] and see that the smallest 100 pitch sprocket is 8 teeth, Diameter of 3.8". Shaft is smaller than our 1-7/8" size, so the only way we can use it is if we weld on our own hub. | ||

=Initial Conceptual Design= | =Initial Conceptual Design= | ||

Revision as of 22:57, 2 June 2013

Design Proposals

Day 1 - Dorkmo

- Folder of first draft Sketchup Files - [1]

Design Review

Further Conceptual Design

Geardown Iteration Day 2 by Dorkmo

Review of Day 2 by MJ

It turns out that the sprocket sizes make the geardown particularly large. So I am looking at Page 82 of Martin Sprocket Catalogue and see that the smallest 100 pitch sprocket is 8 teeth, Diameter of 3.8". Shaft is smaller than our 1-7/8" size, so the only way we can use it is if we weld on our own hub.

Initial Conceptual Design

Design Conditions of Satisfaction

- Uses exising Quick Connect Wheel rotor - its shaft output.

- Geardown module is CNC cut from 1/2" steel sheet

- Notches are made such that the structure can be assembled only one way

- Mechanism for quick disassembly is included

- Mechanism for tensioning the chain drive is included

- Enclosure allows easy replacement of parts

- Quick attachment of wheel onto the output shaft of geardown module is possible

- Wheel is secured via a keyway

- Input shaft is 1-7/8" thick, output shaft is 3" thick

- Standard cold rolled shaft is used

- Mechanism for retaining axial thrust is included

- Geometry must line up for the connection to Quick Attach Wheel

- Guards protect any exposed chains/sprockets for safety

- Method of coupling to existing Quick Connect Wheel must be used - via chain drive - while considering geometry of frame a drive components

- Quick Connect Wheel and Geardown units must be sufficiently stable to maintain chain tension. Tightening mechanism must lock in place.

- Reference must be provided to verify existence of off-shelf parts

- 100 Pitch Chain must be used.

- Concept must show approximate dimensions (+/- 2") of the geardown structure

- Geardown unit must be no more than 250 lbs in weight

LifeTrac Existing Design

- LifeTrac - LifeTrac_III frame documentation

- Quick Connect Wheels - shows dimensions

Parts

Sprockets

Notes: practical limit for 100 pitch ~ 36 teeth - or 15" OD - [2]

80#

- 1-7/8" bore 20T - [7]

- 1-7/8" bore 14T - [8]

- 1-7/8" bore 13T 2.3285" O.R. - [9]

- 2" bore 13T - [10]

- 2" bore 22T 3.79" O.R. - [11]

100#

- 2" bore dia, 11T, 2.504" O.R. - [12]

- 26 tooth - OD 11" - $10 - Surpluscenter - [13]

- 2517 2. tapered bushing [14]

- 2.938" bore dia, 16T - $123 - [15]

- 2.938" bore dia, 25T, 5.3225" O.R. - [16]

- 2" bore dia, 25T - [17]

- 36T 3020 taper bushing [18]

- 3020 3. bushing [19]

tapered sets

1-7/8" shaft to 13T 100# sprocket

- keyed 1-7/8" to 2012 size tapered bushing

- 2012 tapered bore, 13T, 2.9105" O.R.

Sourcing Problems

- 100# chain sprokets hard to find

- 80# chain sprokets with bore dia above 2" hard to find

- minimum teeth on 100# sprocket for 3" shaft with 3020 tapered bushing = 28

- max shaft size for a bored to size 100# sprocket = 2.938