John Stager Log

![]() Hint: Log for John Stager, who worked on the HydraFabber in 2013.

Hint: Log for John Stager, who worked on the HydraFabber in 2013.

|

|

|

|

|

|

Permanent Links

Please coordinate between John Log, Leo Log, Tim Log, and Nate Log - all work related to HydraFabber.

Mon Oct 27, 2025:

LifeTrac 6 – Ghana Pilot & OSE Collaboration Proposal

Prepared by LifeTracGroup Inc (US HoldCo) & LifeTrac Tech Ltd (Ghana OpCo)

Executive Summary

We are launching a Ghana pilot of LifeTrac 6 with localized PowerCube and fabrication at a partner workshop in Ghana. Our goal is to execute a transparent, open, upstream-first build program aligned with OSE’s standards—then scale to a first production tranche. We request OSE’s review, a 60-minute call, and a 1-day on-site working session to align on latest LT6/PowerCube state, Ghana localization, and contribution pathways back to OSE.

Objectives

Validate LT6/PowerCube for Ghana materials, fittings, and supply chains.

Stand up repeatable fab/test procedures and QA in a local workshop.

Contribute improvements (drawings, BOM variants, jigs, test data) upstream to OSE.

Align on licensing/attribution and an ongoing collaboration cadence.

Scope (Pilot → Ramp)

Pilot (Dec 2025): Demo & field validation builds in Ghana (Ho/GRATIS workshop).

Ramp (2026): Month-by-month increase based on lessons learned and supply reliability.

Focus modules: LT6 chassis/frame, hydraulics, wheel assemblies, operator deck, PowerCube, loader (optional in pilot).

What We’re Asking From OSE

Current canonical LT6 + PowerCube docs: latest drawings/CAD, BOMs, fabrication notes, test/checkout steps, jigs/fixtures guidance.

Technical review of our Ghana BOM substitutions (steel profiles, hoses/fittings, hydraulics vendors, fasteners).

Guidance on preferred license/attribution language for wiki, drawings, and downstream publications.

Agreement on a data-sharing loop (test logs, failures, change notes) and where to post on the wiki.

Host a 1-day on-site working session at OSE to finalize localization and contribution plan.

What We’ll Contribute to OSE

Localized BOMs with supplier references and price/lead-time notes.

Field data: maintenance logs, failure modes, fixes, and parts wear studies.

Documentation upgrades: cleaned drawings where needed, assembly guides, and photo walkthroughs.

Attribution & openness: we’ll follow OSE’s standard attribution and upstreaming practices and seek your preferred wording.

Team

John Duse Stager – Founder, President & Chief Architect (US)

Mark Kofi Mallet – CEO

Evan Gordon – Chief Engineer (Additional Ghana workshop partners to be listed here as MoUs finalize.)

Timeline (Proposed)

Now → November 2025: OSE review, call, on-site visit; finalize Ghana BOM/jigs and QA plan.

December 2025: Pilot fab + demo/fielding in Ghana.

January–March 2026: Post-pilot improvements; readiness gates for first production tranche.

2026: Controlled ramp with continuous upstream contributions to OSE.

One-Day On-Site Working Session (Draft Agenda)

Context & goals (10m) LT6/PowerCube deep-dive: drawings, BOM, tolerances, QA (60m) Fab walkthrough & jigs/fixtures (45m) Ghana localization: materials, hydraulics, sourcing (45m) Open-source & attribution alignment (20m) Roadmap: first 10 tractors, parts/service loop, reporting (30m) Next steps & owners (10m)

Risks & Mitigations

Supply variability: dual-source lists; interchangeable fittings where feasible.

QA drift in new shops: gated checklists, sign-offs, and photo evidence in build logs.

Field conditions: early run-in + duty-cycle logs; rapid feedback/patch notes on wiki.

Metrics (Pilot)

Build hours by station; first-pass yield; rework hours.

Hydro leak rate, run-in temps/pressures; torque audit pass rates.

Field uptime; top 5 issues and fix lead time.

Documentation completeness (wiki checklist).

Thu Sep 5, 2013

Aug 30, 2013:

Task 27, Final CNC Mill Spindle Holder

Log:

The first try failed. The was some issue with the support material, piece orientation and the bed. The orientation of the piece has been change after consultation. Reprinting on Dimension Elite 3D printer started this afternoon. We will get the results, on Sept 3rd.

Aug 29, 2013:

Task 26, Final CNC Mill Spindle Holder

Log:

The printing of the cnc mill spindle holder started this afternoon on dimension elite 3d printer. The printed result will be ready tomorrow when the fablab reopens at 9.00 am.

Aug 26, 2013:

Task 24, Final CNC Mill Spindle Holder

Log:

Prepare spindle holder files for printing on Dimension Elite 3D printer.

Aug 22, 2013:

Task 23, Final CNC Mill Spindle Holder

Log:

My DPV is over, however I brought the Taz with me. I will finish from Fablab, Century College, White Bear Lake, MN.

Tasks left:

- Bed

- Working spindle assembly

- Fab modules workflow

Aug 20, 2013:

Task 22, Final CNC Mill Spindle Holder

Log:

Updated cnc spindle cad file We a still waiting on End Mills from Cobalt depot, They have not arrived.

Aug 18, 2013:

Task 22, Final CNC Mill Spindle Holder

Log:

Made a trial bed using some scrape plastic broad. The broad was cut down to a size 200 mm by 200 mm broad. Reprint of the cnc spindle holder fail Extruder heat-end issues

Aug 15, 2013:

Task 21, Final CNC Mill Spindle Holder

Log:

- Giving the piece a smooth finished look by wiping down the piece with a cloth soaked with Acetone.

- Better methods are explained by the videos below

|

|

- Giving 3D printed parts a shiny smooth finish

|

|

Aug 14, 2013:

Task 21, End Mill BOM

Log:

Update HydraFabber BOM to include End Mill BOM

- Link to End Mill BOM

- Updated HydraFabber CNC Mill Spindle BOM

Aug 13, 2013:

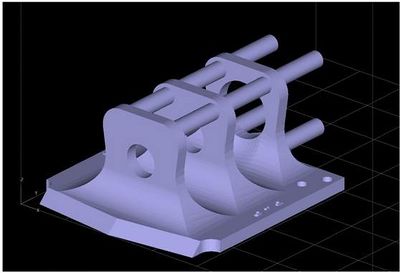

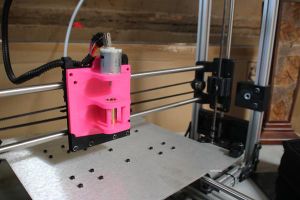

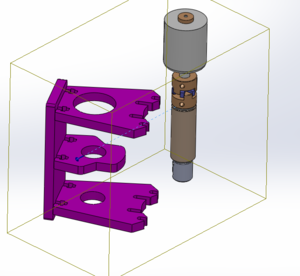

Task 20, Start of Final Build Cycle of CNC Mill Spindle Holder

Log:

- Transitioning to Final Build Cycle Of CNC Mill Spindle Holder Has Began.

- ETA is 15hrs, from 7:00pm CST to 10:00am CST Aug 14th.

- Cheers OSE, Team HydraFabber and All well wishes.

- ETA is 15hrs, from 7:00pm CST to 10:00am CST Aug 14th.

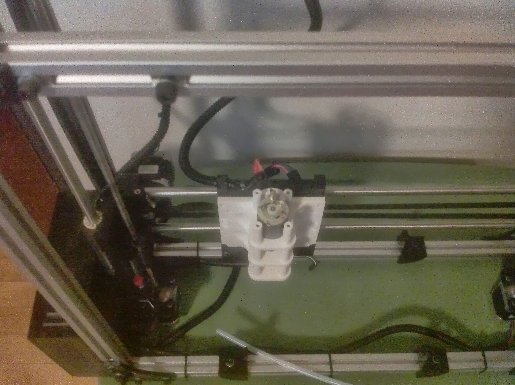

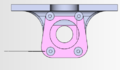

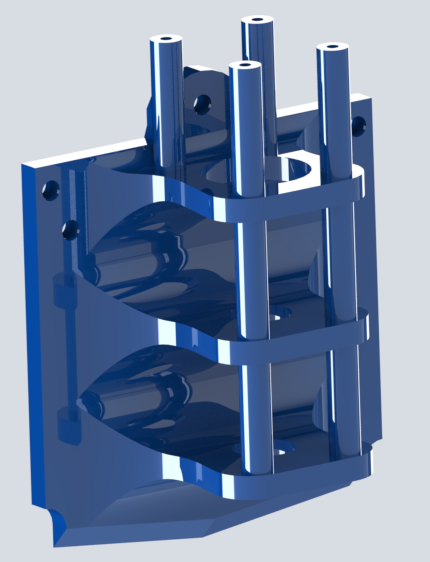

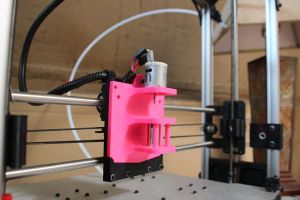

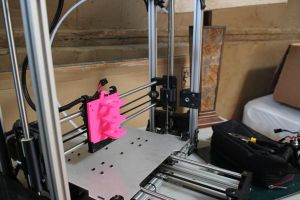

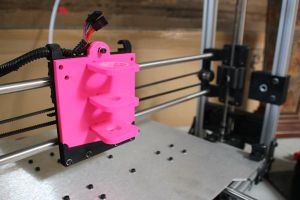

Some pix while we wait.

|

|

Files for HydraFABBER CNC Mill Spindle Holder:

File:Cnc mill spindle holder.SLDPRT, File:Cnc mill spindle holder.stl,

File:Cnc mill spindle holder.STEP and File:Cnc_mill_spindle_holder.gcode

Aug 13, 2013:

Exploring Metal Resources in Ghana.

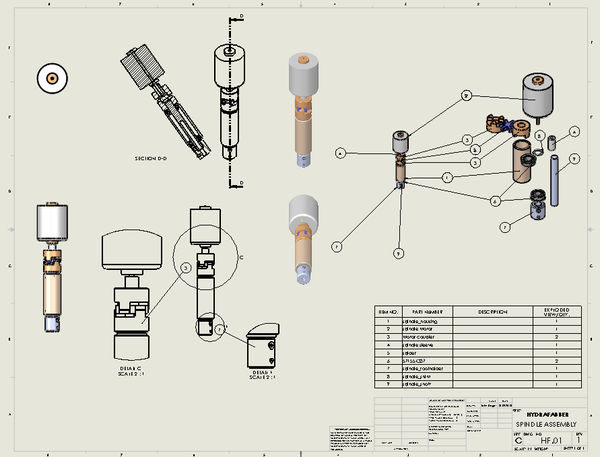

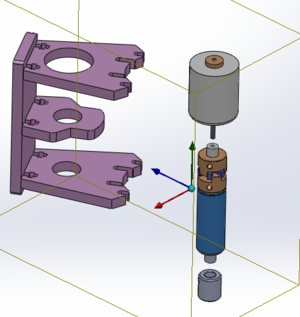

Task 19, Update of Spindle assembly drawing, exploded views and movie

Log:

|

Spindle Assembly Animation |

Aug 12, 2013:

Task 18, Spindle assembly drawing, exploded views and movie

Log:

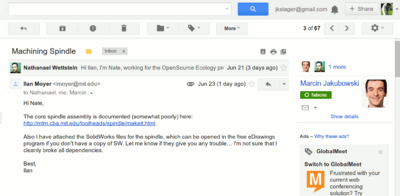

- End Mills for HydraFabber were ordered. ETA is Aug 15th 2013. Updated HydraFabber CNC Mill Spindle BOM

- Ilan Moyer comments on milling bits used: I don't have good data on this because I usually am milling circuit boards (copper-clad plastic) with a 1/32" or 1/64" end mill at around 10in/min and a depth of 0.006". However I have cut plywood with a 3/32" cutter at around the same speed and a depth of maybe 0.05." You can see that I've only done pretty light milling. A friend of mine has used the same spindle to mill steel, but very slowly with very shallow passes.

Aug 10, 2013:

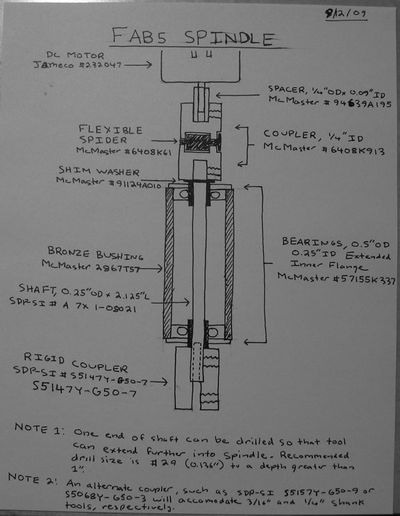

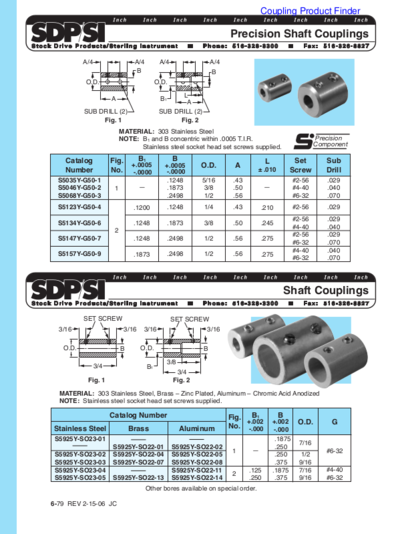

Task 17, Questions posed to IIan Moyer about shaft and coupler mating

Log:

- What was the solution for mating 6061K107 (Hardened Precision Steel Shaft 1/4" OD, 10" Length) with S51CAYM050050 (1 RIGID COUPLING WITH BoreS OF 5(H7) / 5(H7)MM ON OPPOSITE SIDES )?

- The shaft is larger than coupler bores. Can we assume that the coupler was drilled larger to accommodate the shaft. Verse grinding the shaft down to fit the coupler?

- If the coupler was drilled how precise was the enlargement?

Solution.

- Corrected BOM to reflect the correction.

SDP-SI A 7X 1-08021 1 Shaft, 0.2497"ODx2.125"L $2.63 $2.63

S5147Y-G50-7 1 Shaft Coupler, 0.125" Bore $10.95 $10.95 Other bore sizes avaliable.

S5157Y-G50-9 1 Shaft Coupler, 0.125" Bore $10.95 $10.95 ***alternate coupler

S5068Y-G50-3 1 Shaft Coupler, 0.125" Bore $8.22 $8.22 ***alternate coupler

| S5147Y-G50-7 | S5157Y-G50-9 | S5068Y-G50-3 |

Aug 9, 2013:

Task 16, Researched End mills and also fixed error from McMaster order

Log:

End mills. I believe 1/8 endmill from onsrud.com can be replaced with Part Number: 0.1250" DIA 2FL SE AlTiN 1/8 from http://www.carbidedepot.com/detail.aspx?ID=180149

Some Information about End Mills (Rotational Cutters) for CNC Machines

http://buildyourcnc.com/endmills.aspx

Store Front > "65-013" > 65-013 (Series 65-000 )

1/8" Solid Carbide One Flute Upcut Super O Flute for Plastic, Wood, Aluminum, Solid Surface

Series 65-000 Item # 65-013 Available? yes Price $34.90 As of 08/06/2013 19:00

http://www.carbidedepot.com/detail.aspx?ID=180149

Part Number: 0.1250" DIA 2FL SE AlTiN 1/8

Product ID: CU 130051

Sold in packs of: 1

Manufacturer: CARBI-UNIVERSAL Sale Price $13.88 $6.73 (Savings: $7.15) Description: COATED CARBIDE ENDMILL 1/2" LOC - 1-1/2" OAL - 1/8" SHK DIA

Availability: CARBIDE DEPOT STOCK ITEM - USUALLY SHIPS SAME DAY

http://www.carbidedepot.com/detail.aspx?ID=70452

Part Number: 0.0100" DIA 220M .010

Product ID: GT 11550

Sold in packs of: 1

Manufacturer: GARR TOOL Sale Price $18.89 $16.43 (Savings: $2.46) Description: .010" EM SQ 2FL S/E SMG - 0.03" LOC - 1.5" OAL

Availability: USUALLY SHIPS SAME DAY OUT OF MICHIGAN

http://www.carbidedepot.com/detail.aspx?ID=180142

Part Number: 0.0156" DIA 2FL SE AlTiN 1/64

Product ID: CU 129974

Sold in packs of: 1

Manufacturer: CARBI-UNIVERSAL Sale Price $30.52 $14.80 (Savings: $15.72) Description: COATED CARBIDE ENDMILL 1/32" LOC - 1-1/2" OAL - 1/8" SHK DIA

Availability: CARBIDE DEPOT STOCK ITEM - USUALLY SHIPS SAME DAY

http://www.carbidedepot.com/detail.aspx?ID=180143

Part Number: 0.0312" DIA 2FL SE AlTiN 1/32 Product ID: CU 129985 Sold in packs of: 1

Manufacturer: CARBI-UNIVERSAL Sale Price $20.62 $10.00 (Savings: $10.62) Description: COATED CARBIDE ENDMILL 1/8" LOC - 1-1/2" OAL - 1/8" SHK DIA

Availability: CARBIDE DEPOT STOCK ITEM - USUALLY SHIPS SAME DAY

TOOLS

http://www.mcmaster.com/#catalog/119/2811/=nznzr9 ( tool# 57185A22 qty: 1 )

http://www.mcmaster.com/#catalog/119/2805/=nznzw6 ( tool# 7122A12 qty: 3 )

Aug 8, 2013:

Task 15, RE-FLASHING YOUR 3D PRINTER'S FIRMWARE

Log:

- Arrival of SDP/SI's pieces(check BOM)

- Min Temp Extruder Error Issue resolved by re-flashing the Taz Firmware.

Files

Aug 7, 2013:

Task 14, Reprinted spindle holder with modifications after Test 1

Log:

- Arrival of McMaster's pieces(check BOM)

- Reprinted spindle holder with modifications

Files

File:CarriageAssemblyPart fixed.stl

Aug 5-6, 2013:

Task 13, Software and spindle holder Test 1 under working conditions

Log:

Fundamental pieces of software required to run the Taz.

- Arduino software: this application allows you to install the printer firmware onto the ATMega microprocessor. This installation is required each time you want to update the firmware.

- Firmware: there are several firmwares available for RepRap printers. The firmware is installed on the ATMega microprocessor and handles the G-code instructions received from the PC. Part of the configuration of the printer has to be done in the firmware.

- Skein software: the most popular application to slice STL files into G-code is called Skeinforge. You need this piece of software each time you want to print a part.

- Host software: there are also several host application available for RepRap printers. This application is responsible for communicating with the electronics of the printer before and during print jobs. It prepares the printer before starting a print job and then also starts the actual print jobs.

Aug 3, 2013:

Task 12, HydraFabber CNC Mill Spindle Mechanical Ordered

HydraFabber CNC Mill Spindle Mechanical BOM was ordered Aug 2 2013 and we are waiting for their arrival

Progress

Aug 1-2, 2013:

Task 11, Progress report

Log:

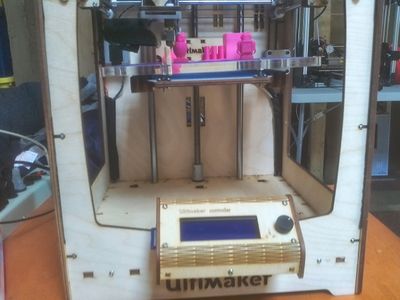

- Samples of the printed CNC Mill Spindle Holder

Mon Jul 29, 2013:

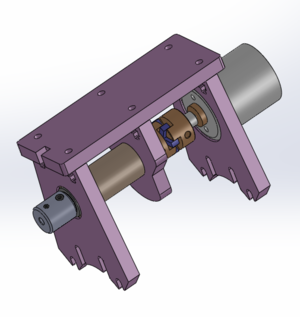

Task 10, HydraFabber X Carriage and X Carriage-FQ (female quick attach)

Log:

Taz X Carriage and X Carriage-FQ (female quick attach) were converted to .stl from freecad. They will be used in modeling the new cnc-mill spindle holder with a quick attach.

File:Taz-X-Carriage.STL File:Taz-X-Carriage-FQ.STL

July 26-29, 2013:

Task 9, Current State July 2013 & DPAI Current State July 2013 Matrix

Log:

- Worked on Current State July 2013 and DPAI Current State July 2013 Matrix with current DPVs and OSE Staff.

- Provided insights as Remote Contributor and DPV to standardize the GVCS build process.

Thurs July 25, 2013:

Task 8, Setup 3D Printing System for Linux(Ubuntu 12.04)

Log:

Installed: Ubuntu 12.04, Python 2.7, Cura/Replcatorg/Pronterface/Printrun/Slic3r

Printers were not able to connect to printers. This was fixed using the resources below. RepRap IRC

- [13:01] <stager_> how do I connect to either ultimaker or lulzbot taz with ubuntu 12.04#

- [13:01] <ScribbleJ> Use Pronterface.#

- [13:01] <stager_> I get connection timed out when I try to connect to either printer#

- [13:02] <teepee> check if your user is in group dialout#

- [13:02] <iXce> are you specifying the right baudrate ?#

- [13:02] <iXce> that too#

- [13:02] <teepee> right if baudrate is 250000, that might be a bit problematic...#

- [13:03] <teepee> 250000?##

- [13:03] <kthx> 250000 is problematic on linux, see https://github.com/ErikZalm/Marlin/issues/205 for some details about the problem and is also possible with a patch to pyserial, see https://groups.google.com/d/msg/ultimaker/BNjPpoJpfrE/gGSKAdhY5VwJ#

- [13:03] <stager_> yes 250000 baudrate for ultimaker and 112500 for lulzbot taz#

This is the fix by Martin Renold :The Fix Patch

THANKS to Martin Renold

Thanks for pointing this patch out, I've just upgraded my baudrate now.

I think the better way to install is:

- svn co http://pyserial.svn.sourceforge.net/svnroot/pyserial/trunk pyserial #

- cd pyserial #

- patch -p0 < ../pyserial.patch #

- cd pyserial #

- cd pyserial #

- python setup.py install --user #

- python3 setup.py install --user #

So the next distro upgrade won't override your local version.

Wed Jul 24, 2013:

Task 7 Work plan for getting CNC Circuit Mill Spindle working on TAZ:

Log:

- Document final BOM including spindle motor, bit holder, bearings.

- Embeded Google Spreadsheet for HydraFabber CNC Mill Spindle BOM to OSE Wiki

- Added an Edit link at the bottom of the embedded Google Spreadsheet

- Generate exploded part diagram in Sketchup or Solidworks referencing numbered items in BOM spreadsheet

- Verify and purchase parts

- Prepare and avail all the files for the spindle holder. Upload to wiki.

- STL file

- RAMPS gcode file

- Let the RepRap IRC know about this, and let Marcin know that we can add printing file and Spindle BOM to a blog post - to encourage others to develop the CNC Circuit Mill in parallel.

- Print Spindle Holder

- Secure a 5V power source

- Take photo and document all spindle parts and when you build it, do a Dozuki build procedure.

- Build out spindle, connect spindle motor to power, install an on-off switch for mill

- Source proper milling bits and buy them

- Prepare a milling bed - 1/4" plywood taped down.

- Level the milling bed

- Whenever you have free time, reach to RepRap IRC for code for milling on a RAMPS system, or search web

- Document all the examples you find on this - write down links

- Download CNC mill software and upload to OSE wiki

- Determine a strategy for uploading CNC Milling code to existing TAZ

- Use a different Arduino/RAMPS? Upload new software/firmware

- Document your path before making any changes.

July 20, 2013:

Task 6, Setup 3D Printing System for MS Windows

Log:

Windows 7, Python 2.7, Cura/Replcatorg/Pronterface/Printrun/Slic3r

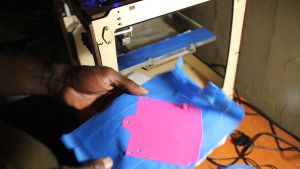

The rest of the images are here [1]

July 12, 2013:

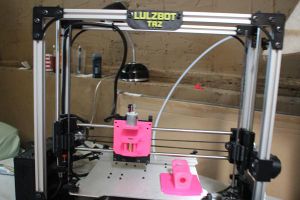

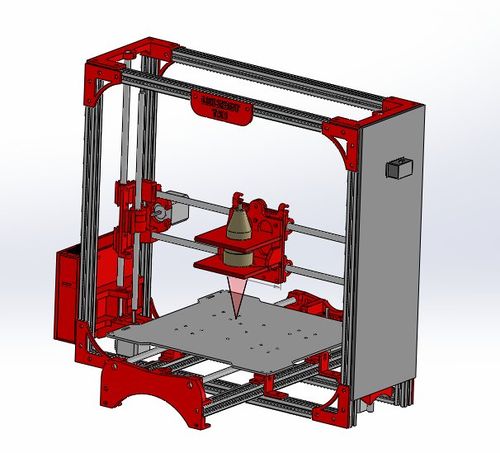

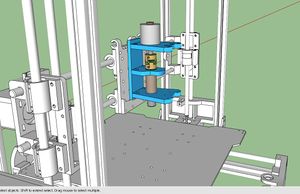

Task 5, Taz with Laser and CNC Circuit Mill Spindle aka HydraFabber

Log:

Incorporated Diode laser from Tim Log.

Files for HydraFABBER:

File:HydraFABBER.SLDASM, File:HydraFABBER.stl and File:HydraFABBER.STEP.zip

June 25, 2013:

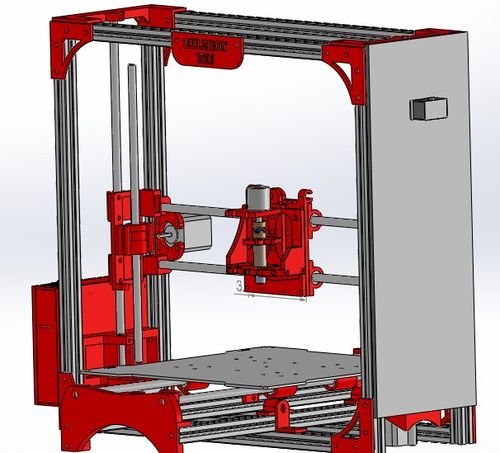

Task 4, Lulzbot Taz with CNC Circuit Mill Spindle

Log:

Files for Lulzbot Taz & Spindle Assembly:

File:Lulzbot n Spindle1.skp and File:Spindle Assembly.skp

June 24, 2013:

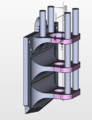

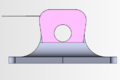

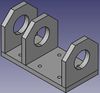

Task 3, CNC Circuit Mill Spindle

Log:

Remachined Spindle Assembly Files:

Remachined Spindle Files from Ilan Moyer

Original SolidWorks File:Remachiningspindle.zip Convert to File:Spindle assy.stp

June 23, 2013:

Task 2, CNC Circuit Mill Spindle

Goal

- Mount the existing CNC Circuit Mill Spindle by MIT on to the TAZ's Carriage attachment

Log Spindle in FreeCAD

Convert spindle Solidworks files to Sketchup

Drafts of spindle mount:

Files for Spindle Assembly:

- Spindle file from via RTENOTITLE from Solidworks into STP: File:Spindle assy.stp

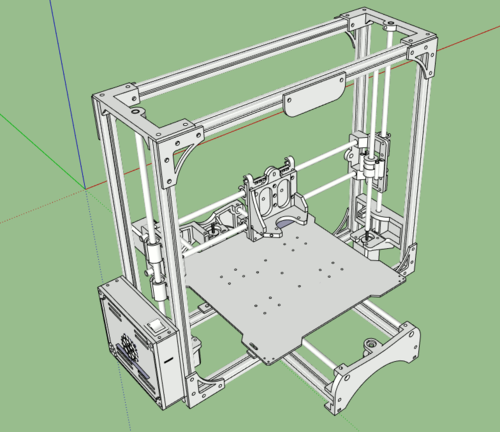

June 22, 2013:

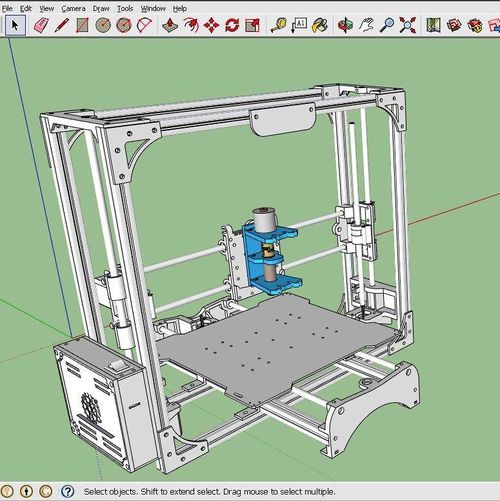

Task 1, LulzBot TAZ

Convert Taz FreeCAD files to Sketchup

Incorporated and continuing from Nate Log.

Basic Idea: Incorporate Carriage with X_MillSpindleMount. Spindle mount is removable, so we can also mount the laser diode head.

Goal:

Find relevant TAZ parts. Convert TK0_Assembly.fcstd To Sketchup. Make groups, components and cleanup Taz sketchup file.

Log:

Files for Lulzbot:

- SKETCHUP file for Lulzbot TAZ -File:Lulzbot.skp http://opensourceecology.org/wiki/File:Lulzbot.skp

- CAD files in FreeCAD. Part files for Lulzbot TAZ - http://download.lulzbot.com/TAZ/hardware/printed_parts/

- the FreeCAD files are here http://download.lulzbot.com/TAZ/hardware/printed_parts/FreeCAD/

- OpenSCAD files for TK-0, the former name of TAZ - https://github.com/mswillia/TK-0

- Please coordinate between John Log, Leo Log, Tim Log, and Nate Log - all work related to HydraFabber.