Replication

| Replication Discussions Feel free to discuss your ideas and experiences regarding replication on the GVCS Replication category of our forum. |

Overview

Using the Civilization Starter Kit, people are beginning to independently build their own Global Village Construction Set machinery throughout the world. Many of them have come to Factor e Farm for Dedicated Project Visits, and others have taught themselves based on our training materials. We conduct program evaluations.

Replicator's Survey

If you have built any of the GVCS machines, we'd like to hear about your experience for learning purposes. Please email us at info at opensourceecology to share your experience, or add your build to this page.

Daniel & Hayden: Pasadena, California, USA

D&H Tractors

We are D & H, Daniel and Hayden, 12th grade students at the Polytechnic School in Pasadena, CA.

We, along with our engineering class and several students from nearby Blair High School, intend to build a Lifetrac from the plans of Open Source Ecology. We will donate the tractor to The South Central Farmers Cooperative, for use on their 120 acre farm in Shafter, CA.

Our rationale for taking on this project is three pronged. By being among the first- and the first high school aged students- to replicate the Lifetrac, we are doing a service to the Open Ecology Project, and, consequently, may be helping change the future of agriculture everywhere. Our project will, likewise, benefit the South Central Farmers, who are eager to experiment with open source agricultural technology. Finally, bringing a project like this to the Polytechnic School (and, in a smaller degree to Blair High School) will provide aspiring engineers with a chance to use their skills in the field before leaving for college.

- Slides: http://imgur.com/a/eZq7t/embed

- High School Presentation: http://vimeo.com/36147461

Manuel Aguilar: Guatemala

Quetsol

Manuel was co-founder of Quetsol. Quetsol offers appropriate technology solutions that sustainably provide for the energy demands of a wide variety of users at a lower social and economic cost.

Our project, currently in late planning stages, is building a sustainable village for about 30 families recently displaced by extreme weather in Guatemala. The village model will approach sustainability in an integral way, from housing design and construction to agriculture and resource management. Residences, for example, will incorporate appropriate materials (CEB mostly), passive solar design, and come standard with rain-catchment systems with prefiltration, mini greenhouses, efficient wood/methane stoves, water filtration, PV for light/comm, compost toilets, water recycling. Agri and aquaculture will be efficiently designed as well as per local conditions (location TBD soon). The aim will be to demonstrate a working prototype of a self-sustainable community built for the BOP, which can, when designed and built appropriately, economically replace the current minimum denominator settlements which cause so much human and environmental hazard. Ultimately we intend to build something replicable and scalable, which is where OSE comes in.

OSE will integrate into our work in a variety of ways. Initially, we aim to train a skilled replicator so that some of the first GVCS machines can be built on site and facilitate village construction and development. We also plan to build and equip a workshop in which to build the initial machines and which will also eventually serve as a high-value business opportunity to some trained villager entrepreneurs. Beyond the machines built for village use, which will generate value at reduced cost - income will be generated initially from fabricating machines for local distribution. Eventually, they workshop will also expand to include training of locals, so that other such businesses may sprout in other communities. This is in keeping with the OSE ethos, and at the core of many of our intentions with our project. The village aims to demonstrate that post-scarcity abundance can be achieved, even with the lowest means found amongst the BoP, with appropriate use of technology. OSE provides a fantastic set of tools and methodologies that potentiate development precisely through intelligent open-source design and tech.

In terms of time frame, in the next month, we will have purchased land, identified a replicator, finished first project proposal and begin land work. April I will be travelling abroad for 3 weeks, so construction of the first living Unit will take place mid-May. During summer, June-Aug, we will build the workshop and at some point fabricate the CEB press after having the replicator receive proper training. After this is accomplised, we will build the residential units and have the families begin to move in, as they will also be helping build their own houses.

See Guatemala Log for more details.

Andrew Spina: Baltimore, Maryland, USA

Machining Independence

I'm building my own tractor because I want to understand it and be able to maintain it. It's also a project that will teach me many valuable skills. I've already learned a ton about machining and CAD.

Finally, I'm interested in joining the material economy at some time in my life. So far I've earned my living by working in the knowledge economy. I think really hard and get paid to do it. I'm employed as a programmer. It's a job I love, but constrains my life quite a lot-- I work 40hr a week and have to commute to my place of work. One day, I'd like to have a bit more control-- perhaps program as a hobby.

What do I mean by 'material economy' (a green wing article)? I mean that I take ingredients and make a product. The product is a tangible thing that solves a tangible problem like hunger, need for shelter, etc. This is important because the tangible problems are the ones that force the average person to take a 9 to 5. If I can provide fixes for these root human needs, I'll have high security (someone somewhere is hungry) and be encouraging smaller scale self sufficiency. The OSE folk argue (see Village Scale here) that a material economy of about 200 people is enough for comfortable modern living locally. That sounds like somewhere I'd want to live.

So what will I produce in the material economy? I mean really, what will my tractor produce? I don't have a firm plan, but my current thoughts are to produce pelletized biomass. With a few tools (Tractor, Hay Cutter, Hammer Mill, Pelletizer) and some land, I may be able to produce a renewable, carbon neutral (or even negative!) local fuel. I'm not yet clear on the economics-- how much land make how many pellets? How much labor for each acre of land? How much do pellets cost? Where would I sell them? But, I'm going to have a tractor regardless so if the economics don't work, I'll find a different plan.

James Slade: Austin, Texas, USA

Creation Flame

"October, 2011 marks the first ever replication of a complete GVCS machine by an independent third party. This is a day of historical significance for the Global Village Construction Set. Congratulations to James Slade of Texas."

- Marcin Jakubowski, Nov. 14, 2011

James Slade is one of the co-founder's of Creation Flame in Cedar Creek, Texas. In partnership with Jason Smith, Creation Flame is the first to successfully replicate a CEB press and is now getting into the business of using and selling CEB blocks. In unison with Thad from Broken Sidewalk Farm, they are starting production of a LifeTrac, self replicating CNC Plasma table, and another Powercube. Also starting to build a few Roller Tables to help with the CEB's and steel work.

See corresponding Blog Post. See Patrick Gibbs Interview of James Slade regarding this replication.

CEB brick pressing results from Creation Flame: CEB Blocks

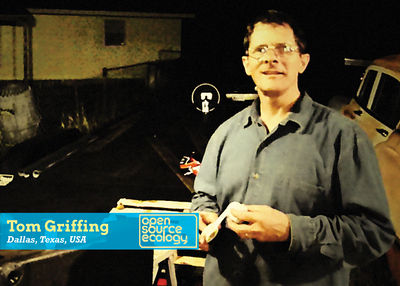

Tom Griffing: Dallas, Texas, USA

Pondus, LLC

Tom Griffing operates Pondus LLC in Dallas, Texas.

After spending nearly a month in Missouri in August, Tom has continued his efforts in documentation, design enhancements and in replicating his first Power Cube. He is now targeting a LifeTrac after making improvements on our Power Cube Prototype 4 design.

Video: Power Cube Prototype 5 - Tom's updated design of the Power Cube.

Photo: Enhanced Power Cube - the first Power Cube sold by Tom.

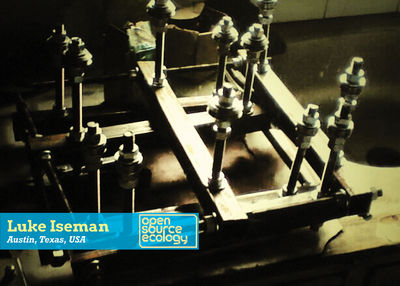

Luke Iseman: Austin, Texas, USA

re:char

Luke worked on making improvements to the CNC Torch Table and made a dedicated project visit to Factor e Farm in December, 2011.

Luke is chief technology officer for re:char. He graduated, cum laude, from The Wharton School at the University of Pennsylvania, concentrating in Entrepreneurship and Operations. Luke is passionate about open source hardware, and his projects have been covered by Make Magazine, Boingboing, Wired, and The Austin Chronicle. Before joining the re:char team, Luke worked at a variety of software technology companies, built and managed a fleet of 25 pedicabs, invented an automated gardening computer, and wrote a book about traveling around the world. Luke is excited about using the power of the physical computing revolution to build a more sustainable world.

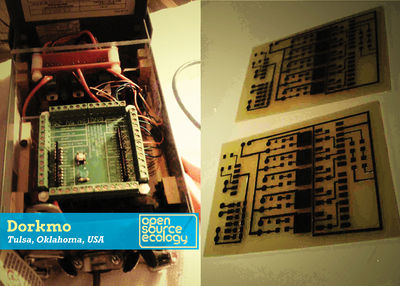

Dorkmo: Tulsa, Oklahoma, USA

Dorkmo

Dorkmo is a user from Oklahoma with a background in tinkering, and he enjoys spreadsheets.

He has independently replicated the Detroit Board and the CEB Controller Box.

Dandelion Village: Bloomington, Indiana, USA

Zach Dwiel is a member of Dandelion Village, an ecovillage in the city limits of Bloomington, Indiana. They are in the process of building their first home using a CEB Press and Power Cube. Tom built our Power Cube. For the CEB Press, James Slade fabricated the steel parts, Zach designed and built the controller board and electronics, purchased the hydraulics and Dandelion Village assembled the machine.

Zach plans to build a two story house this year (2012) with the bricks from the CEB Press. More buildings are planned for next year, some of which may include bricks from the CEB Press, depending on how production goes on the first home. You can find updates on my blog: blog and my house design here on this wiki: Dwiel House

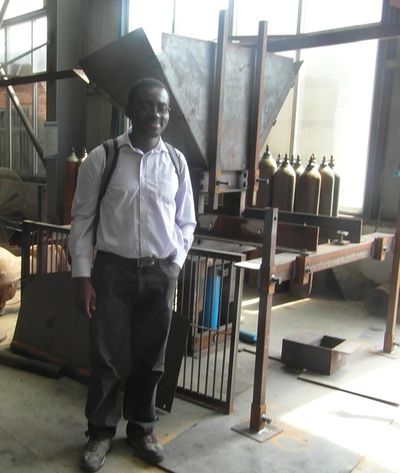

Tony Mensah, Mark Amo-Boateng, William Neal: Nanjing, China

China Replication

In May, 2012, this group, originally from Ghana and Canada, set out in Nanjing to redesign the CEB press to metric specifications and build it with the help of some engineers at a factory in Ma'anshan, Anhui, China.

According to a report received on September 27th, there were some technical issues surrounding the later stages of assembly of the CEB press, particularly centred around the secondary cylinder and the soil shaker.

In June, 2013, the group was finally able to test the brick press - successfully (youtube link).

Charles Liptaak

Charles Liptaak's Replication

File:Charlescebrep3.jpg File:Charlescebrep4.jpg File:Charlescebrep5.jpg File:Charlescebrep6.jpg File:Charlescebrep7.jpgFile:Charlescebrep8.jpg File:Charlescebrep9.jpg

User Review

We made a bunch of bricks and found some areas to improve:

- Every once in a while the drawer jumped off the rollers and jammed. This is probably due to the hydraulic cylinder not being perfectly in-line with the drawer and pushing it slightly sideways. To fix this we removed the rollers and added 8 bearings, 4 to hold it up and 4 to prevent it moving it sideways. Now it works much better. This will also simplify the construction of the drawer, which now can be made with flat bottom rails.

Once I fix the second and third problems below, I’ll send you images/video

- Could be missing something here, but I’m finding the magnet/sensor combination unreliable. – I had the machine working perfectly, but after just having it sit there for two months, the sensors failed to pick up the magnets. Maybe I need to build the hall effect sensors little differently and perhaps out of a different material, but even moving the magnets manually in front of the sensors produced intermittent results.

Have you experienced anything similar? Have you considered other types of sensors/ control mechanisms?

- Fried my Aurdrino board. Totally self-inflicted. Had some issues with the software recognizing the cylinder positions at startup, and to override things I wanted to have manual controls. The manual override worked and the cylinders moved into position ok, but the feedback loop killed the board. Have you figured out how to add manual override switches?

- Wrt your other email on the power cube, we added an adjustable pressure bypass valve to the pump. This way if a cylinder is bottomed/topped out, the engine can keep running without stressing the pump. The only issue is cosmetic – we didn’t have enough room to do this within the frame and the hose is on the outside of the cube. – photos to follow

Response by MJ

- Agreed, the roller guide mechanism is the weak point. We have not had the drawer slip off the rollers when they were adjusted properly with the roller raisers. After a few thousand bricks - the machine loosened up such that the rollers were no longer holding the drawer tight. The drawer slipped off the rails, so we tightened the roller raisers and the drawer did not slip. However - we see this as an issue to be addressed - and we did that in CEB Press Prototype IV with the new modular roller mechanism designed by Marshall Hilton. Since the roller guides were a weak point - we made the rollers modular and more robust for easy installation.

- We found the magnet/sernor set finicky as well. We have a new design in CEB Press Prototype IV. See CEB_Press#Electronics_-_CEB_Press_IV.

Response by Zach Dwiel

- I've got a CEB Press with the newest roller mechanism (I believe), and haven't had any trouble yet, but also haven't pressed too many bricks yet.

- I also just ordered parts to add a pressure relief valve, which should probably be standard.

- I would love to know what the new design is that is replacing the old magnet/sensor set (I couldn't find any information on that link you provided other than the new control board I designed.) I'm part way through a rewrite of the code, but would rather wait and work on a newer version if there are new ideas. I was planning on writing an initialization step that required some manual control to 'show' it where the boundaries are, but that will be for nothing if the actual sensors are flakey

Italy

Up to 2012

Here is a clickable document (click edit below the drawing to access links) - all machines built up to 2012:

Itemized

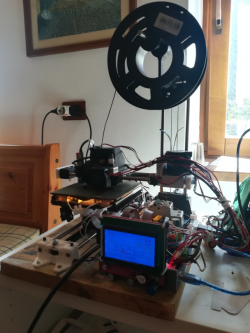

2022

D3D Universal v21.06 replica in Cadore, Italy - up and running

2019

- D3D @ Fontys Sittard

- Ciruit plotter by Ferdi Log - see https://feadi.github.io/OSE/

- Universal Axis 3D printer - 3 in China, Canada, and Guyana by William Neal

2018

- Universal Axis 3D printer - SZOIL in Shenzhen, China.

- CEB Replication in France

- CEB Press in South Africa - Tsolo Moahloli <tsolo@bothopele.com>

2017

- See D3D Genealogy - there is a number of 3D printer replications in different countries.

2016

- Brick press in france-

2015

2014

- CEB Press - for Scott Mader

- CEB Press - for Midwest Renewable Energy Fair

- CEB Press - for Factor e Farm

- PowerCube - Structural 1&2

- MicroPowerCube 2&3

- Lulzbot TAZ- 12 3D printers built in a workshop

- MicroCar - Velocar partial prototype

- MicroHouse 2

- MicroHouse 3

- MicroHouse 4

- Danny Epperson - PowerCube v6 in Austin, TX - [3]

- CEB Build in Chile

- CEB Build in India

- CEB Build in Texas 2014

- CEB Build - Rob Beddingfield - USA

- MarsTrac

- Nicaragua Replication - 2 brick presses and power cubes?

Note: counted 110 total machines as of end of 2014. 12 are 3D printers. 2 are the CEB presses and 4 power cubes in Nicaragua, thought the Nicaragua replication awaits confirmation. 27 not done by OSE headquarters, of these, 12 are brick presses. 8 countries of replication: USA, Chile, Nicaragua, Guatemala, China, India, Italy, Turkey.

2013

OSE builds:

- Laser Cutter - [4]

- LifeTrac 5

- LifeTrac 6

- Backhoe Prototype 3

- Ironworker Prototype 3

- MicroHouse 1

- MicroPowerCube 1

- Lulzbot TAZ build - with CNC Mill Spindle - Aidan Williamson

Counted 73 machines as of end of 2013.

Replication FAQ

- Q: Ironworker - Is any documentation for prototype 3 available or is it just not ready to be released for replication at this point? I found a sketchup file but it doesn't appear to have enough information and most of the modules on the dozuki site do not have any content.

- A: The ironworker has been built and tested, but not documented well. We took it to desructive testing, so it's not a machine that we are currently using. See https://www.youtube.com/user/marcinose/search?view_as=subscriber&query=ironworker. However we are still using the earlier prototype, see Ironworker Genealogy.

- Q: CNC Torch Table -There is a youtube video from the microfactory startup camp in which Marcin explained the history of the work on this and the ambitions for version 19.10 and was curious whether you had a rough timeframe in mind when you thought a prototype and documentation might be available whether it be a year, three years, five years, or so.

- A: CNC_Torch_Table_v19.10 has some documentation, and we'll be publishing test and usage data as a result of the Summer X 2020

- Q: CNC Torch Table - From skimming though the documentation available thus far it looks like the table may be able to be reasonably replicated but it didn't look like it would be sufficient to piece together the electronics without a strong background in this. If the prototype for version 19.10 goes well following the Summer X 2020 workshops, do you anticipate full documentation being available shortly afterwards?

- A: Definitely

- Q: Power Cube - Which version would you recommend to run the CEB press? It looks like the power cube prototypes are generally 28 horsepower so I assumed that this was sufficient to run the CEB press cylinders at a decent pace and it appeared that version 7 had pretty clear documentation.

- A: Power Cube VII works, but it's more difficult to build, so we recommend the newest one, Power Cube v17.10 for ease of build. We are still continuing development, and shifting to the Changfa Diesel in the next iteration for longevity.

- Q: Power Cube - Do you have an idea for when documentation for the Changfa Diesel version would be available? It looks like version 17.10 has 64 hp and 16 hp models and I was wondering if the 16 hp model would be sufficient to operate the new soil mixer/CEB press machine or is that a question that you wouldn't be able to answer until it is prototyped?

- A: 16 will work fine, you can do 17.10 and it will work. We will document the Changfa diesel in this summer as well.

- Q: CEB Press: Is the intention for the soil mixer to create a stockpile of stabilized material that would then be loaded into the CEB press with a loader or for the material to run from the chute of the soil mixer directly into the press? If the material is intended to run directly into the CEB press would the current version with their large hoppers be able to run in tandem since the chute appears to be lower than the hoppers of the CEB presses?

- A: The large hopper will be put on the soil mixer, and a small hopper would be on the actual brick press - see

and Soil Mixer 2019 for more details.

and Soil Mixer 2019 for more details.

- A: The large hopper will be put on the soil mixer, and a small hopper would be on the actual brick press - see

Archive

- Old survey - Old 2012 Survey - [5]

- For old ideas on Replication, check the Archive.