Simple 3D Printer Extruder: Difference between revisions

(→Build) |

AbeAnderson (talk | contribs) (→CAD) |

||

| Line 16: | Line 16: | ||

=CAD= | =CAD= | ||

Turn this to a gallery: | *Turn this to a gallery: https://drive.google.com/drive/folders/1-2ASyEawm84AMfz3_cA3HgT0HBIJbDA6 | ||

https:// | *CAD & assemblies also @: https://gitlab.com/Abe_Anderson/d3d-mini-pvc/tree/master/Hardware/Simple%20Extruder | ||

<gallery perrow=6> | <gallery perrow=6> | ||

Revision as of 02:56, 28 September 2019

![]() Hint: This is a simple and basic low cost extruder for 1.75 mm filament that can be built from scratch. This is not necessarity optimized for rubber, and will not work with 3 mm filament in its basic form. This is an entry level extruder that can produce reliable prints, but is limited in filament size, will have slower rubber extrusion. Rubber Extruder is a 3mm extruder optimized for rubber, and also optimized for all other filaments.

Hint: This is a simple and basic low cost extruder for 1.75 mm filament that can be built from scratch. This is not necessarity optimized for rubber, and will not work with 3 mm filament in its basic form. This is an entry level extruder that can produce reliable prints, but is limited in filament size, will have slower rubber extrusion. Rubber Extruder is a 3mm extruder optimized for rubber, and also optimized for all other filaments.

Working Doc

Build

Pictures

Folder on Google - [1]

CAD

- Turn this to a gallery: https://drive.google.com/drive/folders/1-2ASyEawm84AMfz3_cA3HgT0HBIJbDA6

- CAD & assemblies also @: https://gitlab.com/Abe_Anderson/d3d-mini-pvc/tree/master/Hardware/Simple%20Extruder

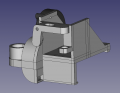

Simple Extruder Assembly - size:nullkb - FreeCAD -File:Simple Extruder Assembly.fcstd

Extruder Heater Block - size:nullkb - FreeCAD -File:Heaterblock.fcstd

Extruder Base Block - size:nullkb - FreeCAD -File:Baseblock.fcstd

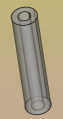

Extruder Filament throat and Heat Break - size:nullkb - FreeCAD -File:Heatbreak.fcstd

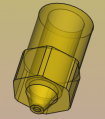

Nozzle - size:nullkb - FreeCAD -File:Simple extruder nozzle.fcstd

Spring - size:nullkb - FreeCAD -File:Simpleextruderspring.fcstd

Bearing Bracket - FreeCAD -File:Simpleextruderbearingbracket.fcstd. STL - File:Simpleextruderbearingbracket.stl

Spring Base Bracket - FreeCAD -File:Simpleextruderspringbasebracket.fcstd. STL - File:Simpleextruderspringbasebracket.stl

Reverse Engineering Pictures

Turn this to a gallery:

https://drive.google.com/drive/folders/1-2ASyEawm84AMfz3_cA3HgT0HBIJbDA6

Links

- Low cost 3D printer BOM - Simple 3D Printer BOM