Charcoal Gasifier: Difference between revisions

Jump to navigation

Jump to search

m (Minor Clarification) |

m (Minor Text Formatting Fix) |

||

| Line 2: | Line 2: | ||

*There are some advantages with using charcoal (rather than wood) for gasification (section taken from: [[Troy Martz Gasifier]]). These may include: | *There are some advantages with using charcoal (rather than wood) for gasification (section taken from: [[Troy Martz Gasifier]]). These may include: | ||

**Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours. | **Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours. | ||

**The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for [[biochar]]... | **The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for [[biochar]]...what a great byproduct to have | ||

**We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and | **We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and dust…easily done. | ||

**Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass. | **Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass. | ||

**We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “Imbert” design | **We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “Imbert” design | ||

Revision as of 20:59, 12 October 2025

Basics

- There are some advantages with using charcoal (rather than wood) for gasification (section taken from: Troy Martz Gasifier). These may include:

- Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours.

- The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for biochar...what a great byproduct to have

- We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and dust…easily done.

- Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass.

- We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “Imbert” design

- We can scale gas production with the same system by merely swapping out a single nozzle size – we can go from 2kW to 50kW with the same machine!

- Yes, charcoal has less BTU’s, but we can also utilize those BTU’s by capturing and using that heat with a smart charcoal retort design

- Charcoal gasifiers have the potential to produce far more powerful gas flow than biomass gasifiers... Cracking steam is the key.

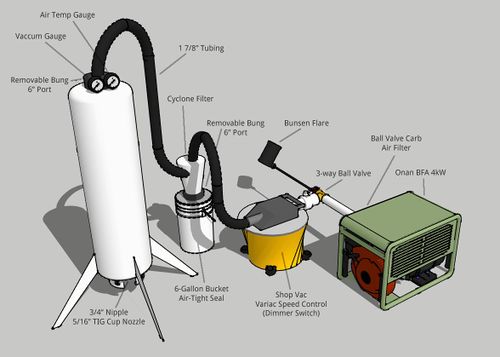

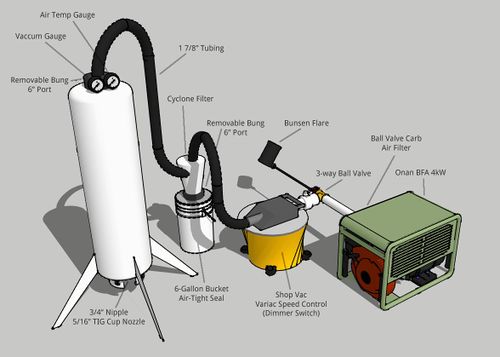

Troy Martz Gasifier - gasifies charcoal

Videos

Internal Links

- Gasifier 3D CAD (For OSE’s Latest Design)

- Compressed Fuel Gas

- Troy Martz Gasifier - gasifies charcoal

- Biomass to Fuel

- The Biochar Economy and Kon-Tiki Kiln