Charcoal Gasifier: Difference between revisions

Jump to navigation

Jump to search

(Created page with " <html> <iframe width="560" height="315" src="https://www.youtube.com/embed/1gmg_Uuz5Ps" frameborder="0" allowfullscreen></iframe> </html> ==Related Pages== * Compressed F...") |

(Saved Progress Mid-Long Edit) |

||

| (13 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

=Basics= | |||

*There are some advantages with using charcoal (rather than wood) for gasification (section taken from: [[Troy Martz Gasifier]]). These may include: | |||

**Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours. | |||

**The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for [[biochar]]...what a great byproduct to have | |||

**We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and dust…easily done. | |||

**Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass. | |||

**We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “Imbert” design | |||

**We can scale gas production with the same system by merely swapping out a single nozzle size – we can go from 2kW to 50kW with the same machine! | |||

**Yes, charcoal has less BTU’s, but we can also utilize those BTU’s by capturing and using that heat with a smart charcoal retort design | |||

**Charcoal gasifiers have the potential to produce far more powerful gas flow than biomass gasifiers... Cracking steam is the key. | |||

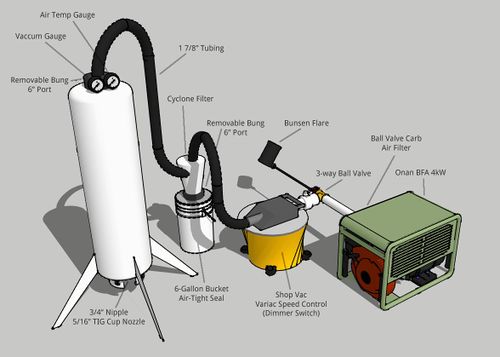

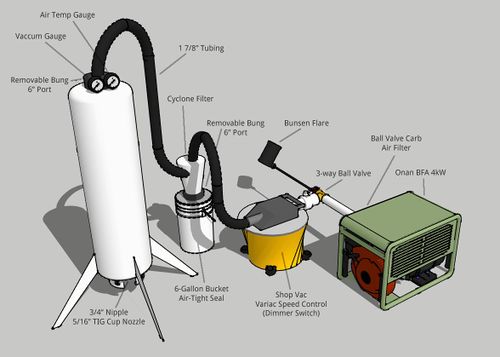

[[Image:troygas1.jpg|thumb|right|500px|[[Troy Martz Gasifier]] - gasifies charcoal ]] | |||

=Videos= | |||

<html> | <html> | ||

| Line 5: | Line 18: | ||

</html> | </html> | ||

== | =Existing DIY/OS Designs= | ||

* [[ | == [[Greenhill Forge (YouTube Channel) ]] 's Design == | ||

* [[ | *[https://youtu.be/nXEDKRbiJe4?si=Uq6vTKYDC67IpmJ7 A Video by the YouTube Channel "Greenhill Forge" Titled "Building a Simple Gasifier: FREE Engine Fuel from Charcoal" ] ( '''~25 Minute Watch''' ) | ||

* [[ | ***Need to check with them if it's okay, but they have some GREAT infographics ~[https://youtu.be/nXEDKRbiJe4?si=HBL6sLJsmxUvDgXD&t=234 3:54] | ||

* [[ | ***Also [https://youtu.be/nXEDKRbiJe4?si=j406zcUhq-zQo_uX&t=50 0:55 Safety Note was Apt] | ||

****"If you decide to experiment with gasification, please remember that it is LITERALLY a [[Carbon Monoxide]] making machine, and it can be extremely dangerous, so make sure you know what you are doing and do it safely | |||

****Uncertain on if [[SynGas]] has any [[Methane]] in it, but minor mistake / that may be an unintentional product infrequently mentioned in giant plant designs etc | |||

****I know [[Wood Gas]] / [[Pyrolysis Gas]] does tend to contain all sorts of gas species | |||

===Design Overview=== | |||

*It is a [[Crossdraft Gasifier]] | |||

====Notes Taken by [[User: Eric]] while (re-)watching the video==== | |||

*Made largely of welded together steel | |||

*Uninsulated (Unlike the current OSE Design which uses a [[Fire Brick]] Hearth) | |||

*It was made using a [[CNC Plasma Cutter]] , thus Files exist somewhere | |||

*[[Intermittent Fillet Welds]] were used | |||

*A Truncated U Shape is made over the [[Ash Grate]] to confine the reaction to a narrower space (presumably to follow the zone interacting with the air, almost the inverse of the "Dead Man" in [[Blast Furnaces]] ) | |||

*Oversized Inlet and Outlet Pipes (No exact dimensions mentioned) | |||

*Only a linear (forward and backward) [[Ash Shaker]] , will be interesting to see if that will clog up or not | |||

**Largely depends on the [[Ash Content]] of the [[Charcoal]] , and the Hardness of the Shaker Grate? (ie can it grind up + "eat" the [[Bottom Ash]] / [[Clinker]] ) | |||

***In terms of [[Design for Cleaning]] , making that part easily accessible may be worthwhile) | |||

*Hinged Lid Reinforced with Square Tubing, and has a Gasket + Spring Latch | |||

*[[Adhesive Fire Rope]] mentioned as a Gasket Material | |||

*3 Thermocouples "Stabbed In" (After being predrilled) and sealed with [[RTV Silicone]] | |||

**A more robust solution may be warranted for LONG TERM use (ie if/WHEN a probe fails, and needs replaced etc), but for an experimental setup this is fine | |||

*It then goes to a [[Cyclonic Filter]] | |||

*Neat [[Gas Flare]] made using a standard [[Soup Can]] and Steel Tubing | |||

**As per that [[Landfill Gas]] paper, probably the Chandelier Type? (Double Check This) | |||

*Need to check an older video (with their albeit far more novel Charcoal Retort]] , but it seems this design DOES use [[Screened Charcoal]] | |||

**Seems to be a [[Trommel]] of Welded Wire Mesh, akin to that used for fencing | |||

*Exhaust Blower On + a [[Blowtorch]] put in the inlet for start | |||

**10-30 Second Startup until Self Sustaining Flare Flame | |||

*Fuel Tank Removed from Engine, Engine Adapted to [[Drill Engine Starter]] , Fuel Line Capped Off, Carburetor / Throttle Body/ Fuel Assembly left in place as an easier experimental setup for that, dedicated replacement can be done later down the line | |||

*A standard [[T-Fitting]] and [[Butterfly Valve]] (Neat DIY/OS Design using PVC Pipe made) is made for regulating [[Air-Fuel Mixture]] | |||

**Flashback Arrestors / Explosion Proofing, or at least Leak Monitoring may be warranted on this side, has my safety spidey senses tingling a bit | |||

*An [[Air Filter Sponge]] is used, some sort of 3D Printed / CNC Milled adapter to either the standard String Trimmer/Chainsaw Filters, or a larger filter (Could be identical to HVAC and/or Car+Truck etc for [[Parts Reduction]] + Making Stockpiles of [[Spare Parts Inventory]] more useful etc) would probably be a better end goal solution | |||

*A [[Sawdust Air Filter]] made from a [[Open Head Plastic Drum]] (30 Gallon Maybe?) is used AFTER the Blower/Flare Stack, but before the engine | |||

**CAN work, but leaves one to wonder on Blower Durability, most are air cooled, and as with [[Vacuum Cleaner Pre-Motor Filters]] keeping a blower as clean as possible is best practice | |||

***Frequent Enough Removal + Servicing could PROBABLY suffice, and again this is an experimental setup, not a power plant!, still just documenting thoughts | |||

*They noted Corrosion in the Heart, possibly due to an Oversized Reduction Zone (Thus syngas flowing by not doing anything, cooling down/condensing + causing corrosion) | |||

**[[Syngas Filtration]] / [[Syngas Upgrading]] including Water Vapor Removal is worth investigating | |||

**Having a [[Thermometer-Hydrometer]] (Assuming they can be operated in an Atmosphere of Syngas, and do so without exploding etc) inline may aid in troubleshooting | |||

*ALL IN ALL great design! | |||

====Thoughts/Ideas On It==== | |||

*I'll have to go check out the OSE Design; they look similar in overall form, but may have different internals and whatnot | |||

*Materials Science nerd me wonders if having it be CO-rich, [[Hydrogen]] -lean would be beneficial for Leak Detection + Reducing [[Hydrogen Embrittlement]] etc | |||

**Granted the adding water/steam basically turns [[Waste Heat]] into "Free" Power, right? | |||

**Granted it would add to [[Ash Content]] / clogging issues and POTENTIALLY add all sorts of problems, but using this as a way to Evaporate/Destroy [[Greywater]] etc would be neat (Although assuming Freshwater isn't scarce locally it shouldn't be that big of a deal | |||

**[[Exhaust Gas Water Recovery]] would be interesting to look into as well, if using a [[Rocket Mass Heater]] type mechanism to cool exhaust gas + a basic [[Dehumidifier]] (ESPECIALLY a [[Rotary Desiccant Wheel Dehumidifier]] ) | |||

**Granted more parasitic load there eric! | |||

*MORE SENSORS | |||

**Granted [[Intrinsically Safe]] / [[Explosion Proof]] Concerns there | |||

**Also, as with many Modern Cars etc, this can lead to an issue of "What would have been "business as usual" before (No sensor, but operating fine), is now a repair need (Sensor Broken/Faulty->Please Troubleshoot) | |||

***LUCKILY with [[Design for Repair]] / [[Design for Cleaning]] and all that, it SHOULD be a matter of remove it + put a new sensor from the spare bin in | |||

****Also how much does each temp probe cost etc 10-40USD maybe, above that it starts getting a bit much | |||

****Granted all relevant on how giant/important of aa build it will be/how long they last for ("Buy Once, Cry Once. [[Buy Cheap, Buy Twice]] " etc) | |||

*I do think a [[Fire Brick]] / [[Refractory]] Lining would help. Designing it such that it slides in and is held in by slots, or is Interlocking Bricks would be nice for a [[Design for Repair]] / [[Design for Cleaning]] perspective (ie don't grab an [[SDS Drill]] / turn the whole thing to rubble/scrap metal, just remove the sacrificial layer and resume | |||

**I still haven't found a Refractory Material i LOVE from an [[Appropriate Materials]] perspective, but Firebrick / some rated mortar etc isn't HORRIBLE (again, need to check out the OSE Design) | |||

*In terms of Charcoal Size, would powder/1cm chunks work well, or no? | |||

**Thinking More Surface Area = More Gas, granted do larger chunks/pellets help with air flow, anything smaller would be too clogging? | |||

*A [[Rotary Airlock]] or other means to Refill While Running would also be nice | |||

**A "Knife Gate" and airtight lid may work a la those Wood Chip Boilers | |||

*Some means to view Fuel Level (Short of it burns X Liters of Charcoal per Hour, thus we should add another bucket in an hour" type [[Dead Reckoning]] would be nice ) | |||

**A [[Sapphire Watch Glass]] Based [[Sight Glass]] (ie one port up top, one just above the hot zone/one in the hot zone, keep it above the line and you're good) | |||

= | =Internal Links= | ||

* | *[[Gasifier 3D CAD]] (For OSE’s Latest Design) | ||

* | *[[Compressed Fuel Gas]] | ||

* | *[[Troy Martz Gasifier]] - gasifies charcoal | ||

* | *[[Biomass to Fuel]] | ||

*[[The Biochar Economy]] and [[Kon-Tiki Kiln]] | |||

=External Links= | |||

*[http://www.fao.org/docrep/T0512E/T0512e07.htm "Small wood and charcoal gasifiers for operation of internal combustion engines"] | |||

*[http://www.instructables.com/id/Charcoal-Fire-Powered-Generator/ An Instructable by "fjrgjgr" Titled "Charcoal Powered Generator - Gasifier" ] | |||

*[http://www.permies.com/t/19954/energy/Charcoal-Gasification A Permies . com Forum Post on Charcoal Gasification] | |||

*[http://gasifiers.bioenergylists.org/type/charcoal-gasifier The Bioenergylists Page on Charcoal Gasifier Designs] | |||

[[Category: | [[Category:Biofuel]] [[Category:Energy]] | ||

[[Category:Energy]] | |||

Latest revision as of 21:56, 12 October 2025

Basics

- There are some advantages with using charcoal (rather than wood) for gasification (section taken from: Troy Martz Gasifier). These may include:

- Sufficiently drying wood/biomass to an appropriate water content % takes days. Charcoal can be made and used in mere hours.

- The byproduct of charcoal sizing (anything under 1/16th of an inch) just happens to be perfectly sized for biochar...what a great byproduct to have

- We don’t have to worry about tar! Thus, filtration in the down line is relegated to ash and dust…easily done.

- Pure carbon is a perfect catalyst for the reduction process… You never really get 100% there with biomass.

- We eliminated “pyrolysis” from the problem we’re trying to solve, so the gasifier design becomes infinitely more flexible than the “Imbert” design

- We can scale gas production with the same system by merely swapping out a single nozzle size – we can go from 2kW to 50kW with the same machine!

- Yes, charcoal has less BTU’s, but we can also utilize those BTU’s by capturing and using that heat with a smart charcoal retort design

- Charcoal gasifiers have the potential to produce far more powerful gas flow than biomass gasifiers... Cracking steam is the key.

Troy Martz Gasifier - gasifies charcoal

Videos

Existing DIY/OS Designs

Greenhill Forge (YouTube Channel) 's Design

- A Video by the YouTube Channel "Greenhill Forge" Titled "Building a Simple Gasifier: FREE Engine Fuel from Charcoal" ( ~25 Minute Watch )

- Need to check with them if it's okay, but they have some GREAT infographics ~3:54

- Also 0:55 Safety Note was Apt

- "If you decide to experiment with gasification, please remember that it is LITERALLY a Carbon Monoxide making machine, and it can be extremely dangerous, so make sure you know what you are doing and do it safely

- Uncertain on if SynGas has any Methane in it, but minor mistake / that may be an unintentional product infrequently mentioned in giant plant designs etc

- I know Wood Gas / Pyrolysis Gas does tend to contain all sorts of gas species

Design Overview

- It is a Crossdraft Gasifier

Notes Taken by User: Eric while (re-)watching the video

- Made largely of welded together steel

- Uninsulated (Unlike the current OSE Design which uses a Fire Brick Hearth)

- It was made using a CNC Plasma Cutter , thus Files exist somewhere

- Intermittent Fillet Welds were used

- A Truncated U Shape is made over the Ash Grate to confine the reaction to a narrower space (presumably to follow the zone interacting with the air, almost the inverse of the "Dead Man" in Blast Furnaces )

- Oversized Inlet and Outlet Pipes (No exact dimensions mentioned)

- Only a linear (forward and backward) Ash Shaker , will be interesting to see if that will clog up or not

- Largely depends on the Ash Content of the Charcoal , and the Hardness of the Shaker Grate? (ie can it grind up + "eat" the Bottom Ash / Clinker )

- In terms of Design for Cleaning , making that part easily accessible may be worthwhile)

- Largely depends on the Ash Content of the Charcoal , and the Hardness of the Shaker Grate? (ie can it grind up + "eat" the Bottom Ash / Clinker )

- Hinged Lid Reinforced with Square Tubing, and has a Gasket + Spring Latch

- Adhesive Fire Rope mentioned as a Gasket Material

- 3 Thermocouples "Stabbed In" (After being predrilled) and sealed with RTV Silicone

- A more robust solution may be warranted for LONG TERM use (ie if/WHEN a probe fails, and needs replaced etc), but for an experimental setup this is fine

- It then goes to a Cyclonic Filter

- Neat Gas Flare made using a standard Soup Can and Steel Tubing

- As per that Landfill Gas paper, probably the Chandelier Type? (Double Check This)

- Need to check an older video (with their albeit far more novel Charcoal Retort]] , but it seems this design DOES use Screened Charcoal

- Seems to be a Trommel of Welded Wire Mesh, akin to that used for fencing

- Exhaust Blower On + a Blowtorch put in the inlet for start

- 10-30 Second Startup until Self Sustaining Flare Flame

- Fuel Tank Removed from Engine, Engine Adapted to Drill Engine Starter , Fuel Line Capped Off, Carburetor / Throttle Body/ Fuel Assembly left in place as an easier experimental setup for that, dedicated replacement can be done later down the line

- A standard T-Fitting and Butterfly Valve (Neat DIY/OS Design using PVC Pipe made) is made for regulating Air-Fuel Mixture

- Flashback Arrestors / Explosion Proofing, or at least Leak Monitoring may be warranted on this side, has my safety spidey senses tingling a bit

- An Air Filter Sponge is used, some sort of 3D Printed / CNC Milled adapter to either the standard String Trimmer/Chainsaw Filters, or a larger filter (Could be identical to HVAC and/or Car+Truck etc for Parts Reduction + Making Stockpiles of Spare Parts Inventory more useful etc) would probably be a better end goal solution

- A Sawdust Air Filter made from a Open Head Plastic Drum (30 Gallon Maybe?) is used AFTER the Blower/Flare Stack, but before the engine

- CAN work, but leaves one to wonder on Blower Durability, most are air cooled, and as with Vacuum Cleaner Pre-Motor Filters keeping a blower as clean as possible is best practice

- Frequent Enough Removal + Servicing could PROBABLY suffice, and again this is an experimental setup, not a power plant!, still just documenting thoughts

- CAN work, but leaves one to wonder on Blower Durability, most are air cooled, and as with Vacuum Cleaner Pre-Motor Filters keeping a blower as clean as possible is best practice

- They noted Corrosion in the Heart, possibly due to an Oversized Reduction Zone (Thus syngas flowing by not doing anything, cooling down/condensing + causing corrosion)

- Syngas Filtration / Syngas Upgrading including Water Vapor Removal is worth investigating

- Having a Thermometer-Hydrometer (Assuming they can be operated in an Atmosphere of Syngas, and do so without exploding etc) inline may aid in troubleshooting

- ALL IN ALL great design!

Thoughts/Ideas On It

- I'll have to go check out the OSE Design; they look similar in overall form, but may have different internals and whatnot

- Materials Science nerd me wonders if having it be CO-rich, Hydrogen -lean would be beneficial for Leak Detection + Reducing Hydrogen Embrittlement etc

- Granted the adding water/steam basically turns Waste Heat into "Free" Power, right?

- Granted it would add to Ash Content / clogging issues and POTENTIALLY add all sorts of problems, but using this as a way to Evaporate/Destroy Greywater etc would be neat (Although assuming Freshwater isn't scarce locally it shouldn't be that big of a deal

- Exhaust Gas Water Recovery would be interesting to look into as well, if using a Rocket Mass Heater type mechanism to cool exhaust gas + a basic Dehumidifier (ESPECIALLY a Rotary Desiccant Wheel Dehumidifier )

- Granted more parasitic load there eric!

- MORE SENSORS

- Granted Intrinsically Safe / Explosion Proof Concerns there

- Also, as with many Modern Cars etc, this can lead to an issue of "What would have been "business as usual" before (No sensor, but operating fine), is now a repair need (Sensor Broken/Faulty->Please Troubleshoot)

- LUCKILY with Design for Repair / Design for Cleaning and all that, it SHOULD be a matter of remove it + put a new sensor from the spare bin in

- Also how much does each temp probe cost etc 10-40USD maybe, above that it starts getting a bit much

- Granted all relevant on how giant/important of aa build it will be/how long they last for ("Buy Once, Cry Once. Buy Cheap, Buy Twice " etc)

- LUCKILY with Design for Repair / Design for Cleaning and all that, it SHOULD be a matter of remove it + put a new sensor from the spare bin in

- I do think a Fire Brick / Refractory Lining would help. Designing it such that it slides in and is held in by slots, or is Interlocking Bricks would be nice for a Design for Repair / Design for Cleaning perspective (ie don't grab an SDS Drill / turn the whole thing to rubble/scrap metal, just remove the sacrificial layer and resume

- I still haven't found a Refractory Material i LOVE from an Appropriate Materials perspective, but Firebrick / some rated mortar etc isn't HORRIBLE (again, need to check out the OSE Design)

- In terms of Charcoal Size, would powder/1cm chunks work well, or no?

- Thinking More Surface Area = More Gas, granted do larger chunks/pellets help with air flow, anything smaller would be too clogging?

- A Rotary Airlock or other means to Refill While Running would also be nice

- A "Knife Gate" and airtight lid may work a la those Wood Chip Boilers

- Some means to view Fuel Level (Short of it burns X Liters of Charcoal per Hour, thus we should add another bucket in an hour" type Dead Reckoning would be nice )

- A Sapphire Watch Glass Based Sight Glass (ie one port up top, one just above the hot zone/one in the hot zone, keep it above the line and you're good)

Internal Links

- Gasifier 3D CAD (For OSE’s Latest Design)

- Compressed Fuel Gas

- Troy Martz Gasifier - gasifies charcoal

- Biomass to Fuel

- The Biochar Economy and Kon-Tiki Kiln