Large Workshop Structure

Purpose

Rebar is the most widely available structural component that can produce a wide range of structures - with 1 part material count. Rebar-based space frames are a robust way to execute roofs, columns, platforms, towers, frames, building structures, and other structures in a highly Degenerate context. Further, rebar production can be attained from scrap steel and a solar PV induction furnace, meaning that the cost structure would be disruptively inexpensive. If a shredder + induction furnace were available, where aluminum windings for engine-driven generators can be had, then advanced civilization (steel wielding civilization) can be attained from dirt and twigs. With the Charcoal Combine or PV providing electricity, abundance can be generated readily by providing the structures and steel of modern living.

Thus, mastering the design of Frames is important, and the rebar-based space frame is essential to this goal. Further, the concept can be generalized to ships, drums, towers, rotary kilns, etc. Let's explore the limits at Space Frames.

Product Ecology

- Integrated with CEB, concrete, and standard framing to allow for 3 dimensional scalability.

- Allows for exoskeleton addition and Extensive Scalability from the outside

- Allows concrete fill, added columns, added trusses inside.

- Allows Hybrid Scalability for internal rebar trusses.

- Allows for Roof First builds for CEB infill.

- Allows for earth augers and hybrid concrete- earth auger structure.

- Allows post-finishing of floors by compaction, concrete, other surface

Concept - Structural Space Frames

Details

- Extensive and Intensive scalability of indidvidual columns via size: LWH, and size of rebar

- Hollow core (tubular) also means that we can scale by internal superposition of modules

- Retrofittable concrete pillars - Example: 12" base structure, insert a 6" core with concrete for retrofitable vertical scalability of structures

- Insertion is possible from the top from a hatch in the roof. If using flat roofs, vertical stackability is high.

- In fact, all columns can be inserted, 2nd floor could be jacked up as a whole using the first roof and simple jacks at each post. Posts are pinned as they are jacked - crushing safety is guaranteed.

- 6x6 inch column can be grown on 1 acre of farm (see Farm Yields Per Acre) (400 kg/hr) - 10' of height =2.5 cu ft -> in 6 minutes. For 20 columns - 2 hrs of farm crop from an acre.

Build and Data Collection

Build Time

Logistics: 1 day weld, 6 welders, cutting happens prior to weld. 1 day assemble. Joints are required. Connector system must be created for this system if build is to be rapid. Choices include u-bolts and plates.

Material Cost

- 20'x20' - 9.6 sticks at $6.5 [2] for 130 lb truss. $63 per truss.

- 20' cube costs $756 for the structure. 12 truss.

- 20' structure- Let's keep it sane - 10' ceilings - and 10 truss equivalent. $630. Keep it to 20x20 units that can be added on.

- For 8x20 structures such as trailers (13.5' max) - 144' of truss or about 7 truss equivalent. 900 lb frame.

- 8x10' structure for trailers - 5 truss equivalent or 650 lb, $300 in frame materials.

Working Doc 2 - Build Instructions for a Large Workshop Foundation

Part Library

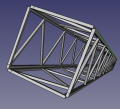

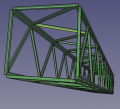

Workshop skeleton. - FreeCAD -File:Workshopskeleton.fcstd. Full file above 1 MB on gitlab - [1].

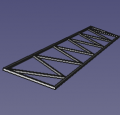

9 foot truss, 4-sided. - FreeCAD -File:9 foot column.fcstd

15 foot truss, 4-sided. - FreeCAD -File:15foottruss.fcstd

- Columntruss.png

8 foot truss, 4-sided. Double, used in columns. - FreeCAD -File:Columntruss.fcstd

8 foot truss, 4-sided. - FreeCAD -File:8footrebaruss.fcstd

12 foot truss, 4-sided. - FreeCAD -File:12footrebaruss.fcstd

3 foot truss. - FreeCAD -File:3foottruss.FCStd

Industry Standards

- See what coupling mechanisms for large concert trusses are - [3]

Links

- Space Frames

- Factor e Farm Improvements

- Large Covered Structure - initial hoop idea but flat hoops are not stable. Lesson: need to create stiff truss structures - triangular or square - to make the construction method robust.

- CNC Sawmill - also uses rebar trusses

- Rebar Truss Design Guide

Related

- FreeCAD script for printing interconnectable beams? [4]

![Workshop skeleton. - FreeCAD -File:Workshopskeleton.fcstd. Full file above 1 MB on gitlab - [1].](/images/thumb/c/c9/Workshopskleton.png/120px-Workshopskleton.png)