Charcoal Gasifier

Jump to navigation

Jump to search

Basics

- There are some advantages with using charcoal (rather than wood) for gasification (section taken from: Troy Martz Gasifier). These may include:

- Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours.

- The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for biochar...what a great byproduct to have

- We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and dust…easily done.

- Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass.

- We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “Imbert” design

- We can scale gas production with the same system by merely swapping out a single nozzle size – we can go from 2kW to 50kW with the same machine!

- Yes, charcoal has less BTU’s, but we can also utilize those BTU’s by capturing and using that heat with a smart charcoal retort design

- Charcoal gasifiers have the potential to produce far more powerful gas flow than biomass gasifiers... Cracking steam is the key.

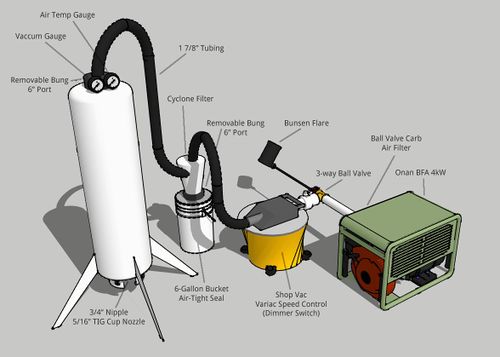

Troy Martz Gasifier - gasifies charcoal

Videos

Existing DIY/OS Designs

Greenhill Forge (YouTube Channel) 's Design

- A Video by the YouTube Channel "Greenhill Forge" Titled "Building a Simple Gasifier: FREE Engine Fuel from Charcoal" ( ~25 Minute Watch )

- Need to check with them if it's okay, but they have some GREAT infographics ~3:54

- Also 0:55 Safety Note was Apt

- "If you decide to experiment with gasification, please remember that it is LITERALLY a Carbon Monoxide making machine, and it can be extremely dangerous, so make sure you know what you are doing and do it safely

- Uncertain on if SynGas has any Methane in it, but minor mistake / that may be an unintentional product infrequently mentioned in giant plant designs etc

- I know Wood Gas / Pyrolysis Gas does tend to contain all sorts of gas species

Design Overview

- It is a Crossdraft Gasifier

- Made largely of welded together steel

- Uninsulated (Unlike the current OSE Design which uses a Fire Brick Hearth)

- It was made using a CNC Plasma Cutter , thus Files exist somewhere

- Intermittent Fillet Welds were used

- A Truncated U Shape is made over the Ash Grate to confine the reaction to a narrower space (presumably to follow the zone interacting with the air, almost the inverse of the "Dead Man" in Blast Furnaces )

- Oversized Inlet and Outlet Pipes (No exact dimensions mentioned)

- Only a linear (foreward and backward) Ash Shaker , will be interesting to see if that will clog up or not

- Largely depends on the Ash Content of the Charcoal , and the Hardness of the Shaker Grate? (ie can it grind up + "eat" the Bottom Ash / Clinker )

- In terms of Design for Cleaning , making that part easily accessible may be worthwhile)

- Largely depends on the Ash Content of the Charcoal , and the Hardness of the Shaker Grate? (ie can it grind up + "eat" the Bottom Ash / Clinker )

- Hinged Lid Reinforced with Square Tubing, and has a Gasket + Spring Latch

- Adhesive Fire Rope mentioned as a Gasket Material

- 3 Thermocouples "Stabbed In" (After being predrilled) and sealed with RTV Silicone

- A more robust solution may be warranted for LONG TERM use (ie if/WHEN a probe fails, and needs replaced etc), but for an experimental setup this is fine

- It then goes to a Cyclonic Filter

- Neat Gas Flare made using a standard Soup Can and Steel Tubing

- As per that Landfill Gas paper, probably the Chandelier Type? (Double Check This)

- Need to check an older video (with their albeit far more novel Charcoal Retort]] , but it seems this design DOES use Screened Charcoal

- Seems to be a Trommel of Welded Wire Mesh, akin to that used for fencing

- Exhaust Blower On + a Blowtorch put in the inlet for start

- 10-30 Second Startup until Self Sustaining Flare Flame

- Fuel Tank Removed from Engine, Engine Adapted to Drill Engine Starter , Fuel Line Capped Off, Carburetor / Throttle Body/ Fuel Assembly left in place as an easier experimental setup for that, dedicated replacement can be done later down the line

- A standard T-Fitting and Butterfly Valve (Neat DIY/OS Design using PVC Pipe made) is made for regulating Air-Fuel Mixture

- Flashback Arrestors / Explosion Proofing, or at least Leak Monitoring may be warranted on this side, has my safety spidey senses tingling a bit

Internal Links

- Gasifier 3D CAD (For OSE’s Latest Design)

- Compressed Fuel Gas

- Troy Martz Gasifier - gasifies charcoal

- Biomass to Fuel

- The Biochar Economy and Kon-Tiki Kiln