Frame Construction Set: Difference between revisions

| Line 3: | Line 3: | ||

#CNC cut from flat - then welded or epoxied - works best with welding, second best with epoxy (more difficult) | #CNC cut from flat - then welded or epoxied - works best with welding, second best with epoxy (more difficult) | ||

#Welded from flat bar | #Welded from flat bar | ||

#PVC with [[Formufit]] | #PVC with [[Formufit Corners]] as in [[D3D Ohio]] | ||

#Aluminum extrusion | #Aluminum extrusion as in [[D3D_v18.06.12#CAD]] | ||

=Frame from Flats= | =Frame from Flats= | ||

Revision as of 11:44, 4 October 2018

Introduction

There are different options for the D3D frame that have been tested:

- CNC cut from flat - then welded or epoxied - works best with welding, second best with epoxy (more difficult)

- Welded from flat bar

- PVC with Formufit Corners as in D3D Ohio

- Aluminum extrusion as in D3D_v18.06.12#CAD

Frame from Flats

BOM

- 30' of 1/8"x1" flats, $13.50 from Sweiger Shop

- Self mixing epoxy, 3 tubes at $4 each, $13 total [1]

Procedure

- Using 1/8" by 1" flats, here is how you make a frame:

- Cut flats to 12"

- Clean and grind edges to be glued

- Assemble frame over a template

- Fix frame to another metal template with magnetic attachment

- Glue ends with self-mixing epoxy on both sides

Build

We used the old cnc'd square as a form. On top of the form, I placed a thin layer of plastic cut slightly larger than the square (the plastic prevents the epoxy from sticking our new square-from-flats to the old cnc'd square).

Using the square as a guide, I cut the first flat. Because the flat was slightly shorter than the square, I measured an additional distance of 1/2" past the length of the outer-edge-of-square to the inner-edge-of-sqaure. I marked this with soap stone & cut the first (of four) length of flat.

My first flat was going to be the guide for the other 3x flats in the square, so I got it exactly the right length, then I threw it in a vice, and grinded down the ends. I especially ground down the very end to be fine-ish point (like you would with a knife) so that the epoxy could penetrate more easily between the ends. I repeated this process for the 3x other flast, making sure that each was the same length as the first flat.

When all 4x flats were finished, I put them into the shape of a square ontop of the cnc'd square. The plastic obstructs the view of the cnd'd square underneath, but you can feel the edge & line it up fairly well.

Next, I took the other cnc'd square & put 16x magnents on it. I put 2x magnets on either side of the corners, about 3 finger-widths from the inside. Then I flipped this magnet-laden square over ontop of the other squares to make a square-plastic-flats-square sandwich.

I carefully re-aligned the flats into a square (again, using the bottom-most square as a guide) after the magnet shifted it a bit. After ensuring everything was aligned, I followed the directions on the 60-second epoxy & began adhering the flats into a square.

You really do have to work quick with this quick-set epoxy. I stopped for a second to think about how much epoxy I should be applying, and the epoxy hardened in the tip before my 4th join. So I used 2x tips on the first square.

Then I flipped it over carefully (the magnets on the top part of the sandwich did a great job at keeping everything together), and removed the square + plastic layers of the sandwich (which, after flipping, was now on top).

I changed tips & applied epoxy to the other side of the flats, this time without stopping.

I waited 5 minutes, but the form was clearly not set. Our "Devcon home" 1250 psi epoxy (bought at the local hardware store) says "30-60 second handling time", "2-5 minute set time", and "1 hour cure time". So we waited 1 hour.

After the hour, the form was still not strong. All the joints held, but it was very wobbly. And the epoxy was still soft.

Marcin & I were talking about passing on the epoxy solution, but perhaps continuing with the strips-to-build-a-square solution via welding. Or possibly spot welding so it could be done in a setting such as a library.

For more on this, see D3D_frame_built_with_epoxy

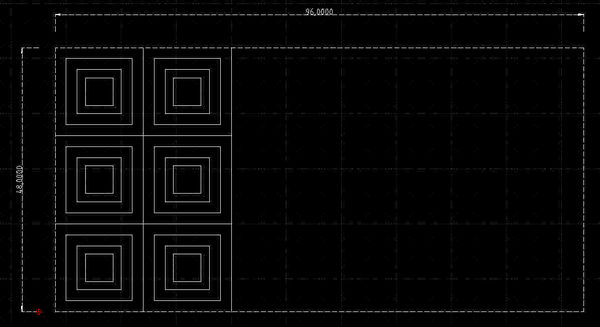

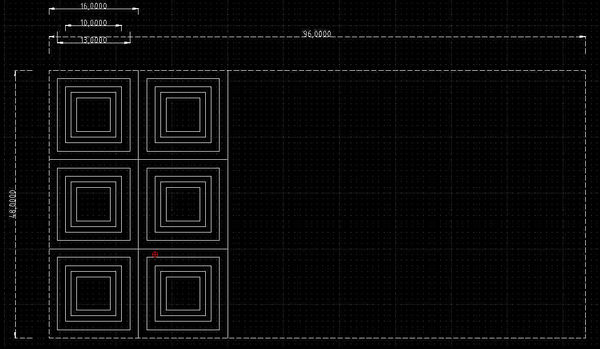

CNC Cut File for Starting from Sheet Steel

3-Nested

4-Nested

Cut Request Template

(can use oxyfuel, plasma, laser, or waterjet)

Hello,

Please provide a quote and turnaround time for CNC cutting for the attached file, cut from 4'x8' sheet, 11 gauge.

I need 6 of those nested sets (as shown in the file), which take a total of 32" of a 96" long sheet. I have more notes on this cut job at D3D Frame (below).

Thanks, Marcin

Download

- Download Layout on a 4'x8' sheet of steel: File:D3dframe layout.dxf

- Download Single nested frame piece: File:D3dframe.dxf

Notes:

- Frame pieces are square:

- 16" for outer square, 2" edge width

- 12" for outer square, 2" edge width

- 8" for outer square, 1.5" edge width

- Save the inner square. It will be used for mounting plates.

- if sheet is not exaclty 4'x8', an edge must be drawn around the frame so that every outer nested piece is exactly 16" on the side.

- 3 nested pieces can make 3 frames (each frame is made of 6 pieces

Online Viewer

View online by uploading the above file - http://dwgfastview.gstarcad.net/Flash/choose.html

Cost Estimates for Various Locations and Quantities

Single

- Chile-

- Maine -

- Texas Frame Cutting Quote - $157

- USA Missouri - Brian Neal - Seaman and Schuske, St. Joseph Missouri - job cost $150 for cutting of the nested set above.

Multiple

- 2017 - 6 sets of frames, 10 ga, no holes, 4 nesting, Seaman and Schuske, St. Joe, Missouri, USA - $575 - 2017

- 6 sets of frames, 10 ga, Seaman and Schuske, with holes, 5 nesting 16-14-12-10-8 - $860 with shipping - $36 down to 10"

Order Email

Hi Brian,

Thank you for the last order.

I have another order for 2 sheets of gauge 11 or 1/8" mild steel. It is another set of frames - nested on a 4x8 foot sheet. There is 5 nestings + inner cutout. Please see DXF.

It is similar to a previous order, but slightly different.

I need 2 full 4x8 sheets of this - meaning a total of 108 pieces per 4x8 sheet - for a total of 216 parts.

Do you see any issues with warping if it's 1/8" steel and the widths of sides are 1" ?

Please provide a quote and delivery time.

Thanks, Marcin

Marcin,

The two sheets of nested frames for the sum of $820.00 plus $40.00 delivery. About a week of lead time for 11GA. 3-4 working days for 10GA or 12GA mild steel.

My laser operator doesn't think warping will be a factor.

I will be on vacation after today for a week so ask for Randy if I'm not here.

Thanks

Brian Neal

Seaman and Schuske Metal Works

1215 S 4th Street

St. Joseph, MO 64501

Phone 816-232-3337

Mobile 816-752-0315

Email bneal@seamanschuske.com

Summary

If 18 frame sets are counted, that is $46/frame without shipping. If we count up to 30 sets, then it is $29 per frame with shipping.

Development Document

Development Discussion

Social Media

Links

- Critical Path for D3D 2016 - edit

See Also

- D3D_frame_built_with_epoxy. Note that 2 part epoxy (not JB Weld) did not work to make each of the 6 sides.