Charcoal/Steam Powerplant In Shipping Containers: Difference between revisions

< Charcoal

Jump to navigation

Jump to search

mNo edit summary |

mNo edit summary |

||

| Line 1: | Line 1: | ||

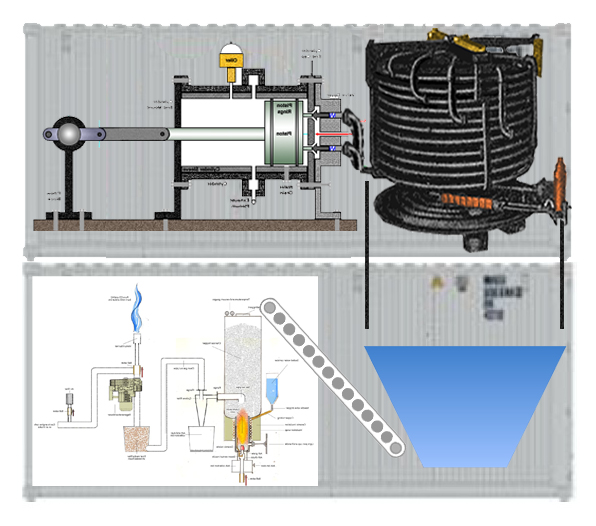

[[File:BioenergySteamCharcoal.jpg|thumb|596px| A [[Kon-Tiki Kiln]] (lower right) creates charcoal that can be dumped out to the right as biochar, or onto a hopper (left) where a conveyor belt moves it to a [[Troy Martz Gasifier]] that powers an internal combustion engine for electricity generation. The waste heat rises into a [[Steam Generator]] that powers a [[Steam Engine]].]] | [[File:BioenergySteamCharcoal.jpg|thumb|596px| A [[Kon-Tiki Kiln]] (lower right) creates charcoal that can be dumped out to the right as biochar, or onto a hopper (left) where a conveyor belt moves it to a [[Troy Martz Gasifier]] that powers an internal combustion engine for electricity generation. The waste heat rises into a [[Steam Generator]] that powers a [[Steam Engine]].]] | ||

This quick draft is a concept for a small, versatile portable power plant in two [[shipping containers]]. | This quick draft is a concept for a small, versatile portable power plant in two [[shipping containers]]. Any kind of dry biomass can be used as fuel, although wood probably works best. It produces electricity in two ways: from gasified charcoal in an internal combustion engine as well as from waste heat in a [[steam engine]]. Alternative products are [[biochar]] (if not gasified) and steam (if not used to power the steam engine). | ||

==Description (see figure)== | ==Description (see figure)== | ||

Revision as of 21:29, 27 August 2016

A Kon-Tiki Kiln (lower right) creates charcoal that can be dumped out to the right as biochar, or onto a hopper (left) where a conveyor belt moves it to a Troy Martz Gasifier that powers an internal combustion engine for electricity generation. The waste heat rises into a Steam Generator that powers a Steam Engine.

This quick draft is a concept for a small, versatile portable power plant in two shipping containers. Any kind of dry biomass can be used as fuel, although wood probably works best. It produces electricity in two ways: from gasified charcoal in an internal combustion engine as well as from waste heat in a steam engine. Alternative products are biochar (if not gasified) and steam (if not used to power the steam engine).

Description (see figure)

- Two 20 ft. shipping containers are used: the lower container is the carbonization/gasifier unit and the upper one is the steam / steam engine unit

- a charcoal-making unit similar to the Kon-Tiki Kiln is used for "open burn" pyrolysis

- the charcoal can be used as biochar

- alternatively, charcoal can be fed into a Troy Martz Gasifier

- "waste heat" rises into a Steam Generator

- Steam powers Steam Engine

Considerations / Problems

- the configuration of the Troy Martz Gasifier will have to be modified significantly. This is just a quick sketch.

- similarly, the configuration of the Kon-Tiki Kiln will also have to be very different. It is not clear that the dumping option is easy to achieve.

- since the walls of the shipping containers already act as an air barrier, the requirements for the geometry of the Kon-Tiki Kiln are not as strict as for a free-standing kiln

- Charcoal coming out of the kiln would burn when exposed to air, so the transfer to the gasifier would have to be quick

- Carbon monoxide release is a potential problem

- alternative to the conveyor belt is some kind of auger that transfers the hot charcoal into the holding tank.

- the waste heat from the Troy Martz Gasifier can be ducted to the Steam Generator for increased overall efficiency

- the Kon-Tiki Kiln has to be relatively accessible from all sides to allow fuel loading

- superheated steam may also be produced if the steam coming out of the steam generator is ducted back through the kiln.