Torrefaction: Difference between revisions

Jump to navigation

Jump to search

(Added some more links under the "External Links" section) |

(Added some more information) |

||

| Line 13: | Line 13: | ||

**Improved grindability. | **Improved grindability. | ||

**Seems to be via coating the resulting char in the tar via it not being extracted/removed in the flue gas? | **Seems to be via coating the resulting char in the tar via it not being extracted/removed in the flue gas? | ||

*Along with the products of [[Hydrothermal Carbonization]] , it is often referred to informally as [[Bio-Coal]] given it's similarities to [[Bituminous Coal]] / [[Sub-Bituminous Coal]] ( [[Lignite]] / [[Brown Coal]] ) | |||

=Internal Links= | =Internal Links= | ||

Latest revision as of 01:24, 26 May 2023

Basics

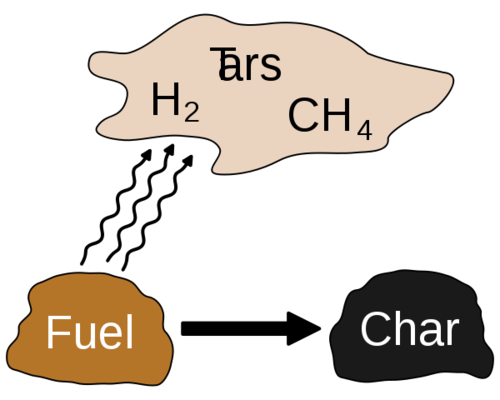

- A mild form of Biomass Pyrolysis at temperatures typically between 200 and 320 °C

- Produces mainly Tar , and Charcoal

- Can clog vents etc if not accounted for in design

- If intentional the calorific value of biomass can be greatly increased

- Benefits are:

- Higher energy density

- More homogeneous composition

- Hydrophobic behavior

- Elimination of biological activity

- Improved grindability.

- Seems to be via coating the resulting char in the tar via it not being extracted/removed in the flue gas?

- Along with the products of Hydrothermal Carbonization , it is often referred to informally as Bio-Coal given it's similarities to Bituminous Coal / Sub-Bituminous Coal ( Lignite / Brown Coal )

Internal Links

- Bio-Tar

- Bio-Asphalt

- Wood Preservation by Carbonization

- Pelletized biomass and Wood Chips

- Kon-Tiki Kiln and Biochar

External Links

- The Wikipedia Page on Torrefaction

- An Article by " The Coalition for Sustainable Rail " titled "Torrefied Biomass"

- An Article in Biomass Magazine Titled "Why Hasn’t Torrefaction Taken Off?" (Essentially an advertisement for " Advanced Torrefaction Systems LLC " , but interesting nonetheless)

- A 2021 Article in Frontiers in Energy Research: Bioenergy and Biofuels Titled "Torrefied Biomass and Where Is the Sector Currently Standing in Terms of Research, Technology Development, and Implementation"