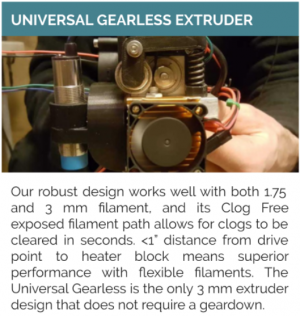

Universal Gearless Extruder

Intro

A Flexible Gearless Extruder is one of the distinguishing features of OSE's D3D Universal 3D printer, now introduced as the standard extruder for D3D Pro, Pro 2, and Pro 3.

OSE History

We have experimented with various extruder designs since 2016 - see 3D Printer Genealogy. We started with the common MK8 Extruder in 2016. The MK8 is a simple, gearless design, but it works only with 1.75 mm filament. Further, it is a design that one buys commonly off-the-shelf, and it requires some machining if one is to build it in a DIY fashion. Further, we could not find any well-documented, open source versions at the time. Given that the Prusa printers were exploding as a popular, open source brand at the time - we switched to the Prusa i3 MK2 Extruder. You can read more notes on our experience at Extruder Improvements from MK8 to Prusa i3 MK2 Extruder. We modified the Prusa i3 MK2 for a larger, 8-mm distance sensing probe - as we are interested in large prints and less risk of the height sensor hitting the prints. You can view our design details at Prusa i3 MK2 OSE Mod. While it seemed that the current, open source design from the most popular hobby printer company may be the best design - we found the choice to be terrible. We could not prevent the Prusa i3 MK2 from persistent clogging. The only way we succeeded was by disabling retraction all together, which meant lowering of print quality. This choice was particularly troubling because we ran a workshop in 2018 based on the Prusa extruder, leaving many of the participants frustrated. We switched to the E3D Titan Aero - the same as our poster-child Lulzbot 3D printer company was using in their more industrial-grade (compared to Prusa) printers. This change meant a switch to the most well-known, open source leader in 3D printer extruders - E3D. Lulzbot's Jeff Moe succeeded in getting E3D to open source their designs, which meant that we were consistent with our philosophy of using open source parts. Further, the Titan Aero was a decent design for printing with flexibles. Since OSE plans on 3D printing rubber tracks and sprockets for tractors, effective rubber printing is critical for OSE's industrial productivity on a small scale. The Titan Aero features an integrated hot end heat sink, meaning that the long, finned heat sink of the common E3D V6 or J-Head design is not needed. Simply put - E3D V6 or J-Head can't print efficiently in rubber: you have to slow the print rate way down in order to do it. The shorter the distance between the extryder drive gear and the heat break - the faster the print rate. The Titan Aero was the best 3 mm design for sub-industrial grade printers on the market at the time. See also Why 3mm?

Until OSE. We have reduced the distance between the drive gear even further

Advantages

- Simple design - Direct drive, meaning no gear-down that adds to complexity and long-term risk of wear. Limited machining is required. Anyone who has a 6 mm tap hole can build the full extruder from scratch.

- Open design - both in terms of Libre Hardware and easy-to-access filament path. The filament path from the filament entry aperture to the heat break aperture is completely visible. This means - by design - the filament path to the hot area is clog-proof. The tensioner can be removed with only one readily accessible screw. The fan is out of the way of the filament path - located below so that you can see exactly what is happening to the filament. This means literally zero down time due to extrusion problems. No more cursing as you disassemble the entire extruder with tiny parts flying out as 15 minutes of your precious life is sucked out of you for no good reason like in other leading brands (we won't mention names).

- Rubber-Optimized 3 mm extruder. Shortest distance in the industry between the drive gear and heat break out of all 3 mm extruders (25 mm for Universal Gearless vs 30 mm for Titan Aero, 55 mm for E3D v6, or 55 mm for J-Head). This means the highest-performing 3mm extruder for not only standard filaments - but also for flexible filaments.

- Optimized for both 1.75 mm and 3 mm filament. Use 1.75 mm without any change, and still get excellent results. To optimize for 1.75 mm, Just loosen 2 readily-accessible bolts to switch to a heat sink with the smaller heat break.

- Interoperatble with E3D Heater blocks - such as the Volcano and Supervolcano

- Ships stock with the Volcano heater block for printing faster than the more common E3D V6 heater blocks.

Disadvantages

- The more powerful 72 oz in stepper motor makes for a heavier weight than extruders with geardown and smaller stepper motors, requiring a solid and robust printer frame. This is an advantage for large printers (24" print bed and larger)

- As of version v20.05.02, a custom heat break would be useful to bring the heat break entry point 4 mm closer to the drive gear. We have not done this yet as we are still using stock (COTS) heat breaks

- We have yet to make this a machining-less design - a clamp-on threadless design - where instead of being threaded in, tubes are clamped on. J-Head does not currently use threads, just press fit. We want Design-for-Disassembly, so we do not use press fit.

Data

- side-by-side comparison to Titan Aero for max print rate with flexible materials - compare the fastest extrusion rates for rubber, using 1.2 mm nozzles, with and without retraction