Gary DeMercurio Log: Difference between revisions

m (Marcin moved page Gary Log to Gary DeMercurio Log without leaving a redirect) |

|||

| (85 intermediate revisions by 5 users not shown) | |||

| Line 1: | Line 1: | ||

= | =Wednesday Sept 25, 2013= | ||

Completed | *Completed review of TCM for Audrey | ||

*Started organization on back hoe, included Daniel B for collaborative design efforts prior to his arrival | |||

*Internet went down for 5 hours, did what I could with smart phone and computer, was able to organize my home office! | |||

*Started on Prototype assessment while trying to make a lessons learned to incorporate into future builds. | |||

*Due to Internet issues hope to have BOM and cost completed tomorrow. | |||

= | ==Goals for the Week== | ||

*Complete After Action items for LT6 Build | |||

*Get started on New Project Back Hoe and Iron Worker | |||

*Burn down past due items, get better organization in my home office. | |||

==Goal Completion== | |||

*Completed Life Track 6 with minimum man power. | |||

=Monday / Tuesday Comp Days= | |||

=Sunday Sept 22, 2013= | |||

*completed hydraulic mounting | |||

*had issues with the power beyond sleeves. They seemed yo be blocking a port or something that would make the pump bog down and fail, stalling the engine. Similar issue with life track 5. Correction was to take the power beyond sleeves out and trim them down a bit, this opens whatever it is blocking and enables the system to work. Not sure if its a issue with the sleeve, if there is something were missing. Correction did work however. | |||

*Life track 6 First test was completed needs the following adjustments/ Finishes: | |||

1. Stops need to be put into place for the tilt as it will go too far. | |||

2. Handles need to be welded to both the articulating pivot and ground hug pivot. | |||

3. Floor for both the cab and the hydraulic bay need to be welded in | |||

4. Wire mesh for the safety cage needs to be added | |||

5. Loader arms need to be tested to see if a weld will be required for the corners | |||

6. Needs hosing to be rerouted for dual powercubes / As well as more suitable that hosing for testing. "Neater" | |||

7. Power Cube needs to be held in place | |||

8. Channel or something that will protect the hyd tubing from the powercube needs to be added. | |||

9. Bobcat QA need to be attached and tested. | |||

Hours Worked: 6 | |||

=Saturday Sept 21, 2013= | |||

*All cyl mounted and tested for geometry without power | |||

Had some spacing and geometry issue that were fixed with some movement of the mounts | |||

*Hydraulics mounted and routed | |||

*started testing procedures, however had to cut short due to lack of hydraulic fluid, will resume in the morning. | |||

So far so good, one cyl is routed backwards from how we want it, everything else for the short time we had seemed to be working well. No clearance issues yet. May have to put a stop on for the tilt as it travels past parallel, we will see Sunday. | |||

Hours worked: 17 | |||

=Friday Sept 20, 2013= | |||

*Now have a rolling chassis | |||

*Got started on the hydraulics, 2 hyd cyl mounted, need to finish up on the pins. | |||

*Hydraulics/Seat mount/powercube mount is what remains. | |||

Hours worked: 11.5 | |||

=Thursday Sept 19, 2013= | |||

*Completed the bobcat quick attach | |||

*attached 2 wheel mounts and tires to the powercube. ready to be attached to the cab. | |||

*many issues arose with the wheel mounts. The space for the wheel mounts to mount to the frame was too small, forcing us to literally use blunt force to try and get them on.... not a one man job. Holes on the top of the wheel mounts do not align properly with the holes on the bottom making the use of 1" bolts impossible without drilling out the frame. Due to the extremely tight space where the wheel mounts attach to the frame, the fit issue was further exacerbated due to the welds themselves adding another 1/16 or so of an inch. Wheel mounts needed, hammers, pry bar, screwdrivers, bolts (for hammering on to align holes) and grinding of the wheel mount, weld and frame to finally get them to fit. | |||

*Wheel hubs cannot be taken off with just outer pin, need to be removed with the lug nuts like a normal car/truck/tractor. Utilized this incase the pin bends, the wheel wont be stuck. Can still unpin the rear pin to take the wheel and hub off. | |||

*Things still not put away and returned in the shop. Many things that were organized have been moved out of the order they were placed and mixed up and not put back. This makes it extremely hard to #1 keep the shop organized #2 take inventory #3 keep from losing items in the shop. | |||

Hours worked: 17 | |||

=Wednesday Sept 18, 2013= | |||

[[File:PivotWI.odt]] | |||

*Completed powercube with ground hug pivot installation. | |||

*Completed 50% of Bobcat quick attach, some cutting issues with what we received from the CnC shop, a tad too big, will have to grind down tomorrow. | |||

*Articulating pivot mounts placed and ready for pivot and hyd cyl. | |||

*Pins cut for bucket. | |||

*Life track build fell behind today due to lack of wheels/wheel mounts. Had planned on having at least two completed this morning. Almost have one. | |||

*Need to have wheels/wheel mounts completed by early afternoon. | |||

*Still waiting for hydraulic schematics to be completed. | |||

*Shop not being taken care of properly, have created a power point for with examples of what does not adhere to shop rules, and what does. | |||

[[File:ShopClean.odp]] | |||

Hours worked: 17 | |||

=Tuesday Sept 17,2013= | |||

[[file:oldlifetrac.skp]] | |||

[[file:loaderarms.skp]] | |||

*Finished the Axle for the power cube. Due to the separation of the pivot plates it made the over all width the exact size of the powercube. Had to make multiple cuts to get it to fit. Could try and account for error but the amount of error varies. | |||

*Corrected an issue with the loader arm pivoting due to design issue. Need to ensure going forward to use Dozuki for current model and only give admin rights to staff so it doesn't change. Not the first issue for this build. | |||

*Power cube ready to connect to articulating pivot, then waiting on Wheel mounts to be complete. | |||

*Basic cab structure complete, waiting on wheel mounts. | |||

= | ==Goals for the Week== | ||

*Complete Life track 6 | |||

= | |||

= | ==Goal Completion== | ||

*Finished design of tractor. | |||

*Cut list complete and cut. | |||

*Work Flow complete. | |||

*Work instructions complete except for loader arms (took 4 DPV's 2-3 days to complete WI for last life track, I've had to complete these on my own over the last 4 days.) Had to leave out how bolts went in do to time constraints, need to work in how they are placed for next build (to avoid bolt being stuck and not able to remove after construction)*****. | |||

*Completed more than 50% of the frame in one day. | |||

Hours Worked: 12 | |||

=Monday Sept 16, 2013= | |||

*Work instructions, found multiple issues with work instruction due to superimposed tubes that were "inside" other that weren't noticed until the model was "blown apart". | |||

*Rewired the workshop so that it has wi-fi for the build/future. | |||

*Completed work instructions along with parts list for Cab Module. | |||

*Helped with co worker with some presentation issue to free them up for tractor duty. | |||

*Build meeting with DPV's, outlined build instructions, workshop layout, remaining cuts, welds. | |||

*Tech meeting with Marcin to go over current issues, WIP, hyd schematics, quick connect wheel mounts. | |||

*Reconfigured the network and "undid" what the tech help person messed up this weekend. Wireless is back to normal. Re-connected the printer to the network as it wasn't working with the configuration that we were left with from the tech help. | |||

[[File:WorkInstructionsCab.odp]] | |||

[[File:WorkInstructionsPowercube.odp]] | |||

Build: | |||

*Cab complete / waiting on Wheel mounts | |||

*Power cube / Basic structure complete | |||

*Axle for powercube 60% complete, in place and tacked, needs to be fitted to the powercube frame, as of now .5 inch discrepancy. | |||

Hours Worked: 18 | |||

= | =Sunday Sept 15, 2013= | ||

*Completed Cab Instructions, 80% complete with all others. | |||

*Researched adobe homes, found multiple instances of clay bricks set with mortar, 2000+ sqft build in a single day. End result is a permanent structure that is a "real home" utilized real stucco for the outside is some cases, others utilized the brick as it's weatherproof, unlike our current configuration. Great example of what we should be working towards. | |||

Hours worked: 8 | |||

=Saturday Sept 14, 2013= | |||

Continue to work on Work Instructions for cab, loader arms, pivot and power cube as numerous issues creeped into the Work instructions due to design creep. | |||

Hours worked: 17 | |||

Completed cut list. | |||

Had multiple issues with incorrect parts super imposed into the build that caused issues with the cut list. | |||

=Friday Sept 13, 2013= | |||

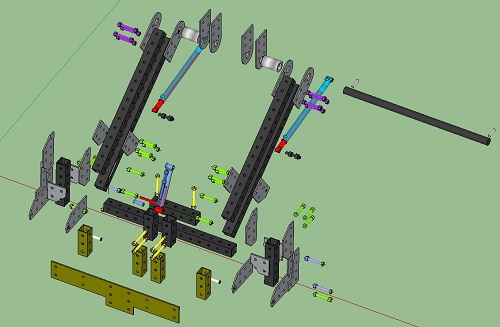

Corrected power cube fit issues which made the previous Work Instructions obsolete. Completed the exploded diagram of the Cab and loader arms along with an over all Parts list / cut list for the build. | |||

[[File:PartsList.skp]] | |||

[[File:ExplodedCab.Jpg]] | |||

[[File:ExplodedLA.jpg]] | |||

[[File:lifetrac6PCRD(2).skp]] | |||

=Thursday Sept 12, 2013= | |||

*Finished up with some design issues concerning the loader arms and cylinders. | |||

*Completed the work instructions for the power cube | |||

*Started on the Work Instructions for the Cab module. | |||

= | =Wednesday Sept 11, 2013= | ||

*Completed work instructions for the power cube module | |||

*Created burn down list for build | |||

= | =Tuesday Sept 10, 2013= | ||

= | ==Goals for the Week== | ||

Finished design of tractor | |||

Start cutlist | |||

Work Flow | |||

= | ==Goal Completion== | ||

*worked on templates / refined Product Lead process | |||

*material received | |||

*Helped with Dozuki | |||

=Monday Sept 9, 2013= | |||

Travel to FeF | |||

=Friday Sept 6, 2013= | |||

*Watched more videos for Auto Inventor, good progress but it is very different than what I am used to with Catia. is going to take more time than I have to do what I want with it prior to the tractor build. Ordered a manual that will hopefully make some of the more tedious things easier with shortcuts, just going to take a lot of time getting familiar. | |||

*looked for some wheels and tires, found some 31" tires that would work, prices between 150-220$ each at multiple locations. was trying to find a rim and tire set, nothing that would fit the tractor that was reasonable. | |||

=Thursday | =Thursday Sept 5, 2013= | ||

*Watched 4 hours of video for Auto Inventor to try and familiarize myself. hoping to be able to run some stress analysis as some point. 4 hours + stopping and starting to try and learn the tools, very time consuming but informative. | |||

*Updates program managers for times | |||

*Updated program manager to reflect any issues that were behind schedule adding notes to each. | |||

*Movers came. | |||

=Wednesday Sep 4, 2013= | |||

*Continued to work on burn down list of deliverables. | |||

*Read Lean Start as well as some research to better answer Daniel question about rapid prototyping as well as seeing if it was a process we could institute at OSE. As of now its not, it does have some good information that we could incorporate however when were ready. | |||

=Tuesday Sept 3, 2013= | |||

Things to do: | |||

Call Honda | |||

Check Bobcat Quick | |||

Tractor BOM | |||

Wheels and tires | |||

Work Instructions | |||

Completed the Relevance section on the Master Dev board, worked on the board most of the day coming up with things RC would be able to help with. Finished a few Dozuki categories, want to add another section for research. | |||

= | ==Goals for Week== | ||

*Continue working on templates / Continue refining Product Lead process | |||

*Build Prep for next week - Ensure material delivered on time. Proper material is received and adequate for build. Order any additional tooling. | |||

*Help with Dozuki | |||

==Goal Completion== | |||

*Get all parts ordered for Life track | |||

*Complete initial model with hyd basic structure and all systems complete | |||

*work on burn down plan with templates and web pages for development. | |||

=Older Entries= | =Older Entries= | ||

* | *[[Gary Log - August 2013]] | ||

*[[Gary Log - July 2013]] | |||

*[[Gary Log - June 2013]] | |||

*[[Gary Log - May 2013]] | |||

*[[Gary Log - April 2013]] | |||

[[Category:Personal Logs]] | |||

Latest revision as of 00:25, 13 February 2020

Wednesday Sept 25, 2013

- Completed review of TCM for Audrey

- Started organization on back hoe, included Daniel B for collaborative design efforts prior to his arrival

- Internet went down for 5 hours, did what I could with smart phone and computer, was able to organize my home office!

- Started on Prototype assessment while trying to make a lessons learned to incorporate into future builds.

- Due to Internet issues hope to have BOM and cost completed tomorrow.

Goals for the Week

- Complete After Action items for LT6 Build

- Get started on New Project Back Hoe and Iron Worker

- Burn down past due items, get better organization in my home office.

Goal Completion

- Completed Life Track 6 with minimum man power.

Monday / Tuesday Comp Days

Sunday Sept 22, 2013

- completed hydraulic mounting

- had issues with the power beyond sleeves. They seemed yo be blocking a port or something that would make the pump bog down and fail, stalling the engine. Similar issue with life track 5. Correction was to take the power beyond sleeves out and trim them down a bit, this opens whatever it is blocking and enables the system to work. Not sure if its a issue with the sleeve, if there is something were missing. Correction did work however.

- Life track 6 First test was completed needs the following adjustments/ Finishes:

1. Stops need to be put into place for the tilt as it will go too far.

2. Handles need to be welded to both the articulating pivot and ground hug pivot.

3. Floor for both the cab and the hydraulic bay need to be welded in

4. Wire mesh for the safety cage needs to be added

5. Loader arms need to be tested to see if a weld will be required for the corners

6. Needs hosing to be rerouted for dual powercubes / As well as more suitable that hosing for testing. "Neater"

7. Power Cube needs to be held in place

8. Channel or something that will protect the hyd tubing from the powercube needs to be added.

9. Bobcat QA need to be attached and tested.

Hours Worked: 6

Saturday Sept 21, 2013

- All cyl mounted and tested for geometry without power

Had some spacing and geometry issue that were fixed with some movement of the mounts

- Hydraulics mounted and routed

- started testing procedures, however had to cut short due to lack of hydraulic fluid, will resume in the morning.

So far so good, one cyl is routed backwards from how we want it, everything else for the short time we had seemed to be working well. No clearance issues yet. May have to put a stop on for the tilt as it travels past parallel, we will see Sunday.

Hours worked: 17

Friday Sept 20, 2013

- Now have a rolling chassis

- Got started on the hydraulics, 2 hyd cyl mounted, need to finish up on the pins.

- Hydraulics/Seat mount/powercube mount is what remains.

Hours worked: 11.5

Thursday Sept 19, 2013

- Completed the bobcat quick attach

- attached 2 wheel mounts and tires to the powercube. ready to be attached to the cab.

- many issues arose with the wheel mounts. The space for the wheel mounts to mount to the frame was too small, forcing us to literally use blunt force to try and get them on.... not a one man job. Holes on the top of the wheel mounts do not align properly with the holes on the bottom making the use of 1" bolts impossible without drilling out the frame. Due to the extremely tight space where the wheel mounts attach to the frame, the fit issue was further exacerbated due to the welds themselves adding another 1/16 or so of an inch. Wheel mounts needed, hammers, pry bar, screwdrivers, bolts (for hammering on to align holes) and grinding of the wheel mount, weld and frame to finally get them to fit.

- Wheel hubs cannot be taken off with just outer pin, need to be removed with the lug nuts like a normal car/truck/tractor. Utilized this incase the pin bends, the wheel wont be stuck. Can still unpin the rear pin to take the wheel and hub off.

- Things still not put away and returned in the shop. Many things that were organized have been moved out of the order they were placed and mixed up and not put back. This makes it extremely hard to #1 keep the shop organized #2 take inventory #3 keep from losing items in the shop.

Hours worked: 17

Wednesday Sept 18, 2013

- Completed powercube with ground hug pivot installation.

- Completed 50% of Bobcat quick attach, some cutting issues with what we received from the CnC shop, a tad too big, will have to grind down tomorrow.

- Articulating pivot mounts placed and ready for pivot and hyd cyl.

- Pins cut for bucket.

- Life track build fell behind today due to lack of wheels/wheel mounts. Had planned on having at least two completed this morning. Almost have one.

- Need to have wheels/wheel mounts completed by early afternoon.

- Still waiting for hydraulic schematics to be completed.

- Shop not being taken care of properly, have created a power point for with examples of what does not adhere to shop rules, and what does.

Hours worked: 17

Tuesday Sept 17,2013

- Finished the Axle for the power cube. Due to the separation of the pivot plates it made the over all width the exact size of the powercube. Had to make multiple cuts to get it to fit. Could try and account for error but the amount of error varies.

- Corrected an issue with the loader arm pivoting due to design issue. Need to ensure going forward to use Dozuki for current model and only give admin rights to staff so it doesn't change. Not the first issue for this build.

- Power cube ready to connect to articulating pivot, then waiting on Wheel mounts to be complete.

- Basic cab structure complete, waiting on wheel mounts.

Goals for the Week

- Complete Life track 6

Goal Completion

- Finished design of tractor.

- Cut list complete and cut.

- Work Flow complete.

- Work instructions complete except for loader arms (took 4 DPV's 2-3 days to complete WI for last life track, I've had to complete these on my own over the last 4 days.) Had to leave out how bolts went in do to time constraints, need to work in how they are placed for next build (to avoid bolt being stuck and not able to remove after construction)*****.

- Completed more than 50% of the frame in one day.

Hours Worked: 12

Monday Sept 16, 2013

- Work instructions, found multiple issues with work instruction due to superimposed tubes that were "inside" other that weren't noticed until the model was "blown apart".

- Rewired the workshop so that it has wi-fi for the build/future.

- Completed work instructions along with parts list for Cab Module.

- Helped with co worker with some presentation issue to free them up for tractor duty.

- Build meeting with DPV's, outlined build instructions, workshop layout, remaining cuts, welds.

- Tech meeting with Marcin to go over current issues, WIP, hyd schematics, quick connect wheel mounts.

- Reconfigured the network and "undid" what the tech help person messed up this weekend. Wireless is back to normal. Re-connected the printer to the network as it wasn't working with the configuration that we were left with from the tech help.

File:WorkInstructionsPowercube.odp

Build:

- Cab complete / waiting on Wheel mounts

- Power cube / Basic structure complete

- Axle for powercube 60% complete, in place and tacked, needs to be fitted to the powercube frame, as of now .5 inch discrepancy.

Hours Worked: 18

Sunday Sept 15, 2013

- Completed Cab Instructions, 80% complete with all others.

- Researched adobe homes, found multiple instances of clay bricks set with mortar, 2000+ sqft build in a single day. End result is a permanent structure that is a "real home" utilized real stucco for the outside is some cases, others utilized the brick as it's weatherproof, unlike our current configuration. Great example of what we should be working towards.

Hours worked: 8

Saturday Sept 14, 2013

Continue to work on Work Instructions for cab, loader arms, pivot and power cube as numerous issues creeped into the Work instructions due to design creep.

Hours worked: 17

Completed cut list.

Had multiple issues with incorrect parts super imposed into the build that caused issues with the cut list.

Friday Sept 13, 2013

Corrected power cube fit issues which made the previous Work Instructions obsolete. Completed the exploded diagram of the Cab and loader arms along with an over all Parts list / cut list for the build.

Thursday Sept 12, 2013

- Finished up with some design issues concerning the loader arms and cylinders.

- Completed the work instructions for the power cube

- Started on the Work Instructions for the Cab module.

Wednesday Sept 11, 2013

- Completed work instructions for the power cube module

- Created burn down list for build

Tuesday Sept 10, 2013

Goals for the Week

Finished design of tractor Start cutlist Work Flow

Goal Completion

- worked on templates / refined Product Lead process

- material received

- Helped with Dozuki

Monday Sept 9, 2013

Travel to FeF

Friday Sept 6, 2013

- Watched more videos for Auto Inventor, good progress but it is very different than what I am used to with Catia. is going to take more time than I have to do what I want with it prior to the tractor build. Ordered a manual that will hopefully make some of the more tedious things easier with shortcuts, just going to take a lot of time getting familiar.

- looked for some wheels and tires, found some 31" tires that would work, prices between 150-220$ each at multiple locations. was trying to find a rim and tire set, nothing that would fit the tractor that was reasonable.

Thursday Sept 5, 2013

- Watched 4 hours of video for Auto Inventor to try and familiarize myself. hoping to be able to run some stress analysis as some point. 4 hours + stopping and starting to try and learn the tools, very time consuming but informative.

- Updates program managers for times

- Updated program manager to reflect any issues that were behind schedule adding notes to each.

- Movers came.

Wednesday Sep 4, 2013

- Continued to work on burn down list of deliverables.

- Read Lean Start as well as some research to better answer Daniel question about rapid prototyping as well as seeing if it was a process we could institute at OSE. As of now its not, it does have some good information that we could incorporate however when were ready.

Tuesday Sept 3, 2013

Things to do:

Call Honda

Check Bobcat Quick

Tractor BOM

Wheels and tires

Work Instructions

Completed the Relevance section on the Master Dev board, worked on the board most of the day coming up with things RC would be able to help with. Finished a few Dozuki categories, want to add another section for research.

Goals for Week

- Continue working on templates / Continue refining Product Lead process

- Build Prep for next week - Ensure material delivered on time. Proper material is received and adequate for build. Order any additional tooling.

- Help with Dozuki

Goal Completion

- Get all parts ordered for Life track

- Complete initial model with hyd basic structure and all systems complete

- work on burn down plan with templates and web pages for development.