Sawmill

- HABITAT: CEB Press - Sawmill - Living Machines - Modular Housing Units

- AGROECOLOGY: LifeTrac Multi Purpose Tractor - MicroTrac - Power Cube - Agricultural Spader - Agricultural Microcombine - Hammer Mill - Well Drilling Rig - Organoponic Raised Bed Gardening - Orchard and Nursery - Modular Greenhouse Units - Bakery - Dairy - Energy Food Bars - Freeze Dried Fruit Powders

- ENERGY: Pyrolysis Oil - Babington Burner - Solar Combined Heat Power System - Steam Engine Construction Set - Solar Turbine - Electric Motors/Generators - Inverters & Grid Intertie - Batteries

- FLEXIBLE INDUSTRY: Lathe - Torch Table - Multimachine & Flex Fab - Plastic Extrusion & Molding - Metal Casting and Extrusion

- TRANSPORT: Open Source Car

- MATERIALS: Bioplastics

Introduction

Sawmill - highly versatile and valuable lumber if woodlot is available - or lumber may be bought from neighbors. Decentralized sawmilling may obviate clear-cut lumber companies in a new economy. Many uses. Flex fab opportunity. Lends itself highly to the type of modular structures proposed by the Center for Maximum Potential Building Systems - look for GreenForms at http://cmpbs.org/flash/download.htm . Lends itself highly for flex fab production, especially kits. Fabrication is absolutely simple - after metal is cut - only a drill press is required. Zero welds in structure, with minor welding for motor attachments. DfD, lifetime design. Driven by a hydraulic motor powered from tractor hydraulics.

As a first attempt at a robust and replicable sawmill, we are proposing a chainsaw mill, like a Logosol, with a 25 hp hydraulic motor.

Update Dec. 2, 2008: Based on a comment from our blog, we decided to pursue a circular blade mill, one like the Mobile Dimensions Saw.

The current prototype is a dimensional sawmill. In a dimensional sawmill the log is stationary while the blades and motors move. They have 3 circular saw blades: one main vertical blade, and 2 smaller horizontal blades. They cut a whole piece of lumber, like a 2 inch by 4 inch board, in each pass.

Collaboration

Review of Project Status

Nov. 2008: Robert Todd is entering as project manager. Dec. 2008: Jeremy Mason is entering the project onsite, until Robert returns to Factor e Farm. At that point, Jeremy and Robert will work together.

Local Sawmills

- http://simpsons-nativehardwoods.com/page7.html - St. Joseph, MO

- Watkins Sawmill - Stewartsville, MO - (816) 669-3218

Sawmill - Current Work

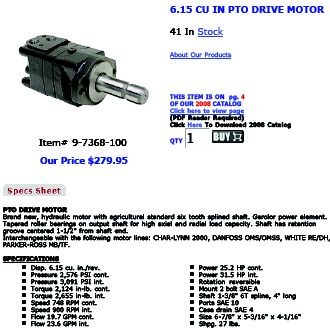

We have a hydraulically-driven PTO motor as a start. It will be powered by LifeTrac. All hoses are already available - it is part of our flexible open source tractor infrastructure. Here are the motor specifications, from Surpluscenter.com:

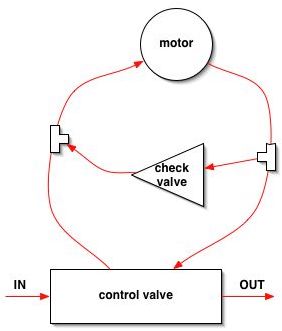

Here is the hookup diagram:

Note: Since we have 3600 PSI available, we can run 2 of these motors in series to match available power more closely.

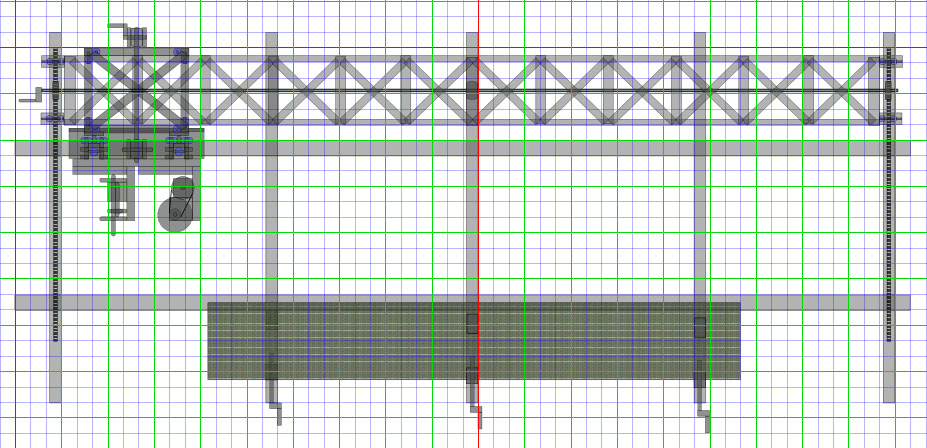

A very preliminary prototype drawing, top view:

Sawmill - Developments Needed

Sawmill - General

Sawmill Design Rationale

Must adhere to OSE specifications. (Open documentation. Low cost and easy to manufacture/replicate. Design for life, disassembly, repair. Robust, multipurpose.)

Must be able to cut about 2400-3000 linear feet of dimensional lumber per day.

Must handle up to 3000 lb logs.

Must cut 4x4s and flat 2x of large width.

Motor Rationale Must use hydraulic power from LifeTrac.

Power is about 40 hp - available from 55 hp Deutz, at .72 system efficiency.

Hydraulic motors utilize 24 gpm at up to 3600 PSI. Each motor is 40 hp, around 700 RPM.

2 Cushion valves are used for stopping in bidirectional configuration.

2 spool control valve needs to handle the full fluid flow (24 gpm) to each motor.

To use power effectively, one should be able to control the amount of flow to each of the two motors, from full power in one to full power in the other.

Main blade RPM - 2000 RPM. Edger blades - 5000 RPM.

Simple pulley system, with single pulley of 3x for main blade. Double pulley for edger blades, about 2.5 ratio for each.

Platform Function Rationale

Needs a platform that will be able to hold the weight of the motors, pulley system, blades, and frame. The weight of the platform will be about 25 lb. per motor, etc for a total of about 200 lbs. The platform must be stable enough to make straight cuts. The platform should be able to roll in the x axis. The platform must move precisely and hold securely in the y and z axes. The y and z axis movements must be about 3-4 feet for large logs.

Function List

2 edger blades on same axle

2 edger blades are adjustable

Move onto hydraulic log handling later

Move on to automatic sawmill operation with remote control, for ease of cutting.

Allow for log turning in addition to taking slices out of the wood

Safety cage around blades

Blade cooling soapy water?

Logs loaded with tractor loader

Mechanism to secure log to track

use bearings to ride on a flat track?

Design developments

Oct 2008: We are still narrowing down an option for the sawmill. We are considering a chainsaw mill, and here are some comments on multipurpose sawmills

Jan 2009 developments:

Jan. 2, 09: We decided that the MDS design looks pretty straightforward and that it should be used as the base for the OS sawmill. http://www.mobilemfg.com/

Looked into space frames like the MDS frame. http://en.wikipedia.org/wiki/Space_frame

Read about trusses. http://en.wikipedia.org/wiki/Truss

Need to learn the calculations for materials.

Need to contact Ben and ask questions about the MDS and sawmill.

Where can blades be bought from?

Jan. 4, 09: We have narrowed down the design to something similar to the MDS space frame (for stability) on two 'I' beams for x and y axis movements, a chassis surrounding the space frame with bearings to grip it on all sides, a vertical plate or beams on the chassis with another plate attached with bearings and adjusted vertically with a pulley for the z axis, the MDS like saws are mounted on the vertically moving plate and powered with hydraulic motors and pulleys to get the correct RPMs.

Could the saw assembly use a swing blade system for reduced cost? It would have to be stable though.

http://www.truthaboutax.com/site/1515517/page/875294

http://www.petersonsawmills.com/products_asm.htm

http://www.skillmill.com/index.htm

Jan 13: Made 2d design and worked on bill of materials.

Sawmill Research

Dimension sawmills appear to have the highest output:

http://forestry.about.com/cs/portamills/a/portamill_inter_3.htm

For production, a chainsaw mill can mill 200 to 400 board feet per day, a band mill can mill 800 to 2,000 board feet per day, swing mills can produce 1,500 to 3,000 board feet per day and dimension mills 2,000 to 4,000 board feet per day. A lot depends on log size, species and products being cut.

Circular saw blades appear to be easy to manufacture, repair, and have a good lifetime.

http://www.woodweb.com/knowledge_base/Sawmill_recovery_rate.html

Price comparison of sawmills

http://www.woodsmansawmillcompany.com/

| Woodsman | $12,000 | |

| Lucas | $13,000 | |

| Peterson | $20,000 | |

| Mobile Dimension | $25,000 | |

| Mighty Mite | $30,000 |

30" blades seem too expensive for most operations, a 20" blade might work and be much more affordable currently.

Cheapest 30" $1200:

http://www.amazon.com/Lackmond-CW1301751-Walk-Behind-Concrete-Blades/dp/B00112W9L4/ref=sr_1_10?ie=UTF8&s=hi&qid=1231132591&sr=1-10

Cheapest 20" $150: http://www.amazon.com/Amana-720360-Heavy-Duty-Ripping-Blades/dp/B000P4HN2Y/ref=sr_1_29?ie=UTF8&s=hi&qid=1231132318&sr=1-29

Bill of Materials

system at 3600 psi, 24 gpm

Base frame

Approx. 3.5-4in wide/high x 19ft long "I" beams x2

Track frame

Approx. 3.5-4in wide/high x 8ft long "I" beams x5

Gear rack, about 6ft long x 1-2in wide

Log clamps

threaded shaft

handle

metal pieces ("L" shape?)

shaft bearing?

Jacks

threaded shaft

handle

shaft bearing?

base pad

Space frame

2in "L" angle approx. 17-18ft x4

2in x 18in steel x? 2in x ? steel braces x?

Large Gears x2

Small Gears x2

Gear Pipe

Gear pipe bearings x3

Gear pipe handle

metal for holding small gears

metal for holding bearings

Saw Platform

Frame

2in x 1/8in x 20in steel x12

metal to hold bearings

Vertical asssembly

6ft? "I" beams x2

2 stopper L pieces for top and bottom about 2ft wide

pulley cable

pulley mount and wheel on top

pulley handle with locking teeth (spring tensioned?)

Saw Motor Frame

2 hydraulic motors - 40 hp each, 3600 psi

2 cushion valves, 24 gpm, 3600 psi

2 spool, 25 gpm valve

Hydraulic Hoses

Motor couplers

Motor coupler, main

Motor coupler, secondary

1 pulley,2.5x

2 pulley system, 2.5x each

1 main belt

2 secondary pulley belts

Main saw blade - 20"

2 edger blades - 9"

2 shafts for blades

3 attachments systems for blade - Multimachine style

2 sets of 2 pillow blocks to hold blade shafts

Ball bearings and bearing shafts x48

16 for space frame track

16 for saw assembly frame

16 for vertical saw assembly

Bolts and nuts

Need cost sourcing for all pieces.

Implementation

With design rationale, put it up for review on Red Pages

Build space frame

Purchase one blade, 30", 2 blades, 12"

Build cutting head - gear up the blade

Install all safety devices before operating

Test sawmill operation without blades attached

Start with unidirectional cutting head, move on to bidirectional by upgrade

Sawmill - Specific

Sawmill - Background Debriefing

Sawmill - Information Work

Sawmill - Hardware Work

Sawmill - Sign-in

Development Work Template

- Sawmill - Product Definition

- Sawmill - Design Evolution

- Sawmill - Technical Design

- Sawmill - Deployment and Results

- Sawmill - Documentation and Education

- Sawmill - Resource Development

- Sawmill - Identifying Stakeholders

- Sawmill - Grantwriting

- Sawmill - Collaborative Stakeholder Funding

- Sawmill - Tool and Material Donations

- Sawmill - Charitable Contributions