Colten Jackson Log

Jump to navigation

Jump to search

March 13

3D Soil Mixer Model continued

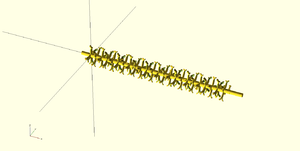

- Used the CAM Files Protocol to get an STL file from the Sketchup file Ben developed (Thanks Wes!). Here's the original sketchup: BenSoilMixer.skp And the resulting STL: BenSoilMixeruntitled.stl

- I opened the file in Blender and made several alterations to make the object more printable. The Sketchup file represents how the bucket will look when constructed out of steel, but in making a miniature out of plastic I thought it was prudent to make it easy to print in one piece. Mostly, I thickened the walls and made the teeth slope out of the bucket so that the whole thing will print without supports. I also altered the pulverizer-axle-holes to a 'tear drop' shape that will print more accurately than a circle.

- I then uploaded that STL to NetFabb Cloud Service to repair the file. Here's the fixed file resulting from that, ready to be sliced: File:Printablebucketthickenedwalls fixed.stl

- Researched slicer options, looked at Cura, Slic3r, and G Replicator. Really impressed with this tutorial but I have a lot to learn. Since I'm already familiar with Cura, I set up a new machine in its settings and copied all the parameters from the Lulzbot Taz Slic3r Profile for medium speed, ABS plastic, and .35 mm nozzle.

- Here's the Cura configuration file. It could use more tinkering, but it's quite functional. File:Cura TAZ ABS 35.ini

March 12

Soil Mixer / Pulverizer: 3D Printed Model

- Downloaded and watched the pulverizer prototype videos ( one, two, three ) to become more familiarized with the construction of these things.

- Intended to help Anthony flesh out preliminary build instructions, but felt totally over my head. I don't know the first thing about machining!

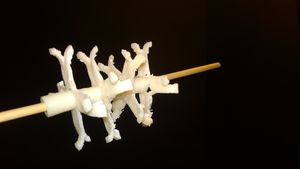

- Decided to collab with Eric to get a 3D Printed model going. He just had to modify the OpenSCAD to make the object a bit more printable. Decided to omit the 'bolts/nuts' in the 3D Print, thinking we might just use real (tiny) screws to secure it.

- Scaled the model down to fit over a common wood skewer, 4mm diameter.

- Uploaded the stl so you can print your own: File:Singletine6mm.stl

- Printed out a few of these. I intend to print enough to make a complete model. They take about 12 minutes each to print, plus a little clean up work with pliers, craft knife, and ABS glue.

Plastering

- Helped with the work of re-plastering portions of the wall that cracked due to improper application.

- Took a stiff broom to cracking portions of plaster that didn't stick, knocking off anything that had an edge to catch.

- Found that even portions of the wall that weren't obviously cracked had developed micro-cracks and would come loose in chunks when applying fresh plaster over it. Andrew made a video documenting this.

March 11

Morning Design

- Soil Pulverizer design team was struggling with importing the file created in OpenSCAD. The STL file contained only a couple of rectangles, didn't include the grid-beams that were rendered within OpenSCAD.

- Researched import/export options to use files from OpenSCAD, found that the program is too "fastidious" with STLs, it only exports solid objects. If for any reason OpenSCAD doesn't consider a volume to be solid, it won't export those shapes.

- Eric made slight changes to the OpenSCAD file to ensure it was a solid shape, was then able to export as STL. He explains this process here: OpenSCAD#Collaboration

HabLab & Mircohouse

- Went outside to help prepare the south side of the HabLab for trimming the windows. Knocked off plaster so trim would sit flush. Sanded window frames.

- Assisted Wes in bringing the steel window-replacement down to the ground.

- Checked in on the Microhouse, took a couple of panoramas.

- Learned how to mix up some mud to apply to the walls.

- Learned how to nail & staple chicken wire to CEB walls.

3D Printer refab

- Opened the Ultimaker Mechanical Guide to learn how the extrusion head goes together. When I arrived at HabLab the extrusion head was disassembled, all the screws taken out, but all the parts were laying right below it so it looked like it would be easy enough to put it back together.

- Discovered that the filament in the 'feeding tube' was completely clogged - not the extrusion head - the 3D printer filament was stuck inside the feeding tube - I couldn't get it to budge. I don't understand how this could have happened.

- Also discovered that the Ultimaker is a pain in the neck to unclog: you have to completely disassemble the extrusion head and the extrusion motor mount (on the back of the machine) to remove the feeder tube. I did so. Wes was able to grab the bit of plastic from the end of the tube and pull, but it took some muscle. Epic work!-MJ

- With the plastic out of the way, I followed Ultimaker's documentation to reassemble everything.

- Used the onboard controller to test that the motors work. X Y and Z. Couldn't find a way to test the extrusion motor.

- Hooked the machine up via USB to my laptop, set up Cura, Ultimaker's slicer and printer controller and walked through its initialization. Set up using defaults for "Original Ultimaker" - it recommended upgrading to the Marlin firmware, and I did. Supposedly, it improves prints through 'looking ahead' in the gcode and controlling acceleration.

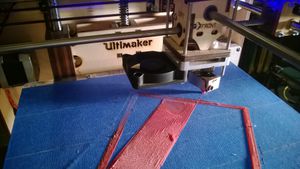

- Checked all 6 endstops to progress through Cura's setup process. It then recommended going through the bed leveling process with a test print, just a simple square around the perimeter of the print bed. I clicked 'Go' and the printer started making stuttering and binding sounds out of the stepper motor, so I cut the power.

- I was perturbed and confused by the binding sound - I'd only heard it before when accidentally telling the motors to drive into a wall. (Binding as it tries to push against a wall). When I tested the x, y, and z motion, there wasn't this kind of sound.

- Ultimaker can print files off its SD card. There were some files on here so I decided to try printing one of those, thinking the printer knows itself better than Cura.

- The print went smoothly, none of the stuttering I'm-Destroying-Myself sounds.

- Will have to tinker more with controlling this with a PC.

March 10

- Participated in first design session of the week, doing preliminary sketches and dimensions for a soil pulverizer and mixer.

- Mostly noted the process issues: the group spent a lot of time trying to connect to the wi-fi, exchanging log-in information for different websites where resources were stored, having to ask where such-and-such file was.

- Chatted with Ben about how much better it could be if we had a local shared drive to store currently-in-use files and a local install of a collaborative doc editor such as Etherpad so we wouldn't rely on the ISP to access our documents.

- Looked up a way to synchronize a local clone of an entire wiki: WikiSync Would probably have to totally rework a lot of stuff (some of the wiki takes info from google docs. Would be really difficult to replicate certain functionality with a locally synchornized system.) Considering that replicate-ability is a major tenant of the Global Village Construction Set, and that so many places don't have reliable internet access (including rural Missouri), it would be of great benefit to figure out how to do collaborative design work without internet access.

- Learned how to sling a 'mud stucco' at the Microhouse.

- Got the Lulzbot A0 101 up and running. It was set up and ready to go, just needed its bed leveled.