Steam Engine Design: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 60: | Line 60: | ||

# Consider designing an exhaust manifold from the start. | # Consider designing an exhaust manifold from the start. | ||

# Visit Bill Ryan north of Chicago who has experience with making bash valves. | # Visit Bill Ryan north of Chicago who has experience with making bash valves. | ||

# Don't use stainless steel as a cylinder line. | |||

# Consider 12v electric system for fans, solenoids, relays, water level sensors, and starter motor. | |||

Revision as of 16:06, 3 May 2011

Main > Energy > Steam Engine

This page will be used to describe the OSE Open Source Steam Engine design, design issues, and completed drawings.

See bump valve prior art - http://www.rossen.ch/solar/wcengine.html

See also:

Prototype One

Steam Fires

Steam Expands

Steam Vents

Description

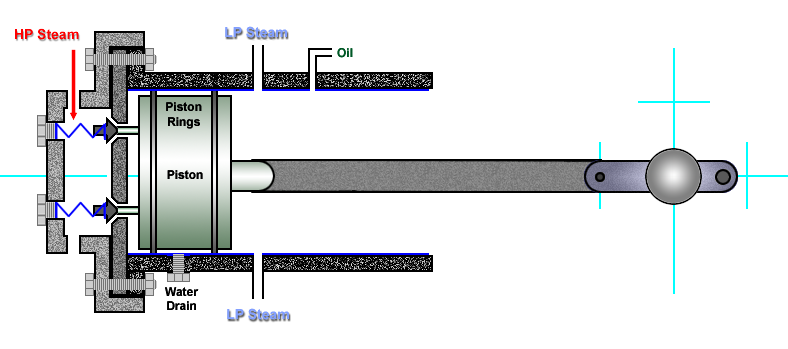

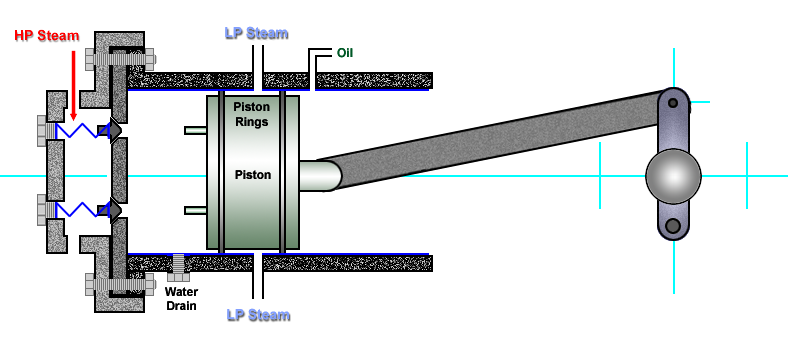

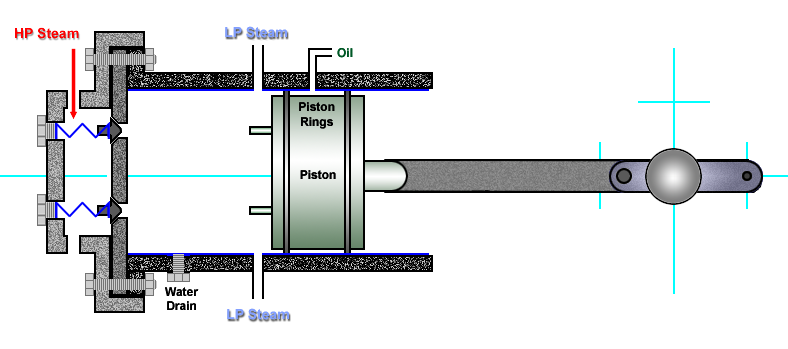

This is a single-action uniflow steam engine that uses a bump valve to admit steam and an exhaust vent to emit cooled steam. Some of the features of this design include:

- Simple design with a mix of fabricated and off-the-shelf parts.

- Modular and stackable - cylinders can be ganged together to increase power.

- Easy assembly - minimal welding

- Repairable - comes apart for cleaning, maintenance, and repair.

- Easy fabrication - lathing, milling, cutting, and drilling.

- Self-lubricating - oil sprays.

- Crank shaft can be configured for multiple cylinders.

Sub-assembly Designs:

- Steam Engine Design/Bump Valve

- Steam Engine Design/Cylinder

- Steam Engine Design/Crank Shaft

- Steam Engine Design/Piston

Review Notes

Tom Kimmel of SACA

Some recommendations from Tom:

- Do more research.

- Come to my shop and look at real steam engines.

- Add teeth to the flywheel to allow an electric starter motor.

- Cylinder liners (sleeve) should be cast iron. Look into motor rebuild kits.

- Valves are not "chinese hat". Talk to Jay Carr about his design.

- Open or closed crank is a choice. Not critical.

- Lubrication is important, but had no specific recommendations.

- Start with conservative materials (like iron) and consider advanced materials later (like nitride coatings).

- Consider designing an exhaust manifold from the start.

- Visit Bill Ryan north of Chicago who has experience with making bash valves.

- Don't use stainless steel as a cylinder line.

- Consider 12v electric system for fans, solenoids, relays, water level sensors, and starter motor.