Open Source Lathe

- HABITAT: CEB Press - Sawmill - Living Machines - Modular Housing Units

- AGROECOLOGY: LifeTrac Multi Purpose Tractor - MicroTrac - Power Cube - Agricultural Spader - Agricultural Microcombine - Hammer Mill - Well Drilling Rig - Organoponic Raised Bed Gardening - Orchard and Nursery - Modular Greenhouse Units - Bakery - Dairy - Energy Food Bars - Freeze Dried Fruit Powders

- ENERGY: Pyrolysis Oil - Babington Burner - Solar Combined Heat Power System - Steam Engine Construction Set - Solar Turbine - Electric Motors/Generators - Inverters & Grid Intertie - Batteries

- FLEXIBLE INDUSTRY: Lathe - Torch Table - Multimachine & Flex Fab - Plastic Extrusion & Molding - Metal Casting and Extrusion

- TRANSPORT: Open Source Car

- MATERIALS: Bioplastics

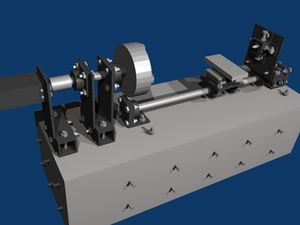

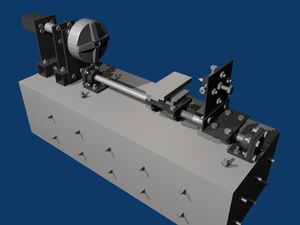

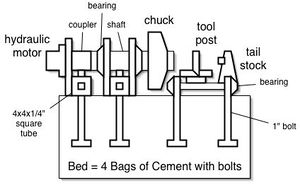

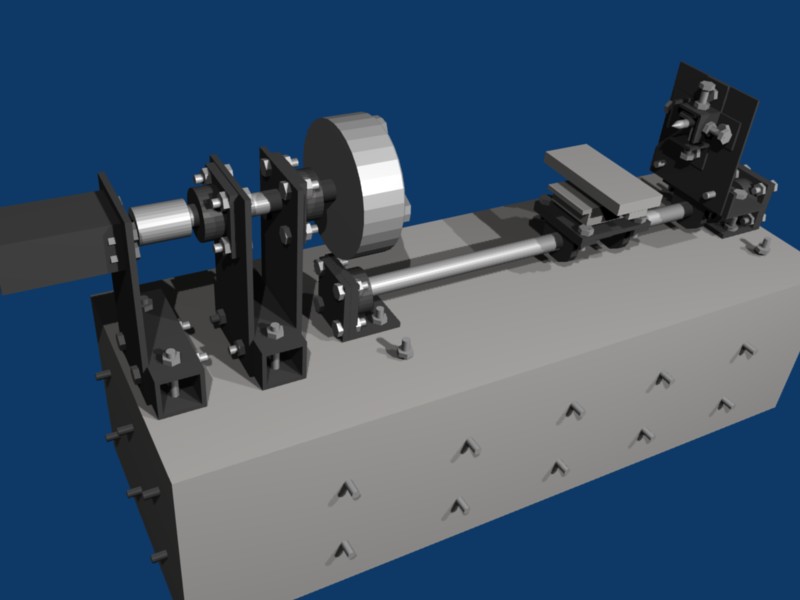

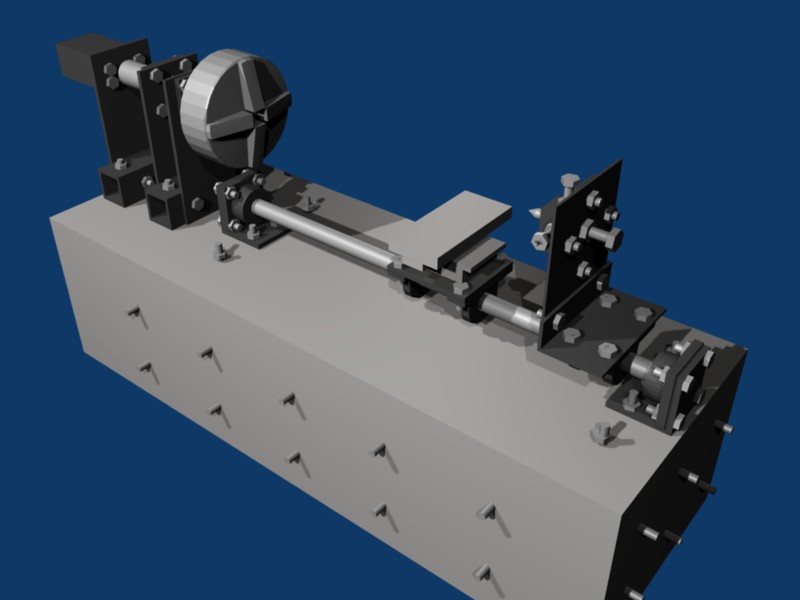

Here we are showing the details for fabricating a high-performance (2/1000" accuracy), high power (20 hp) lathe. It will be powered from the hydraulic take-off from a tractor - LifeTrac. The design follows that of the Multimachine. Instead of an engine block as the basic structural unit, we'll be using a concrete bed with metal mounting plates. The advantage of this route is that we are avoiding the necessity of sourcing and boring out the engine block. Moreover, the concrete bed will be its own lathe mount structure.

This route allows for the construction of a lathe from stock parts - metal plate, shaft, coupler, bearings, bolts, and concrete. We add a cross slide and chuck on top of that, and use a hollow shaft tube for workpiece feed-through:

Design Rationale

- High power, simple design

- OSE Specifications are met via low cost for replication; a transparent, open source development process; open documentation; product evolution infrastructure

- External power source

- Interchangeable motor - part of LifeTrac infrastructure, motor can be coupled to many different devices

- Hydraulic motor provides high power and torque with full speed control via a flow control valve

- Basic design:

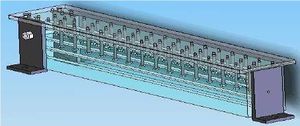

- Romig type lathe bed made of concrete(see below)

- Metal plates are used to attach functional parts of lathe to concrete bed

- Large hollow shaft attached to bearing blocks on plates

- Two bearings with bearing clamps holding bearings in place:

- Clamps as such hold the chuck in place

- Cross slide is mounted on another plate

- Tail stock?

Specifications

Fabrication and Cost

- Ease and low cost of fabrication is the primary goal, as a high-performance lathe is perhaps the most important tool in a workshop

- Construction consists of a concrete bed

- Cost is that of 4 bags of concrete for the bed, chuck, cross slide, and

- Motor cost is included in LifeTrac infrastructure

- Motor coupler to lathe shaft is machined

- Commercial chck is the main cost

- XY table constitutes a cross slide

- Tool post is fabricated

- 2" shaft constitutes a mounting surface for an xy table and for tail stock

- Feed-through shaft is present, but is only 1 foot deep

- Cheap 2 15/16" bearing

Specifications

- 12" lathe

- 1/1000" accuracy via bearing tolerance and chuck tolerance

- Heavy duty axial thrust acceptable, as determined by 3" shaft and bearings

- Radial thrust determined by set screws on 2 bearings, with 2 extra full split collars

Motor

Brute 20 horse of turning power is provided by a hydraulic motor powered by LifeTrac

Shaft Coupler from motor to shaft

Bearings

Chuck

We will fabricate a chuck from a 1" steel pate, as in:

- http://www.wttool.com/product-exec/product_id/13768?utm_medium=cpc&utm_source=froog

- http://www.grizzly.com/catalog/2009/Main/590

- http://www.google.com/products?q=lathe+chuck+4+jaw+12&hl=en&scoring=p

Slide

For the lathe to be able to handle large work pieces, the slide itself - which holds the tool post.

- Milling Drilling Slide $90

- http://www.google.com/products?q=%22cross+slide%22+-jewelry+-shoes&hl=en&scoring=p&sa=N&lnk=next&start=100

- http://www.shop.com/Cross_Slide_Vises-34856820-45455382-p!.shtml?sourceid=298

- http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=32997&zmam=33951326&zmas=12&zmac=112&zmap=32997

Tool Post

The tool post will have to mount securely to the cross slide.

Bill of Materials

- Romig bed lathe type - about 9 bags concrete mix

- 4x4x1/2" square tube 12" long, x 3

- 6x6x1/2" L angle 6" long, x 2

- 3x3x1/2" L angle 3" long, x 4

- 8x18x1/2" plate, x 3

- 12x10x1/2" plate - tail stock holder

- 8x9x1/2" plate - tool post slide holder

- 1-7/8" shaft 17" long

- 1-7/8" shaft 50" long

- 1-7/8" 4 bolt bearings with lock collar, x 4

- 1-7/8" Pillow block bearings with lock collar, x 2

- Milling Drilling Slide

- 4 jaw Chuck

- plate for mounting chuck

- attachments for chuck plate

- PTO Motor

- Motor to 1-7/8" shaft coupler

- 12" long bolts, with nuts and lock washers, x 12

- 16 4 bolt bearing bolts, with nuts and lock washers

- 4 pillow block bearing bolts, with nuts and lock washers

- 4 motor bolts, with nuts and lock washers

- 4 drilling milling slide bolts, with nuts and lock washers

- 6 plate bolts, with nuts and lock washers

- 4 tail stock L angle holding bolts, with nuts and lock washers

- 4 tail stock adjuster bolts, with nuts and lock washers

- 1 large tail stock bolt, with 2 large washers, lock washers, and nuts

- tool post

- 77" long rebar, x 3

- 29" long rebar, x 5

- Foundation frame materials:

- 74x23" board, x 2

- 26x23" board, x 2

- 27x75" board

- 28x3" board, x 4

Sourcing and prices

Steel @ $0.75 per pound.

| Part(s) | Total Weight | Price |

|---|---|---|

| 4x4x1/2" square tube 12" long, x 3 | 64.89 | $48.67 |

| 6x6x1/2" L angle 6" long, x 2 | 19.6 lbs | $14.70 |

| 3x3x1/2" L angle 3" long, x 4 | 9.4 lbs | $7.05 |

| 8x18x1/2" plate, x 3 | 61.2 lbs | $45.90 |

| 8x12x1/2" plate | 13.6 lbs | $10.20 |

| 8x9x1/4" plate | 5.1 lbs | $3.825 |

| 1-7/8" shaft 17" long | 13.36 lbs | $10.02 |

| 1-7/8" shaft 50" long | 39.29 lbs | $29.47 |

| Total | 226.44 lbs | $169.83 |

| Part(s) | Price |

|---|---|

| 1-7/8" 4 bolt bearings with lock collar, x 4 | $67.80 |

| 1-7/8" Pillow block bearings with lock collar, x 2 | $33.90 |

| Milling Drilling Slide | $89.95 |

| 4 jaw Chuck | $119.95 + $44 shipping = $163.95 |

| PTO motor | $279.95 |

| Tool post | $125 |

| Total | $760.55 |

Bill of Materials - Lathe

- Romig bed lathe type - from Multimachine -

- Simple prototype, $486 in materials BOM:

- 2 bearings, $50

- 2 mouning plates, 1/2"x6" angle - $40

- 4 Shaft Collars - $20

- 2" shaft - $20

- DOM tubing, 3", 2" ID - $15

- 8 3/4" bolts for table - $16

- Chuck plate - $40

- Bolts for chuck - $20

- Nuts and bolts for DOM - $5

- XY table - $70 off shelf at Enco - [1]

- Tool post - $10

- table plate - $30

- 2 bags of cement, 80 lb each - $20

- sand, gravel - $10

- TOTAL - $316

- High performance, 2/1000" accuracy with proper technique, stock parts, 1000 lb radial and 200 lb axial load capacity

Lathe Tools

Pictures

Links

- Light duty toy lathe - http://www.instructables.com/id/100-Homemade-Lathe/?ALLSTEPS