Steam Engine Design/Valves: Difference between revisions

mNo edit summary |

No edit summary |

||

| Line 2: | Line 2: | ||

Various types and kinds of valves used in steam engines are summarized here. | Various types and kinds of valves used in steam engines are summarized here. | ||

# Steam Engine Design/Valves | |||

* Steam Engine Design/Bump Valve | |||

* Steam Engine Design/Piston Valve | |||

* Steam Engine Design/Slide Valve | |||

* Steam Engine Design/Solenoid | |||

* Steam Engine Design/Rotating Valve | |||

* Steam Engine Design/Pressure Relief Valve | |||

* Electric Valves for Steam Engine | |||

=General Valve Notes= | =General Valve Notes= | ||

| Line 13: | Line 23: | ||

'''Uniflow Engines''' | '''Uniflow Engines''' | ||

"Steam Engine Valves", Pg. 107 describes Uniflow Engines. Steam admission is done with drop valves. | "Steam Engine Valves", Pg. 107 describes Uniflow Engines. Steam admission is done with drop valves. | ||

=Control Valve Designs= | |||

[[Image:Improved-Bump-Valve.png|thumb|Improved Bump Valve]] | [[Image:Improved-Bump-Valve.png|thumb|Improved Bump Valve]] | ||

=Bump (or Bash) Valve= | ==Bump (or Bash) Valve== | ||

See [[Steam Engine Design/Bump Valve]] | See [[Steam Engine Design/Bump Valve]] | ||

| Line 22: | Line 34: | ||

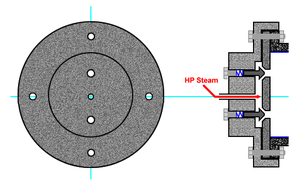

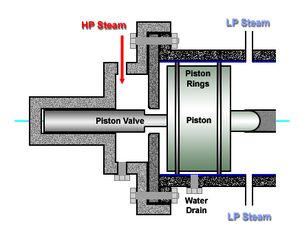

[[Image:Piston-Valve.png|thumb|Piston Valve]] | [[Image:Piston-Valve.png|thumb|Piston Valve]] | ||

=Piston Valve= | ==Piston Valve== | ||

See [[Steam Engine Design/Piston Valve]] | See [[Steam Engine Design/Piston Valve]] | ||

| Line 29: | Line 41: | ||

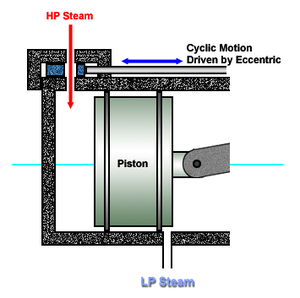

[[Image:Slide-Valve.png|thumb|Slide Valve]] | [[Image:Slide-Valve.png|thumb|Slide Valve]] | ||

=Slide Valve= | ==Slide Valve== | ||

See [[Steam Engine Design/Slide Valve]] | See [[Steam Engine Design/Slide Valve]] | ||

| Line 35: | Line 47: | ||

A popular valve used in many early and model steam engines. | A popular valve used in many early and model steam engines. | ||

= | ==Solenoid Valve== | ||

See [[Steam Engine Design/Solenoid]] | |||

=Rotating Valve= | Computer controlled solenoid valves allow complete control over steam admission into a cylinder. An earlier version of the [[Steam Engine Design/2009]] was focused on using solenoids as the control mechanism. While OSE may return to that as a control technique, an open source solenoid needs to be designed and developed capable of handling steam pressures (200+ psi). | ||

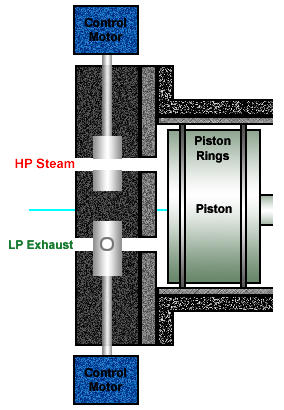

[[Image:Rotating-Valve.png|thumb|Rotating Valve Design]] | |||

==Rotating Valve== | |||

See [[Steam Engine Design/Rotating Valve]]. | See [[Steam Engine Design/Rotating Valve]]. | ||

A rotating ball or cylinder controlled by a stepper motor that allows precise, computer control over when steam is admitted into the piston chamber. | A rotating ball or cylinder controlled by a stepper motor that allows precise, computer control over when steam is admitted into the piston chamber. | ||

=Pressure Relief Valves= | |||

==Weight Based Pressure Relief== | |||

See [[Steam Engine Design/Pressure Relief Valve]]. | |||

=Flow Control Valves= | |||

* Needle valves | |||

[[Category:Steam Engine]] | |||

Revision as of 16:59, 22 June 2011

Main > Energy > Steam Engine

Various types and kinds of valves used in steam engines are summarized here.

- Steam Engine Design/Valves

* Steam Engine Design/Bump Valve * Steam Engine Design/Piston Valve * Steam Engine Design/Slide Valve * Steam Engine Design/Solenoid * Steam Engine Design/Rotating Valve * Steam Engine Design/Pressure Relief Valve * Electric Valves for Steam Engine

General Valve Notes

Placement of Exhaust Port Placement of the exhaust port in the cylinder wall vs. the fully extended position of the piston matters as it determine the amount of time that steam has to escape the chamber. If the distance is too short, steam will be compressed on the return stroke.

Water Build-up If water builds up in the cylinder without some way to relieve it, it can result in a blow-out of the cylinder end caps. Perhaps the water drain plug can be a valve itself, held in place with a strong string. If water builds up in the cylinder, it will eventually force the water drain valve to open and blow out some of the water. Springs will have to hold against the maximum steam pressure, however.

Uniflow Engines "Steam Engine Valves", Pg. 107 describes Uniflow Engines. Steam admission is done with drop valves.

Control Valve Designs

Bump (or Bash) Valve

See Steam Engine Design/Bump Valve

The bump valve is our primary candidate for the first prototype of the OS Steam Engine. Simplicity is in it's favor, but has also been shown to work successfully in other steam engines, particularly the White Cliffs steam engine (see Steam Engine Design/White Cliffs.

Piston Valve

See Steam Engine Design/Piston Valve

The piston valve eliminates the need for a spring to hold the valve against the valve seat when steam is not being let into the cylinder chamber.

Slide Valve

See Steam Engine Design/Slide Valve

A popular valve used in many early and model steam engines.

Solenoid Valve

See Steam Engine Design/Solenoid

Computer controlled solenoid valves allow complete control over steam admission into a cylinder. An earlier version of the Steam Engine Design/2009 was focused on using solenoids as the control mechanism. While OSE may return to that as a control technique, an open source solenoid needs to be designed and developed capable of handling steam pressures (200+ psi).

Rotating Valve

See Steam Engine Design/Rotating Valve.

A rotating ball or cylinder controlled by a stepper motor that allows precise, computer control over when steam is admitted into the piston chamber.

Pressure Relief Valves

Weight Based Pressure Relief

See Steam Engine Design/Pressure Relief Valve.

Flow Control Valves

- Needle valves