Universal CNC Axis: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 3: | Line 3: | ||

Larger axes will also be built, up to 2" for heavy duty CNC machining, with plastic parts sandwiched between metal plate as a plastic/metal composite structure. See calculations for beam deflection at [[Heavy_Duty_CNC_Construction_Set]]. | Larger axes will also be built, up to 2" for heavy duty CNC machining, with plastic parts sandwiched between metal plate as a plastic/metal composite structure. See calculations for beam deflection at [[Heavy_Duty_CNC_Construction_Set]]. | ||

=Concept= | |||

<iframe src="http://opensourceecology.org/3d-printer-construction-set-workshop/" height=500 width=1000 | |||

></iframe> | |||

=WebGL= | =WebGL= | ||

Revision as of 00:03, 7 February 2017

Intro

The following is a 5/16" or 8 mm version of the universal CNC axis described at http://opensourceecology.org/3d-printer-construction-set-workshop/

Larger axes will also be built, up to 2" for heavy duty CNC machining, with plastic parts sandwiched between metal plate as a plastic/metal composite structure. See calculations for beam deflection at Heavy_Duty_CNC_Construction_Set.

Concept

<iframe src="http://opensourceecology.org/3d-printer-construction-set-workshop/" height=500 width=1000 ></iframe>

WebGL

Working Document

- P1 - Visual Linked BOM (VLBOM)

- P2 - extruder stepper motor mounting

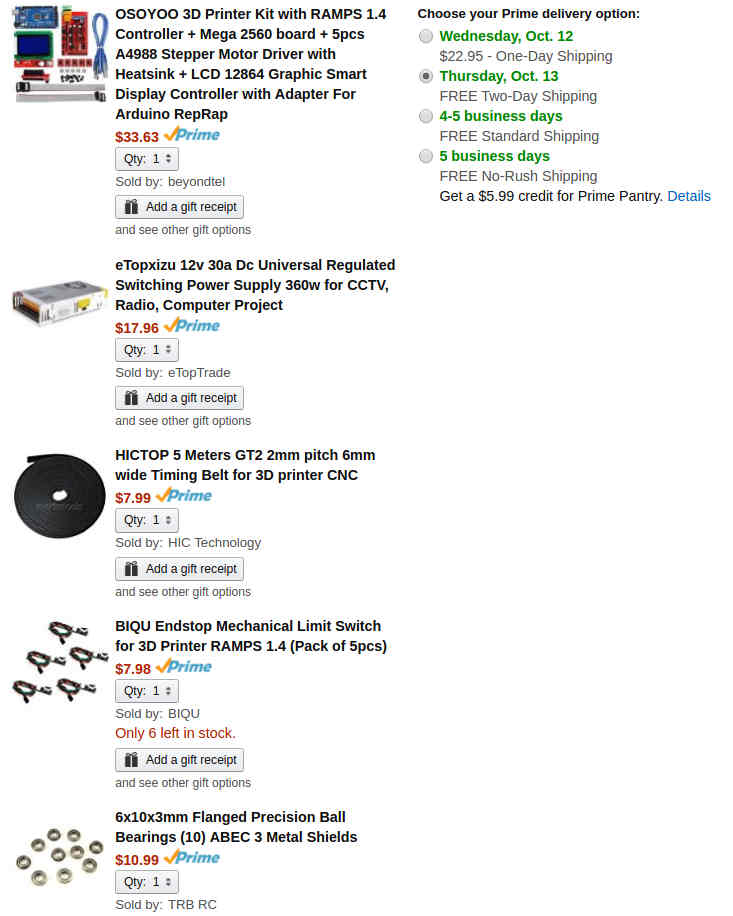

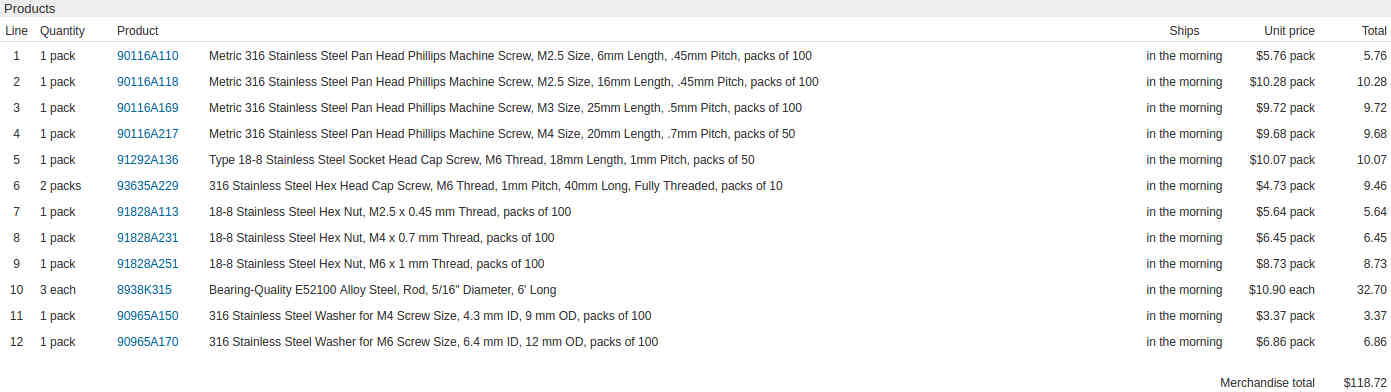

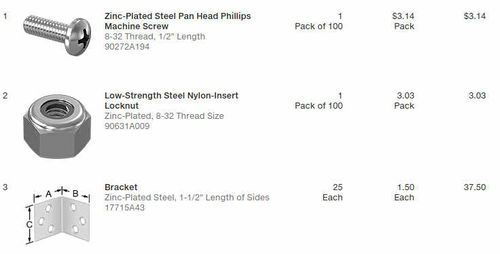

BOM

Order

Frame Parts

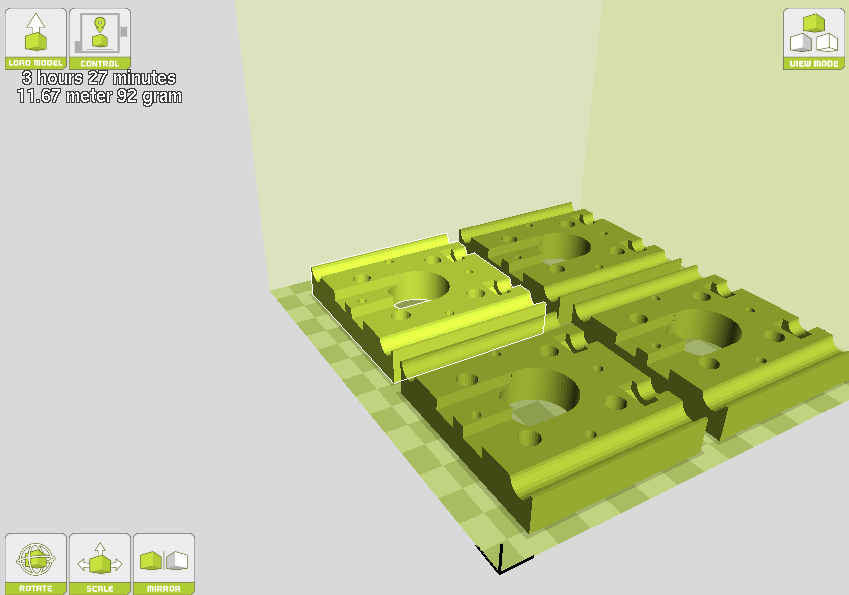

FreeCAD and STL Files for Printing

Fabrication

- Print time - 3hr27min for the idler end -

One Axis Attached to Frame

Links

- 3D Printer Design Evolution

- 3DP Construction Set workshops - December 2016 - [1]