Large Workshop Structure: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

(→Links) |

||

| Line 51: | Line 51: | ||

*[[CNC Sawmill]] - also uses rebar trusses | *[[CNC Sawmill]] - also uses rebar trusses | ||

*[[Rebar Truss Design Guide]] | *[[Rebar Truss Design Guide]] | ||

=Related= | |||

*FreeCAD script for printing interconnectable beams? [https://3dprintingindustry.com/news/repraps-new-open-source-software-3d-prints-pla-beams-as-stiff-as-steel-194515/] | |||

Revision as of 03:48, 3 April 2023

Concept - Structural Space Frames

Build and Data Collection

Build Time

Logistics: 1 day weld, 6 welders, cutting happens prior to weld. 1 day assemble. Joints are required. Connector system must be created for this system if build is to be rapid. Choices include u-bolts and plates.

Working Doc 2

Part Library

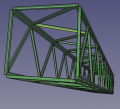

Workshop skeleton. - FreeCAD -File:Workshopskeleton.fcstd. Full file above 1 MB on gitlab - [1].

9 foot truss, 4-sided. - FreeCAD -File:9 foot column.fcstd

15 foot truss, 4-sided. - FreeCAD -File:15foottruss.fcstd

- Columntruss.png

8 foot truss, 4-sided. Double, used in columns. - FreeCAD -File:Columntruss.fcstd

8 foot truss, 4-sided. - FreeCAD -File:8footrebaruss.fcstd

12 foot truss, 4-sided. - FreeCAD -File:12footrebaruss.fcstd

3 foot truss. - FreeCAD -File:3foottruss.FCStd

Links

- Factor e Farm Improvements

- Large Covered Structure - initial hoop idea but flat hoops are not stable. Lesson: need to create stiff truss structures - triangular or square - to make the construction method robust.

- CNC Sawmill - also uses rebar trusses

- Rebar Truss Design Guide

Related

- FreeCAD script for printing interconnectable beams? [2]

![Workshop skeleton. - FreeCAD -File:Workshopskeleton.fcstd. Full file above 1 MB on gitlab - [1].](/images/thumb/c/c9/Workshopskleton.png/120px-Workshopskleton.png)