Replication: Difference between revisions

(→Dorkmo: Tulsa, Oklahoma, USA: adding Dandelion Village) |

William Neal (talk | contribs) No edit summary |

||

| Line 138: | Line 138: | ||

We plan to build a two story house this year (2012) with the bricks from the CEB Press. More buildings are planned for next year, some of which may include bricks from the CEB Press, depending on how production goes on the first home. | We plan to build a two story house this year (2012) with the bricks from the CEB Press. More buildings are planned for next year, some of which may include bricks from the CEB Press, depending on how production goes on the first home. | ||

== Tony Mensah, Mark Amo-Boateng, William Neal: Nanjing, China == | |||

In May, 2012, this group, originally from Ghana and Canada, set out to redesign the CEB press to metric specifications and build it with the help of some engineers at a factory in Ma'anshan, Anhui, China. According to a report received on September 27th, there are some technical issues surrounding the later stages of assembly of the CEB press, particularly centred around the secondary cylinder and the soil shaker. Mark has scheduled more time at the factory to work out these details. More information will be posted as it becomes available. | |||

= Archive = | = Archive = | ||

Revision as of 12:41, 27 September 2012

| Replication Discussions Feel free to discuss your ideas and experiences regarding replication on the GVCS Replication category of our forum. |

Overview

Using the Civilization Starter Kit, people are beginning to independently build their own Global Village Construction Set machinery throughout the world. Many of them have come to Factor e Farm for Dedicated Project Visits, and others have taught themselves based on our training materials. We conduct program evaluations to learn from and document their experiences, and we predict 100 independent replications by the end of 2013.

Replicators Network Surveys

The Replicators Network Surveys are designed to help us learn from independent replicators and move forward in our pursuit of identifying economic best practices. To use a metaphor, each set of documentation and the design idea they represent are like a hypothesis, and independent replications are ways of testing the soundness of our estimates. The surveys, then, help us gather information about the results of the experimentation that takes place across our global network of independent replicators. By participating in this process, you help the Open Source Ecology community learn and fulfill its mission.

Open Source Ecology - Replicators Network Surveys - February 2012

Complete Responses

Replication Activity

- Stage 1 - Planning

- Stage 2 - Fabrication

- Stage 3 - Complete

Daniel & Hayden: Pasadena, California, USA

D&H Tractors

We are D & H, Daniel and Hayden, 12th grade students at the Polytechnic School in Pasadena, CA.

We, along with our engineering class and several students from nearby Blair High School, intend to build a Lifetrac from the plans of Open Source Ecology. We will donate the tractor to The South Central Farmers Cooperative, for use on their 120 acre farm in Shafter, CA.

Our rationale for taking on this project is three pronged. By being among the first- and the first high school aged students- to replicate the Lifetrac, we are doing a service to the Open Ecology Project, and, consequently, may be helping change the future of agriculture everywhere. Our project will, likewise, benefit the South Central Farmers, who are eager to experiment with open source agricultural technology. Finally, bringing a project like this to the Polytechnic School (and, in a smaller degree to Blair High School) will provide aspiring engineers with a chance to use their skills in the field before leaving for college.

Manuel Aguilar: Guatemala

Quetsol

Manuel is a TED Global Fellow and is a co-founder of Quetsol. Quetsol offers appropriate technology solutions that sustainably provide for the energy demands of a wide variety of users at a lower social and economic cost.

Our project, currently in late planning stages, is building a sustainable village for about 30 families recently displaced by extreme weather in Guatemala. The village model will approach sustainability in an integral way, from housing design and construction to agriculture and resource management. Residences, for example, will incorporate appropriate materials (CEB mostly), passive solar design, and come standard with rain-catchment systems with prefiltration, mini greenhouses, efficient wood/methane stoves, water filtration, PV for light/comm, compost toilets, water recycling. Agri and aquaculture will be efficiently designed as well as per local conditions (location TBD soon). The aim will be to demonstrate a working prototype of a self-sustainable community built for the BOP, which can, when designed and built appropriately, economically replace the current minimum denominator settlements which cause so much human and environmental hazard. Ultimately we intend to build something replicable and scalable, which is where OSE comes in.

OSE will integrate into our work in a variety of ways. Initially, we aim to train a skilled replicator so that some of the first GVCS machines can be built on site and facilitate village construction and development. We also plan to build and equip a workshop in which to build the initial machines and which will also eventually serve as a high-value business opportunity to some trained villager entrepreneurs. Beyond the machines built for village use, which will generate value at reduced cost - income will be generated initially from fabricating machines for local distribution. Eventually, they workshop will also expand to include training of locals, so that other such businesses may sprout in other communities. This is in keeping with the OSE ethos, and at the core of many of our intentions with our project. The village aims to demonstrate that post-scarcity abundance can be achieved, even with the lowest means found amongst the BoP, with appropriate use of technology. OSE provides a fantastic set of tools and methodologies that potentiate development precisely through intelligent open-source design and tech.

In terms of time frame, in the next month, we will have purchased land, identified a replicator, finished first project proposal and begin land work. April I will be travelling abroad for 3 weeks, so construction of the first living Unit will take place mid-May. During summer, June-Aug, we will build the workshop and at some point fabricate the CEB press after having the replicator receive proper training. After this is accomplised, we will build the residential units and have the families begin to move in, as they will also be helping build their own houses.

Andrew Spina: Baltimore, Maryland, USA

Machining Independence

I'm building my own tractor because I want to understand it and be able to maintain it. It's also a project that will teach me many valuable skills. I've already learned a ton about machining and CAD.

Finally, I'm interested in joining the material economy at some time in my life. So far I've earned my living by working in the knowledge economy. I think really hard and get paid to do it. I'm employed as a programmer. It's a job I love, but constrains my life quite a lot-- I work 40hr a week and have to commute to my place of work. One day, I'd like to have a bit more control-- perhaps program as a hobby.

What do I mean by 'material economy' (a green wing article)? I mean that I take ingredients and make a product. The product is a tangible thing that solves a tangible problem like hunger, need for shelter, etc. This is important because the tangible problems are the ones that force the average person to take a 9 to 5. If I can provide fixes for these root human needs, I'll have high security (someone somewhere is hungry) and be encouraging smaller scale self sufficiency. The OSE folk argue (see Village Scale here) that a material economy of about 200 people is enough for comfortable modern living locally. That sounds like somewhere I'd want to live.

So what will I produce in the material economy? I mean really, what will my tractor produce? I don't have a firm plan, but my current thoughts are to produce pelletized biomass. With a few tools (Tractor, Hay Cutter, Hammer Mill, Pelletizer) and some land, I may be able to produce a renewable, carbon neutral (or even negative!) local fuel. I'm not yet clear on the economics-- how much land make how many pellets? How much labor for each acre of land? How much do pellets cost? Where would I sell them? But, I'm going to have a tractor regardless so if the economics don't work, I'll find a different plan.

James Slade: Austin, Texas, USA

Creation Flame

"October, 2011 marks the first ever replication of a complete GVCS machine by an independent third party. This is a day of historical significance for the Global Village Construction Set. Congratulations to James Slade of Texas."

- Marcin Jakubowski, Nov. 14, 2011

James Slade is one of the co-founder's of Creation Flame in Cedar Creek, Texas. In partnership with Jason Smith, Creation Flame is the first to successfully replicate a CEB press and is now getting into the business of using and selling CEB blocks. In unison with Thad from Broken Sidewalk Farm, they are starting production of a LifeTrac, self replicating CNC Plasma table, and another Powercube. Also starting to build a few Roller Tables to help with the CEB's and steel work.

See corresponding Blog Post. See Patrick Gibbs Interview of James Slade regarding this replication.

CEB brick pressing results from Creation Flame: CEB Blocks

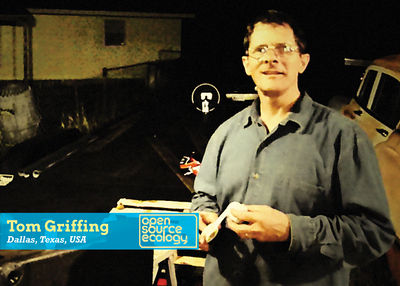

Tom Griffing: Dallas, Texas, USA

Pondus, LLC

Tom Griffing operates Pondus LLC in Dallas, Texas.

After spending nearly a month in Missouri in August, Tom has continued his efforts in documentation, design enhancements and in replicating his first Power Cube. He is now targeting a LifeTrac after making improvements on our Power Cube Prototype 4 design.

Video: Power Cube Prototype 5 - Tom's updated design of the Power Cube.

Photo: Enhanced Power Cube - the first Power Cube sold by Tom.

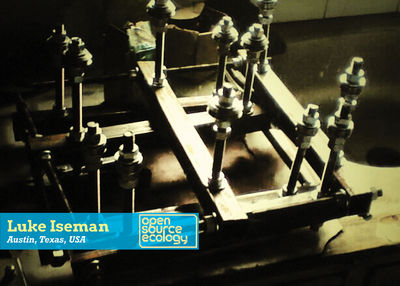

Luke Iseman: Austin, Texas, USA

re:char

Luke worked on making improvements to the CNC Torch Table and made a dedicated project visit to Factor e Farm in December, 2011.

Luke is chief technology officer for re:char. He graduated, cum laude, from The Wharton School at the University of Pennsylvania, concentrating in Entrepreneurship and Operations. Luke is passionate about open source hardware, and his projects have been covered by Make Magazine, Boingboing, Wired, and The Austin Chronicle. Before joining the re:char team, Luke worked at a variety of software technology companies, built and managed a fleet of 25 pedicabs, invented an automated gardening computer, and wrote a book about traveling around the world. Luke is excited about using the power of the physical computing revolution to build a more sustainable world.

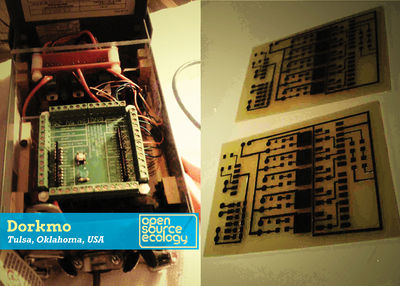

Dorkmo: Tulsa, Oklahoma, USA

Dorkmo

Dorkmo is a user from Oklahoma with a background in tinkering, and he enjoys spreadsheets.

He has independently replicated the Detroit Board and the CEB Controller Box.

Dandelion Village: Bloomington, Indiana, USA

Zach Dwiel is a cofounder of Dandelion Village, an ecovillage in the city limits of Bloomington, Indiana. We are in the process of assembling a CEB Press. James Slade fabricated the steel parts, and Dandelion Village designed and built the controller board and electronics, purchased the hydraulics and assembled the machine.

We plan to build a two story house this year (2012) with the bricks from the CEB Press. More buildings are planned for next year, some of which may include bricks from the CEB Press, depending on how production goes on the first home.

Tony Mensah, Mark Amo-Boateng, William Neal: Nanjing, China

In May, 2012, this group, originally from Ghana and Canada, set out to redesign the CEB press to metric specifications and build it with the help of some engineers at a factory in Ma'anshan, Anhui, China. According to a report received on September 27th, there are some technical issues surrounding the later stages of assembly of the CEB press, particularly centred around the secondary cylinder and the soil shaker. Mark has scheduled more time at the factory to work out these details. More information will be posted as it becomes available.

Archive

For old ideas on Replication, check the Archive.