AbeAnd Log: Difference between revisions

AbeAnderson (talk | contribs) mNo edit summary |

AbeAnderson (talk | contribs) |

||

| Line 18: | Line 18: | ||

Downloaded September or October? OSE version of Marlin. Reading up on it on their website. Inkscape Gcode tools extension also says there is an update availvable, but I'd hate to get into new version issues. | Downloaded September or October? OSE version of Marlin. Reading up on it on their website. Inkscape Gcode tools extension also says there is an update availvable, but I'd hate to get into new version issues. | ||

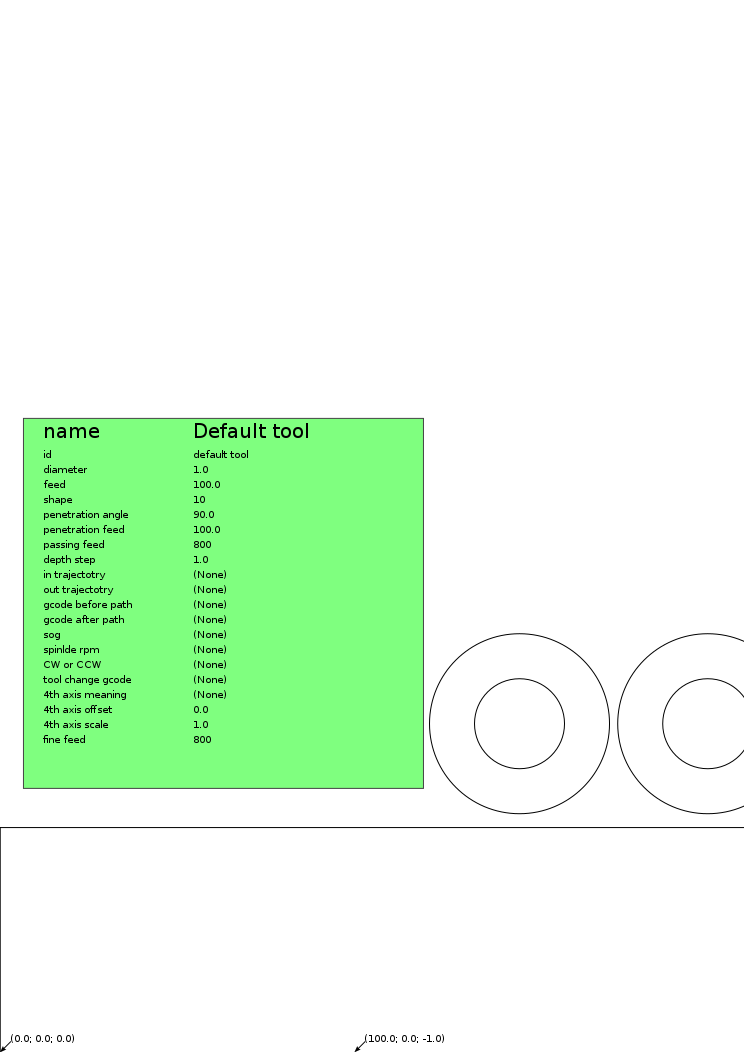

The green thing , but I don't know enough details about Marlin | The green thing settings for plasma might be similar to gas torch, but I don't know enough details about Gcode Marlin toolchain yet. | ||

=Sat Oct 14, 2017= | =Sat Oct 14, 2017= | ||

Revision as of 16:18, 15 October 2017

General links Critical Path Roadmap HR mediawiki formatting help Development Team Log Volunteer Timesheet OSE Hangout OSE Jitsi Meet

Abe's Links Abe's OSE Google Drive Folder Abe's OSE Google Calendar Abe's YouTube channel

'Current Logs'

Sun Oct 15, 2017

Downloaded September or October? OSE version of Marlin. Reading up on it on their website. Inkscape Gcode tools extension also says there is an update availvable, but I'd hate to get into new version issues.

The green thing settings for plasma might be similar to gas torch, but I don't know enough details about Gcode Marlin toolchain yet.

Sat Oct 14, 2017

Looking for torch table software tool chain info. I see a spreadsheet that is dated older, but references a switch to arduino reprap style software. I expect it is similar to other D3D machines. The torch table software details may not be refined yet so I went back to the microtractor part details and updated the track parts so the position of the track and asociated parts can be refined.

I am now tracing the track path around the components in the master cad to refine its shape. Rotating the track unit compound relative to the sketch plane seemed to get the track pads aligned out correctly. This can be confusing, but the freecad documentation does explain this. Further forum searches and reading suggests changing the center or origin point of the part may make a difference. Making the sketch line segments more detailed and aligned around the sprocket just right should give a good track eventually.

updated track CS with reference parts from the master CAD. Close at least the position relative to the idlers is ok. Adjusting the position of the track unit compound relative to origin should make it rotate tangent to the sketch and fit the sprocket better. Now at least the distance needed to clear the arms can be checked.

I just remembered I need to reset the track link spacing to 0.8" for the 3/4" sprocket.

Fri Oct 13, 2017

Installed FreeCAD 0.17 and tested the SVG Export. FreeCAD 0.17 managed to export the SVG more completely except the curves and circles are now lines and polygons. I think I read there was setting to change, but I can't find it now.

Exported DXF's and copied parts together into a single file for track unit torch test. LibreCAD is buggy even at basic copy and paste. Actions repeatedly crashed unexpectedly or simply failed to work with consistency.

Opened DXF's in Inkscape attempted to setup G-code. I'm not exactly sure what settings should be for CNC torch table. More research needed.

It also appears it is not generating G-code because the lines need to be converted to paths.

Tues Oct 10, 2017

Made a video showing the inconsistencies in SVG output.

I also posted a query to the freecad forum.

https://forum.freecadweb.org/viewtopic.php?f=8&t=24831

Meeting clarified re-use of previous drive sprocket with 3/4" plate and possible design solutions for the track tension.

The box around the upright tubing method using 1" bolt is simple. Need to consider the position of bolt hole relative to frame tube holes. It'd be nice to design in an easy method to apply leverage to the box against the frame to add tension while tightening the bolt with an impact driver and so one person can do so safely.

Track units need 3/4"+ spacing between links. So the new track unit file needs re-adjusted.

DXF to G-Code in Inkscape

https://www.norwegiancreations.com/2015/08/an-intro-to-g-code-and-how-to-generate-it-using-inkscape/

I also see http://opensourceecology.org/wiki/DXF_to_G-code_Conversion_Tutorial

https://www.youtube.com/watch?v=4jYKMAjzK3A

I also assume I need to brush up on LibreCAD for editing the DXF's.

Got a response on freecad forums suggesting 0.17 will work better then I realized I also failed to read all the way through the thread and there are more instructions on using Inkscape to fix the SVG's. Looks like a few more steps, but it should be worth it.

Mon Oct 9, 2017

After having worked with and looked at the SVG's generated by Freecad and a comment I see on jack.works I don't see how this will work directly from FreeCAD drawing SVG's. The SVG's are made of broken independent line segments and not continuous shapes and they need to be for the software to work. So evaluating the software that generates the SVG's in FreeCAD may lead to a solution long term. Other conversion routes like DXF to SVG using another app OpenSCAD or any other open source tools. Given this is a valuable open source project may be more interest can be found for recoding FreeCAD for compatibility.

SVGNest also appears to have a number of bugs and issues with types of lines. The question is whether further development can fix these easily or they can be worked around with minimal user effort https://qcad.org/rsforum/viewtopic.php?t=4334

There is recent ongoing work on a nester in FreeCAD, but it is alpha software and still missing needed capabilities.

https://forum.freecadweb.org/viewtopic.php?t=23484

I also found some other test SVG files on freecad forums when I uploaded to svgnest they appeared incorrect probably due to arcs and splines.

Thought I might be doing something wrong with the freecad SVG export since others on the forums suggest svgnest. So I followed instructions to use 2dview first then export to flattened SVG. This appears much better and would probably work except that it left out the holes in middle of the part. The 2dView shows the part correct, but not in the SVG. I'll try some more parts just to see how buggy it is.

I exported a 2DView of a 4'x8' sheet and the PTO motor mount which appears correct, so I created a layout of copies in a single file. The scale did appear ok. When trying to select the bin in svgnest however it still selects seperate segments of the bin and every other part instead of the whole rectangle for the bin. I assume this means the parts are not made of continuous lines such that is can identify them as a single component. I am saving the file as a plain SVG instead of the inkscape format in case this causes any issues.

Sun Oct 8, 2017

With reworking the track units from the basic sketches up I found some of the details were different for previous builds or files were just unfinished. I'm trying to make the CAD accurate enough that with metadata it is effective for more of the documentation.

There is a variety of different documentation and examples of track discussion so there are a few small things I am unsure of.

I see previously washers were welded on rods and drilled for cotter pins, but I think I recall a discussion in a meeting recently suggesting bolts worked better, but cost more depending on size and grade obviously. The current CAD looks like a rod with washers on both ends. What design is planned to use for this build?

Also since 1/2" plate is being used compared to 3/4" before the gap between the links has to be narrower to minimize the roller play. I am guessing this could make certain welding methods harder. I set it about ~0.6" in the current CAD. Obviously, this affects pin length as well. I'm assuming there should be at least an 1/8" of play in the pin.

I'm moving on to solving the nesting today so I can evaluate that and report a strategy for the next meeting. There appear to be many parts and assemblies made from 1/2" sheets. There must be DXF's for many of these from previous builds so I will search for those for testing. The first step is defining a clear process and making a how-to video.

Considering there are so many assemblies to break down and convert the best method may be sprints so work can be divided in parallel. Experimentation with all the parts in one nesting may help determine certain patterns. Obviously, multiple sheets are required, but given the mix of geometries, it is not safe to assume ideal part mixtures for packing order. Rounding off more corners on parts may increase packing given all the circular parts. Some small parts could be nested inside other waste parts, but that requires hand optimization of DXF/SVG and order of operations through gcode or however the torch table code chain works.

Looking at svgnest further it has options for part in part and concave search likely needed for parts like the sprocket. 3/16" spacing =~ 13 pixels assuming the software exports based on 72dpi. Inkscape appears to easily import and save between SVG/DXF. Batch capability would be great. I see some other extensions as well

https://www.bobcookdev.com/inkscape/inkscape-dxf.html

hmm at the above link it says Inkscape uses 1/90 of an inch and mentions other potential bugs, but this is from 2009...

According to documentation, the flattened SVG file option should create a viable SVG using the raw CAM setting, but all I get is overly complex and garbled output.

https://www.freecadweb.org/wiki/index.php?title=Draft_SVG#Preferences

https://forum.freecadweb.org/viewtopic.php?t=6396

It almost looks as if DXF-->SVG-->(1)SVG-->DXF will be necessary. This is way to complex and time consuming perhaps there is a way to create some python scripts or macros to fix this and batch process files. A more complex code project might be to adapt existing code libs to make svgnest into dxfnest.

I sent an email about all this. Also see User talk:AbeAnderson

I'm looking at modifying the isoview macro for SVG output. This seems excessive and adds more steps, but the FreeCAD SVG export is not creating useable files.

http://opensourceecology.org/w/images/b/b8/Iso_view.FCMacro

There are some existing tools to combine, merge, stack SVG's into one file.

https://stackoverflow.com/questions/14562136/merging-multiple-svg-files-into-one

This one works by merging and placing space between them.

https://github.com/astraw/svg_stack

I used the drawing WB to manually export SVG's of the track chain link ok, but it still requires editing out all the FreeCAD stuff then making 88 copies of the link in inkscape. I am assuming scaling of 1.0 will correlate the size correctly relative to 90ppi in Inkscape. Further reading of https://github.com/Jack000/SVGnest clarifies some functions. I'm thinking the easiest way to create a 4'x8' bin for the steel sheet is to draw and export it as an SVG as well. Then all the other SVG's at same scale can be copied in.

I'd like to think we can bypass that extraneous FreeCAD code and just write each part to a plain SVG, but the built-in class functions may make that more code work than ideal.

DXF files are dimensionless so as I recall you can set the scale in LibreCAD. So now I am thinking as long as the scales are the same for the orthographic projection in drawing bench (maybe 0.1) parts can be copied in to the 4'x8' bin file for upload.

Problems with scale, exporting everything at 0.1 did not help apparently. Also still have some inconsistencies or confusion in part diameters. I created a test file anyway. It doesn't seem to work I think because when I try to select the bin it only selects a side of the box. So something about the XML is off.

Fri Oct 6, 2017

Issues with existing components of the track are making it hard to edit so I am going back through the parts and constraining and editing them to more recent standards. For small simple parts like this, I think a fully editable assembly would be nice if I can figure out an ideal working chain.

added notch to track link. Also noticing the existing track unit example files are drawn with parts of various incorrect measurements like 3/4" thick rollers. Not sure what the actual specs are that have been used in the past other than logically basing it all around 1/2" plate. Probably better not to have so much slop in the rollers, but spacing the track links close to 1/2" may make them hard to weld to the track pad.

re-assembling track unit with fully editable parts constrained symmetrically for ease of future editing. spacing on the links is ~0.6"

next steps are the 3/4" bolts needed to replace old pin design and 1/2" thick rollers. Unsure if roller specs need to be adjusted +/- 0.05" for bolts. Sounds safe to assume torch kerf will be enough.

Tues Oct 4, 2017

Researching track design further and attempting to notch the tracks without redrawing entirely, but some glitches or misalignment in the original design seem to be making that difficult. I see the pin size is also likely incorrect since the roller ID is 0.75", which seems more reasonable if as large high-grade bolts are rather expensive. I see information that the bolt size for 1" is excessive. It would be ideal to reduce sizes as much as possible to reduce waste in nesting. For nesting, there may be scraps that could have smaller parts cut out first, but this would require hand optimization of the nesting since the software is unaware what is scrap.

Mon Oct 2, 2017

Created PTO motor mount plate sketch absed of PTO motor polanar to frame. sketch still needs work.

File:PTO Motor Mount plate.fcstd

1hr

Sat Sep30, 2017

looking at PTO motors again smallest one I see still looks a little big, but I assume will work fine if flow is lower.

http://www.surpluscenter.com/Brands/Dynamic/4-95-cu-in-PTO-Drive-Motor-9-7368-80.axd

I should be able to quickly modify the previous hydraulic motor from the PC1708 into a PTO.

Researched PTO Motor and redrew CAD using previous hydraulic motor from PC17.08 as starting point. Didn't seem to save much time maybe a little. Editing flow is often confusing and/or buggy. I found no CAD or detailed diagrams so measures are rough.

PTO Motor File:PTO Hydraulic Motor.fcstd

Also needs mount to back of tractor based on rough pattern. considering torque I'm guessing 2 large high grade bolts are sufficient for shear forces.

Fri Sep 29, 2017

edited and uploaded 3 bolt hole clamp to half then made compound.

clamp halves are difficult to make a complete compound from. Parts copied or merged disappear. The method that worked this time was making half compound then copying in the pocket (one part needs to be rotated 180deg) then make a final compound from the two. simpified compounds seem to have too little information to copy or merge without bugs.

added clamps to master CAD

also tried to add left motor mount and motor, but parts continue to disappear in FreeCAD.

Sep 28, 2017

changed clamp design and fit two on micro trac loader arm shaft.

Sep 25, 2017

uploaded file of larger track for wide microtrac version. Size may need further adjustment due to track path settings. the small microtrac tracks already appear too small relative to idlers. [File:MT track1.fcstd]

Going through small items on tractors.

Sep 23, 2017

updated PC 17.08 and MC CAD with holes and bolts. Surprisingly difficult to get everything well aligned and positionally correct.

added contact info to sheet.

2hrs

Sep 22, 2017

trying to check some the small things off the list on the MC CAD.

I ended up not making adjustments to shorten the motor mount plate because it appears to lower the sprocket to much, but I am not sure that is the right size either.

I've been attempting to add the holes to the PC to mount through tubing holes on the frame. Unfortunately, FreeCAD keeps behaving in strange and unexpected ways and finally crashed. I had to go back to the earlier version as I can not pocket holes through the compound for some reason. I nearly had the holes aligned before it crashed. I keep thinking I'll get used to it, but it is never as fast and simple as it should be.

Sep 19, 2017

meeting prep

checking last weeks meeting notes. adding editing Q&C to this weeks.

speed watched other half of freecad programming 101

Sep 17, 2017

edited and uploaded motor mount plate to extend height. It took longer than it should have because there was not an sketch editable version of the plate with the motor mount holes so I traced it and Fully constrained the sketch. I also see the motor mount holes can't be right so I am constraining it to the motor to find the correct hole pattern next.

added mounting plate to MC master CAD. Had bugs and issues again taking longer than it should. The plate looks closer but still needs adjustment. Maybe .25 to .5" shorter. Should also triple check hole distances and sizes for all bolts even though they look ok now. I attempted to replicate the right side to left, but keep encountering bugs. The motor compound needs rework first anyway.

3 hrs

Sep 16, 2017

adjusted tracks further and added 9 inch tracks compound to tractor master cad. Track still not perfect if accurate representation is desired, but close enough for now since other adjustments around the track still need to be made.

Also logging entries into wiki for easier accessibility until concerns with new web interface are resolved.

1hr

Old Logs

2017

- AbeAnd Logs August

- AbeAnd Logs July

- AbeAnd Logs June

- AbeAnd Logs May

- AbeAnd Logs April

- AbeAnd Logs March

- AbeAnd Logs February