Shonda Log

sespt 13

tack welded a few pieces, then finished what I could do on the Hydraulic coolers (ran out of parts)

|

| hydraulic pump |

I pulled apart one of the hydraulic pumps to see the internal structure, the housing parts are made from aluminum and look to be milled, the gears look ground, or just have a very fine finish pass, each of the two mounting blocks have thin brass bushing pressed into them, a gasket seal on the top an bottom plates and a radial seal on the shaft where it exits the pump.

assuming a lathe and versamil with NC control the housings, plates, and sleeve bearings could be made on demand, the gears I have to look into, but a grinding wheel that has been profiled with a diamond could be able to grind them to tolerance if needed. (diamond would be mounted on the collet for holding the gear and the lathe/mill could regrind the wheel when necessary (some testing will be required for determining hoe often the grinding will have to happen))

sept 12

here's a bunch of videos that I cam'ed on sunday, warning, they suck. but they show some of the development.

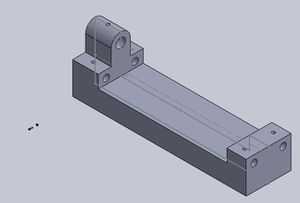

I also built the model for the MultiLathe, the first revision at least. [File:Lathe first run.JPG|thumb|pic]

vid of [Marcin] moving ythe hay cutter (mower?). yes it is flipped sideways, if you want it the correct direction post a comment on how to flip it, thanks.

sept 5

promises from last week:

- have a 6 month plan for the multimachine project (statues: failed)

- videos for the multimachine project (statues: have to escape them from the black hole)

- Wiki failed to upload Sep.2-3 on muffler

started design of a modified multimachine design, started with the sketchup model

promises for the next week

- model for the MultiLathe

- 6 month proposal skeleton

- dependencies

- videos on the multimachine

design considerations for the multiLathe

- retrofit-ability for CNC

- threading

- main drive (Z-axis), leadscrew or Rack and pinion

- flat slide or round ways for cross slide

- proof of strait way production [Multimachine/Research Development]

Positives:

- Threaded engines

- Cutting of stock for Power Cube

- Grinding for Briana

- Documented track fab

- Drilled all mufflers

ground hopper/shaker motor supports for [Brianna Log]

Promises for week:

- Full frame CAD for Lathe Bed

- Post to Open Pario on a daily basis

- Module list for multimachine project: rotary table, versamil, indexing head, fast spindle, slow spindle, ways, CNC retrofit, toolpost, cross slide, CNC toolchange spindle 40 with air pressure, surface grinder, fly cutting, threading, tap-and-die grinding, possibly cold cut saw, blade manufacturing, ballbearing grinder

- Publish a video describing the modules

surface grinding that i did back at dunwoody. it takes about 1-5 minutes to get a part onto the table and dogs set. the surface of the CEB draws, top, 2 blades, and sides, could be done in 30 minutes to an hour each.

videos of lathe and milling

sept 1

- Threaded engine mounts:

- talked with Bruce most of the morning, possibility of connecting organizations and contacts

- shopping for food

Bruce here through friday not sure how much work I can get done

Aug 31

tried out 123d. verdict: buggy and not yet fully realized, has useful features (sketches w/ constraints, sweeps and revolves etc.) but they are still very hard to use. I wish I had Solidworks, we'll see.

unsure how much work I will be getting done until Saturday, as Bruce will be visiting.

drilling muffler pipe, we have 10 small pipes with 36 1/4" holes

cut

Aug 30

- removed plate from CEB fro rewelding and grinding (also forced nuts onto two plates)

- cut last of stock for Power cubes

- ground CEB press cavity? square

Aug 29

cut angle for the power cubes 1 24”, 2 27”, 4 29”, 8 4.5”, and 4 8” left

ran ad-hoc operations for Briana

found out that the track welding jig was sized for different chain gauge

Aug28

editor and slow internet ate this post

Aug 27

editor and slow internet ate this post

aug 26

- started fleshing out tool dependency for multimachine and related projects. Shonda_Research

- published about 200 track sections

- should do a large drawing (semi promise)

- marked out locations to weld bolts, will have to grind off because to much hang over. increasing bearing distance (not that great of a solution and I can only move it 1.5 inches in further but better then the hang over that I had.)

aug 25

- pinned coupler to drive shaft for lathe, drilled out set screw land, marked out size to torch back bearing plate.

- researched and conversed with multimachine yahoo group

aug 24 2011

- I have been looking through the documentation for the new multimachine lathe and have been trying to up-size it and increase the robustness of the design.

the basic idea is to build a lathe from concrete and round pipe, aligning everything with setscrews and non-shrinking grout. In places without machine shops the lathe can boot strap itself with car parts scroungable from a junk yard.

as we are trying to increase production speed of the prototype I am looking at sourcing major components from outside machiniest, namely the rails (which we could harden and grind with a centerless grinder and induction furnace), and components for the cross slide and tailstock, which will probably be farmed out to sweiger if they have the equipment or a shop in st Josephs. All alignment and casting of the machine will be done onsite however.

currently using L Yoeman's style of concrete and round way machine tools the only imperative tooling is a centerless grinder for making the rails round and strait.

- tolerences of industrial equipment

"Lengths up to 55'

Diameter tolerances to .0002 in

Surface finishes to 4 micro inch." source http://www.centerlessgrind.com

- A vitrified grinding wheel has a max RPM or 3600 generally, a 4000 RPM spindle is fairly easy to make if you can purchase bearing and turn a housing (probably want seals to if its for grinding)

http://groups.yahoo.com/group/multimachine/message/14722

aug 23

got up at 8 so only 4 hours sleep.

tightened wheels on new millermatic.

wood gasifier open source kit [[1]]

horizontal milling machine in previous post not going to work machine is built for facing pieces not tool room work the z axis has about 2 1/2in of travel rather then 12 or more inches that would be useful, also most of the controls are hydraulic with dogs rather then hand cranks.

multimachine groups lathe animation[[2]] shaft fitting bearing plates still need to weld set screw nut on will mark location on.

going to be helping Briana with punching CEB piston holder holes.

promise: 6 month plan for the Multimachine project by 8/25/11

Looked through yahoo Multimachine groups lathe documentation[[3]]. 2 hours. I think they are still missing documentation on lots of theings but they have an open review where people will be asking questions and filling that stuff in ... I'm going to use this as the basis for our lathe project. using hardened and ground shafting rather then scrap pipe, and using a half round slides, that can be bored on a lathe, on the round ways rather then angle Iron and brass wear strips.

other thoughts: add mounting bolts for quick change gearbox (to be added after the lathe is running). bolt down second cross slide plate to first from the bottom. move z axis hand wheel from between ways to side of cross slide using sprocket and chain. flip hub on threading attachment so that sprockets could be quickly changed(maybe, might be more trouble then its worth..

aug 22

internet was out in the morining, it apears that mice use the power switch as a foot hold for getting to the ceiling

revived message from multimachine group (log in Multimachine/Research Development)

worked on lathe motor mounting plate holes were offset. still need to weld 4by4 pipe and motor quick attach plate on. possible difficulty, coupler for motor and 1 7/8 shaft.

helped adam with box blading new workshops site. boxblade quick attach plate started breaking apart and we had to torch bolts off since they were bent then weld a new plate with smaller hole so that the blade wont rip out of the quick attach holder.

spent a 3 hours box blading the site then the second bolt plate ripped out and we brought the tractor back.

my power cord for my computer should be at the post office as of this morning

put up eves on shed roof with adam

found this horizontal milling machine [[4]]

picture from Adam_Log and Tom_Log

put up roofing with Marcin and Briana until 3:30 AM

aug 21

researched concrete machine tools - result - multimachine group is closer then I origenaly thought to releasing designs for a lathe design

helped Adam unstick tractor from second entry way and then moved wood from the chestnut tree to chip pile and wood pile. put up one level line for the workshop.