D3D v18.06.12: Difference between revisions

(→Log) |

No edit summary |

||

| Line 46: | Line 46: | ||

[https://docs.google.com/spreadsheets/d/1JIXpup3Tw7Bz0_1d46IBGCPihsLS-d-r0GF2zzD1B6I/edit edit] | [https://docs.google.com/spreadsheets/d/1JIXpup3Tw7Bz0_1d46IBGCPihsLS-d-r0GF2zzD1B6I/edit edit] | ||

= Physics = | |||

How fast is the 3D printer? Can we make it faster? What [[Stepper Motor| steppers]] should I buy? | |||

Traditionally, the knowledge about 3D printer parts, is passed in form of experiment results from older generations of developers. They give good reference points but are less flexible. For example when we build a printer small | |||

printer S which consumes 200W [https://reprage.com/post/39698552378/how-much-power-does-a-3d-printer-use] and | |||

a larger printer L consumes 400W. Does a printer with intermediate dimensions M consumes 300 W? | |||

Other interesting questions arrize: | |||

* When we want to print twice that fast, do we need stepper motors with twice the torque? | |||

* Can we save energy just by a smart controlling of the printer motion? There is a whole branch in applied mathematics [https://en.wikipedia.org/wiki/Optimal_control]. | |||

== Mechanics == | |||

== Stepper Motors == | |||

I would like to demension stepper motors out of the mechanical properties of 3D printer. | |||

* [[Stepper Motor]] | |||

* [[Stepper Motor Calculations]] there are only view information. | |||

* Dimensioning of step | |||

= Log = | = Log = | ||

*[[Ruslan Log]] | *[[Ruslan Log]] | ||

Revision as of 08:28, 4 November 2018

Development Template

For other 3D printers see 3D Printer Genealogy.

Conceptual Design

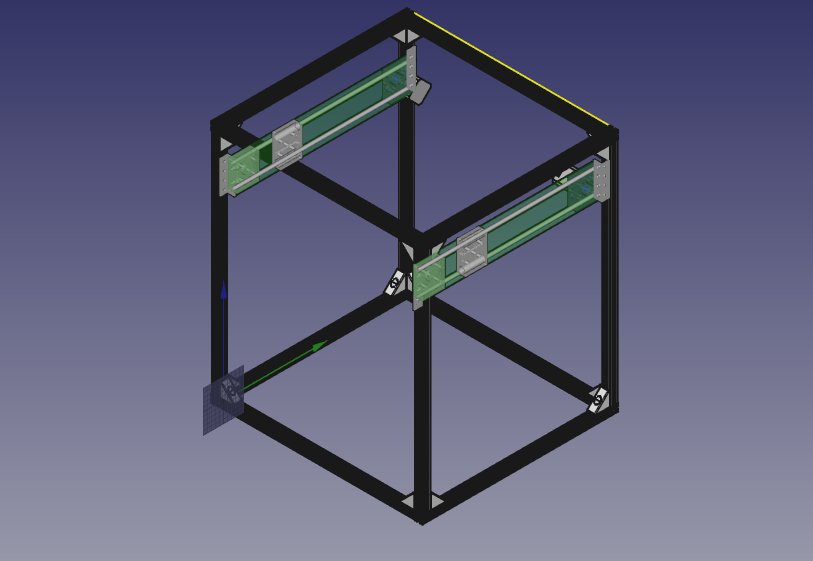

This is a German adaptation of OSE D3D printer. The major differences are:

- It uses T-slot profiles for the frame. It uses preferably parts from UniProKit developed by OSE-Germany.

- It uses metric system.

The remaining parts are similar:

- We use Universal_CNC_Axis.

Optional features:

- Be easier to transport.

- Possibility 1: Use handles as in SolarBox.

- Possibility 2: One should be able to disassemble the printer. The T-Slot profile makes it possible. User:Oliver criticizes this option. It is not useful because time consuming: Disassembling, Assembling, and Calibration.

CAD

For axis orientation I use as reference D3D Ohio v18.02 Universal axis are from [1]. The main difference to OSE-US:

- round edges to prevent warping when made from ABS plastic

- no magnet sockets

File:3d-printer-germany-v18.06.12.fcstd

BOM

Physics

How fast is the 3D printer? Can we make it faster? What steppers should I buy? Traditionally, the knowledge about 3D printer parts, is passed in form of experiment results from older generations of developers. They give good reference points but are less flexible. For example when we build a printer small printer S which consumes 200W [2] and a larger printer L consumes 400W. Does a printer with intermediate dimensions M consumes 300 W? Other interesting questions arrize:

* When we want to print twice that fast, do we need stepper motors with twice the torque? * Can we save energy just by a smart controlling of the printer motion? There is a whole branch in applied mathematics [3].

Mechanics

Stepper Motors

I would like to demension stepper motors out of the mechanical properties of 3D printer.

- Stepper Motor

- Stepper Motor Calculations there are only view information.

- Dimensioning of step