Edge of Knowledge

![]() Hint: Here we derive by one argument that Humanity's kernel of practical knowhow is estimated to be worth $50B based on the value of global product R&D over one patent cycle. Initially called Knowledge Kernel, this is perhaps better called Knowhow Kernel. This is achievable at the proverbial 1/10th a cup of coffee.

Hint: Here we derive by one argument that Humanity's kernel of practical knowhow is estimated to be worth $50B based on the value of global product R&D over one patent cycle. Initially called Knowledge Kernel, this is perhaps better called Knowhow Kernel. This is achievable at the proverbial 1/10th a cup of coffee.

About

The edge of knowledge is simply the limits of human knowledge.

The point of this distinction is to raise awareness that the edge of knowledge is near, in the sense that any individual who goes deep into any pursuit of knowledge will quickly recognize that there are unanswered questions. In fact, an astute observer will realize that there are more unanswered questions than knowns - once the individual begins to probe further in breadth and depth. This questioning can be used to delve deeper into any concept, such as, 'is the earth flat' or 'how do you make a more efficient bearing' - and to complex questions, such as 'how to end class war.'

OSE Approach

In the Future Builders Academy apprenticeship - we teach the limits of knowledge across all areas and disciplines of human endeavor. What one finds out is that very quickly we arrive at areas which have no solution, including obvious ones: why are so many people in poverty? Why is there war? These are concrete questions that require divergent solutions. Along with obvious questions, there are known capacities - but we must study them for what is possible in human and natural performance specifications.

. [1]

. [1]

Meta

The most powerful gift that keeps giving - is when one figures out their calling in life - and pursues that without limits. Few people discover this. In advanced civilization, discovering this early on should be the norm. One of OSE's goals is to normalize the funding of such meaning by the time one reaches around 18-24 years of age. The OSE Apprenticeship is an adventure designed to make finding one's calling while one is embedded in a rapid learning environment where apprentices learn how to learn, learn how to think, and learn how to truly collaborate.

The exposure we aim for is to learn everything about everything and to build anything imaginable - with the only constant being meaningful engagement. Since this is impossible, we can aim for learning The Edge of Knowledge through a survey of all human enterprise, and to build just about anything by learning Universal Design.

Aspects of the Edge of Knowledge

OSE believes that we can study the edge of knowledge formally to attain increased understanding more rapidly, such that we form accurate mental models of reality. Such understanding is critical for human progress, and is at the core of the 'good old fight of good versus evil.'

The process for studying the edge of knowledge may include:

- Scope is every discipline (tech, society, and humanity)

- Learn the seminal thinkers (mostly dead people) who took the world to its current state across all discipline. The goal is to identify readily - the current state of thought in any discipline . This is a basis for knowing what is important in the world, and what is noise, from the perspective of moving humanity forward. This is under the assumption that we can make a better world, and any sentient being should think about this topic at least some of their time on this planet. This is called Time-binding.

- Learn a broad scope of practical knowhow in Rapid Learning Facilities, which also span every discipline.

- Educate oneself broadly, specializing in generalization - but if one can learn at least 10x more than by usual means - then one can indeed 'specialize' in 10 disciplines at the least, meaning one has become a renaissance-like generalist now capable of solving real global issues. This could cure The Best and the Brightest, while mixing class by leveling the playing field so that anyone from any background can remove former glass ceilings by virtue of Life-Work Integration.

About

- 1000 Hour Curriculum is the base promise of OSE to take anyone to the limit of human knowledge across all disciplines in 4 years by Integrated Learning

- Class room is not just a plain class room - but a lab with hands-on build, computer design + collab, virtual augment in lab, or school without walls. In fact, it is the Rapid Learning Facility of 24 to 50 bays at core. Think about how to apply RLF to other organizations outside of tech: definitely ag, but what about economics, governance, culture, spirituality, art, interior design, hardscape, waterscape, soil, rocks, wood, plastic, semiconductors, food, leadership, mind-body practice, business development etc. Extend RLF to all these sectors

- RLF is base for any sustainable community. Thus, rollout is RLF to housing + ag, to manufacturing, to village bank to R&D on Civilization Integration.. Access is controlled by transparent credentialing with continuing education. Start is Values (moral intelligence, no assholes) + learning How To Learn

- About $6M for 1000 Hour Curriculum dev. Essentially around 50 GVCS in cluster areas

- Basic specification is presented, technical writers and engineers are hired to produce understandable materials

- Getting is the ability to follow a specification or to help refine it

- Add 100% off-grid capacity to Savannah

- OSE Social Contract is Moral Intelligence, genius (learning how to learn), abundance, and open collaboration. We expose the genius in everyone - our 4 year program is for elites and the downtrodden willing to rise

- Curriculum is inserted into every Tech School, college, and University worldwide, starting with. Native American colleges.

- MJ is headmastér and teacher initially. Part of process is getting to the Edge of knowledge in all disciplines myself

- It is about building a community for swarm builds, Civilization Rebuilding, continuing development. Addresses The College Gap.

Approach

To reach the edge of knowledge and regenerate one's genius, our approach for each lesson in the 1000 hour curriculum is to study:

- History of the topic

- Broad patterns, principles, seminal work, and status quo of the area

- How the topic relates to all other areas of human endeavor

- How the topic has changed over time and space

- Points of possible improvement and transformation

- Integrated strategies that emerge based on all the prior items above

Teaching Challenge

Human knowledge has become so specialized that the top experts know very little about how their area relates to other disciplines, institutions, or sectors in in the world. Such fragmentation is a serious threat to the democratic process, because it is difficult for people to attain accurate mental models of reality. This leads to political manipulation, financial insecurity stemming from an unlevel playing field, a scarcity mindset stemming from under-appreciation of human and natural resources, and a general lack of autonomy self self-determination.

The current fragmented nature of human knowledge makes it difficult to find single instructors who can cover all the relevant topics in each of the thousand lessons. In particular, most experts know very little about topics other than their focus. Since OSE is pursuing integrated education, integrated design, and integrated enterprise - this can be solved by a survey approach in which a number of key instructors are brought in for the main topics in each area.

The bottleneck naturally becomes the curriculum integrators - who would need to have a lot of the relevant knowledge already when designing the curriculum. Because our scope is so comprehensive, this remains a daunting task. The key to success is defining a generic, skeletal curriculum structure - which can guide curriculum design - as a general pattern through each of the thousand lessons.

The resulting curriculum must allow both for sipping and gulping from a fire hose of knowledge, depending on one's prior education and experience. The curriculum must be of sufficient quality to allow both novices and experts to be able to benefit. Best practices of pedagogy must be used such that the learner can either skim or survey the material, or go in depth as far as needed to grasp seminal concepts.

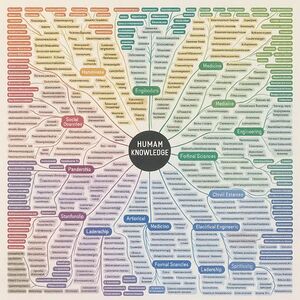

If we claim that there are 8 [2] broad areas of human knowledge, see diagram. Since the full curriculum allows for thorough redesign of civilization, it follows that the curriculum must make all economic design and process transparent.

Cost to Open Source All of Technology

How much is all the underlying knowledge worth? Ie, how do we run government, educate people, make microchips, or split atoms? One (limited) way to calculate this is the difference in economic output between today and 19 years ago, the time for patents to run out. It may be said that the difference, adjusted for population growth, may be due to 'innovation'. Thus, this difference is the value of all economically significant knowledge - Value of Knowledge or VoK.

The notion above relies on the assumption that all knowledge older than 19 years is freely available. This is of course not true, as trade secrets are lost because they are not published openly, thus all past knowledge is effectively lost. There is a double dilemma: older knowledge is not available, and current 'best practice' is all proprietary. This is the unfortunate big picture of global knowhow, which implies a very uneven playing field because new economic players are effectively prevented from entering the playing field.

The VoK number must be lowered by the percentage that typical companies spend on R&D - or innovation. That percentage is only 1% - see R&D Budgets. There is also a large redundancy in the knowledge, ie - likely a number N = 10 companies or organizations work in each field of endeavor without sharing knowhow, without collaborating. Thus it can be said that the actual knowledge kernel is N = 10x smaller. N can be likened to 'reinventing the wheel factor'.

In summary: all increase of GDP worldwide over 19 years is assumed to be the result of 'new knowledge' (adjusted for population growth) - ie, this knowledge is assumed to be responsible for the increase in GDP (otherwise GDP would be the same if no innovation occurred, if discounted for population growth). Therefore, the cost of all this new knowledge (cost of all of civilization's knowledge) is:

Cost of Knowledge Kernel = KK = GDP growth in 19 years * R&D% / N

Cost to Open Up Education

![]() Hint: The cost of the overall kernel of human global economic knowhow is defined as the Knowledge Kernel (KK) above

Hint: The cost of the overall kernel of human global economic knowhow is defined as the Knowledge Kernel (KK) above

.

True education would mean adding economically significant knowledge to the typical theoretical curricula of colleges. The assumption here is that education produces economically significant knowhow. Currently, education systems are biased towards creating servo-mechanisms that perpetuate the status quo. However, we propose entrepreneurial, startup culture - which is a clear Affordance of a playing field in which access to economically-significant knowledge - with its attendant culture of transparency and collaboration - is open and is taught in universities. Unless this option is created, we are likely doomed to a permanent culture of scarcity.

Realistish Numbers

Let's attach real numbers to this transition.

The actual numbers for global GDP are 39T in 2003 and 105T in 2023 - about 65T increase. Population is not a great factor - 8/6.4 Billion => 25% increase. Thus population adjusted productivity increase is about 50 trillion. If there are nominally 10 companies worldwide per product, and R&D is 1%, then KK, the global knowledge kernel, costs $50B by the above discussion:

KK=$50T * 1% / 10 = $50B

Reality Check

Can all human knowhow cost only $50B if one fighter jet development program costs more than this?

Is this consistent with the fact that the F35 jet - by itself and out of many hundreds of other multibillion dollar programs that generate no shared value - costs $12B annually in R&D [3]? Yes. The explanation is that such programs simply do not contribute to essential productive value, but are instead one of the numerous costs of competitive waste. On one side, cost could be lowered at least 10x with open source, collaborative military R&D. And more fundamentally, it is worth investing in civilization redesign where competitive waste is eliminated all together.

Thus the cost to Open Up Education - so that every economic actor, company, or institution functions at their peak of knowhow - is roughly $50B, one time. This is the price of the combined USA cup of coffee per year, and less than 1/10th the cost of a cup of coffee the world over [4]. From the initial outlay, it is the goal that open culture perpetuates the creation of open knowhow. Furthermore, a significant multiplier effect comes into play once best practice is shared across industries. The possibility of a maker, entrepreneurial civilization enters, possibly shifting civilization to general financial independence and an end of consumerism and war.