CEB Press

- HABITAT: CEB Press - Sawmill - Living Machines - Modular Housing Units

- AGROECOLOGY: LifeTrac Multi Purpose Tractor - MicroTrac - Power Cube - Agricultural Spader - Agricultural Microcombine - Hammer Mill - Well Drilling Rig - Organoponic Raised Bed Gardening - Orchard and Nursery - Modular Greenhouse Units - Bakery - Dairy - Energy Food Bars - Freeze Dried Fruit Powders

- ENERGY: Pyrolysis Oil - Babington Burner - Solar Combined Heat Power System - Steam Engine Construction Set - Solar Turbine - Electric Motors/Generators - Inverters & Grid Intertie - Batteries

- FLEXIBLE INDUSTRY: Lathe - Torch Table - Multimachine & Flex Fab - Plastic Extrusion & Molding - Metal Casting and Extrusion

- TRANSPORT: Open Source Car

- MATERIALS: Bioplastics

Introduction

This page is an introduction to the collaborative development of a high performance CEB (Compressed Earth Block) press,The Liberator. We aim to provide a low-cost, ecological, ergonomical, and economically-significant press. The design process and final plans will be "Open Source"-- part of the public domain, with free access to anyone. The press is designed through voluntary efforts. Funding for parts, labor, testing, and development are procured via donations from interested parties (ie. builders, buyers, producers of CEB presses; community developers; general supporters of our work). At the same time, we are developing an open source enterprise, according to the principles of neocommercialization If you are interested in helping the development process in any way, please feel free to contact us.

As detailed in the outline above, below is an overview of the CEB, our work on The Liberator including timeline and budget goals, and resources. For more details, please also see our weblog which we update with CEB information frequently. This link will send you directly to CEB-relevant posts.

OSE Product Development Cycle - CEB Overview

The key to a low cost product is to utilize open source development and co-funding. The essence of the fundraising mechanism is that a large pool of stakeholders are invited to make small, voluntary contributions by using an online funding basket with PayPal (currently under development by collaborator Sam Rose). When a designated sum is collected, the project moves forward. When the sum is not collected, then none of the PayPal commitments are charged.

Potential stakeholders for "The Liberator" include those interested in:

- Buying a CEB press at a predicted cost of $3-5k (dependant on fabrication abilities), for a machine that produces 3-5 bricks per minute (ie. contractors, owner-builders, brick-producing enterpriser, natural builders, community developers)

- Building a CEB press (DIY or low-budget individuals, organizations, and companies)

- Starting an enterprise for producing CEB presses (distributed production reduces shipping costs and increases local control)

- Our overall goals at Open Source Ecology (appropriate technology development; sustainable and just living and livelihoods; localized production)

Our general strategy and organizational process for developing products, including the CEB is described here.

On this page, we go through the actual process, from concepts (see 2.2 eco-review) to design (2.4) to prototype to fabrication facility (2.4.3) to production for market.

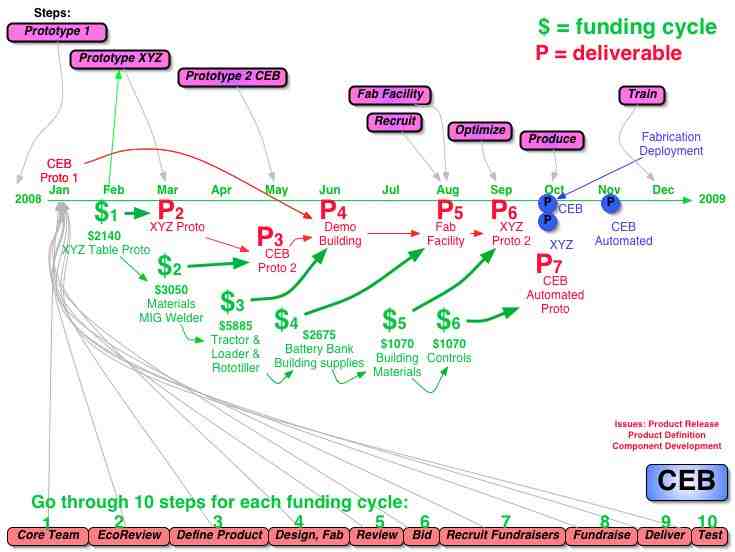

The timeline for 2008 is:

This timeline shows the development cycles on top, along with the corresponding funding cycles and deliverables in green and red. For each development cycle, we adapt a 10-step procedure, whose steps are shown at the bottom of the diagram.

In short, the development process cycles through two prototypes of the CEB machine itself, and two prototypes of an XYZ, computer controlled torch table (see professional version and open source version). The torch table will be used to automate the fabrication of the CEB machine, reducing fabrication time by an estimated 20 hours, and thus, also reducing the cost of the final product.

The development timeline also includes building actual structures to test the quality of the blocks and durability and ease of use of the press. Moreover, we will build a production facility for the CEB machines, and develop an open source business model to disseminate production of these machines to other areas of the world.

Step 1. Core Team

Technical Development: Factor e Team

Social Enterprise Development: Sam Rose

We are looking for peer reviewers, strategic developers, and a fundraising team.

Step 2. Ecological Review

last updated January 27, 2008

We ask a basic question at the outset: is the CEB press worth developing? Wikipedia provides a neutral overview of the CEB construction method. We do not have a neutral evaluation of this building technique because we conclude that no other building method comes close when an integrated evaluation is considered, especially in the USA.

Consider these main building options for North America. You have a choice of wood: stick-frame, timber frame, post and beam; structural masonry: brick, concrete block, rock, CEB (note that CEB falls into the class of structural masonry); earth-mix: adobe, rammed earth, stabilized earth blocks, cob, earthbag; and other natural building methods: strawbale, cordwood, papercrete, earthships and variations of all types. Here are some considerations.

Suitability of building technique for economic localization

A Compressed Earth Block Press has a three fold potential to influence local economies in a positive way: by creating a building medium, as part of a "CEB brickworks", and through local press manufacturing.

Our personal experience with earthbag and cordwood construction has demonstrated that natural building methods may be cheap, but they take time. (We estimated $400 and 400 people hours went into the walls and roof of a ~200 square foot room.) A commerical, pre-built 200 sq ft "deluxe shed" costs $4,400. Missouri minimum wage is $6.50, but if we gave the workers a nice $10/hour, the price is equivalent. (Another company quoted their shed at $4,009 and I found a two-year old aluminum one on craigslist for $1500, which was originally bought at $2500.)

Compressed Earth Blocks open the possibility for a building method that is both natural and easy to construct. What makes them unique from other natural building methods? Uniformity. Wayne Nelson of Habitat for Humanity in his piece entitled "Compressed Earth Blocks" says, "Uniformly sized building components can result in less waste, faster construction and the possibility of using other pre-made components or modular manufactured building elements." High uniformity gives CEB a competitive advantage over other natural building methods, allowing the CEB to influence local economies as a building medium.

A CEB press also can also enhance the local economy through a brickworks facitility. Bricks can be made competitively at a local scale. In "Compressed Earth Block Volume 1: Manual of Production" by CRA Terre, Vincent Rigassi (see D.10), CEB is pronounced as "one of those rare 'modern materials' which has sufficient production flexibiltiy to enable it to be integrated into both formal and informal sectors of activity, from 'cottage' industry to full-scale industrial plants" (pg 5). In other words, a Compressed Earth Block Press is just as likely to succeed as a localized enterprise as it would at a grander scale.

The third method of influence on a local economy is via CEB press manufacturing. The Liberator is designed to be built with simple tools and off-the-shelf parts. The design has minimum welds, using only bolts to secure the frame together. Since no specialized tools or advanced skill level is needed, a local machine shop or adventurous entrepreneur could easily manufacture it, contributing to regional employment and localized economics.

Ecological qualities

CEB exemplifies the meaning "locally-made". The required clay-sand subsoil is locally available nearly everywhere. Even the mortar is made from this mix with additional water. (See: Wikipedia) Humus-rich top-soil can be preserved for agriculture and the resulting hole may become a basement, root-cellar, pond or smoothed out to blend with the landscape. If onsite soil is insufficient (ie. not enough, or unbalanced), than near-by off-site soil or ammendments might be an appropriate option. Miles traveled: near Zero.

Compare this to the stick-frame house. According to "Gate-to-Gate Life-Cycle Inventory of Softwood Lumber Production" by Michael R. Milota, Cynthia D. West, and Ian D. Hartley, lumber travels 65 miles on average, just to get to the mill. Numerous unnatural materials are often used (ie vinyl siding and insulation) that have their own set of negative ecological consequences.

Other natural building methods have variably high scores on local, ecological use of materials, provided the materials are locally abundant.

The CEB does fall short of perfection in a couple respects. The press and other needed equipment (ie. rototiller and tractor) are not made from locally harvested materials. However, almost all building methods require use of some heavy machinery, and to its advantage, the press is designed to be locally manufactured. Also, The Liberator is not designed to make roofing shingles (although these can be made from compressed earth). So, the ecological qualities of the roof cannot be addressed.

Durability

A. Strength

Strength of CEBs depends on the machine (especially automated versus manual) and the quality of the soil (poorly mixed soil can lead to a weaker brick). According to Wikipedia, "CEB can have a compressive strength as high as 2,000 pounds per square inch. Blocks with compressive strengths of 1,200 to 1,400 p.s.i. are common." We have not yet strength-tested blocks from The Liberator".

The compressive strength of CEB sounds impressive, but according to Fred Webster, Ph.D. seismic Engineer in his paper "Some Thoughts on'Adobe Codes', it is neither the only nor the most important variable in determining the ability of CEB's to withstand loads. "In actuality, high compressive strength is and should not be the greatest concern related to pressed block quality. If the block has a compressive strength of 1000 psi rather than 300 psi, it is quite superfluous to the performance of the building subjected to ordinary service loads or even earthquake loads. It is not requisite that earthen blocks be up to the standard of concrete in order to perform well during severe earthquake shaking." Webster suggests that soil quality may be more important than compressive strength in determining the bricks overall durability. "Standards for appropriate soil selection need to be aggressively and rationally developed and tested by the pressed block industry. Currently, the best standards and research are being performed by BASIN, a combined appropriate technology effort made up of Germany, England, Switzerland, and France" (Webster).

B. Water Resistance

Although high quality blocks display water-resistant qualities, they are not waterproof and commercial builders, such as Midwest Earth Builders use a stucco to protect the exterior walls. Other design features, such as a large overhang can also provide some protection against weathering.

C. Fire and Mold-proof

Economics: The press, initial building cost, maintenance

A. The Press

The Liberator is a hydraulic powered press with an estimated output of 3-5 blocks per minute. A power source is required. See Specifications section below for more details.

Two comparable machines are available on the market today: Powell and Sons has one at 2-3 blocks per minute ~$10,400 (call for exact pricing) AECT has a 3-5 block per minute version at ~$25,000. Again call for exact pricing. Numerous "slow-speed" machines can be found at various price ranges.

Each has slightly different features and advantages and both of the above machines come with a power source. However, we believe including a power source is superfluous, as most people or companies who work with a high-speed machine, will also have access to a tractor or other source of hydraulic power. Those who do not, will have to invest in a seperate motor. We believe that when possible one motor should do the work of many machines. This reduces the number of machines and parts that require maintenance.

Parts for The Liberator as detailed below, are approximately $1000. The machine will cost an estimated $3-5K, depending on manufacturing abilities.

A tractor with loader and rototiller are required to prepare the soil. These are additional costs. Other equipment and their related costs are detailed in the pdf CEB manual D.10 found on the BASIN website.

B. Building Costs

CEB press maker AECT claims, "the cost of the structural compressed earth block construction using the AECT structural compressed earth block machines to produce the structural masonry blocks is between 25-40% less expensive than the next closest construction approach for quality, long lasting and energy efficient structures. Some other cheaper construction techniques are inexpensive, but the resulting housing or commercial buildings are cheap, structurally deficient, noisy, and wasteful in energy use and not appealing to homeowners or commercial tenants."

But when compared strictly on economic terms to a conventional home, natural building methods save surprisingly little. Most natural building methods use convential roofs and foundations. Only the walls are constructed from alternative materials.

From their experience, Midwest Earth Builders (MEB) claim "Because CEBs are used entirely as a wall system, the remaining costs, which can represent 80-90% of the total cost of the home, will be the same as conventional building. For example, the cost of the roof, windows, cabinets, etc. are the same for a framed and CEB home.

Building the wall of a home typically represents 10-20% of the total cost of a home. A CEB wall will average 15% more then a conventionally built wall. In other words if the wall of a conventional home cost $15,000 for a $100,000 home, it will cost $2,250 more for a CEB wall."

A similar summary of straw bale housing is given from Green Home Building. "Erecting bale walls can go amazingly quickly, and does not take a lot of skill, but then the rest of the creation of the building is similar to any other wood framed house. In fact strawbale houses typically only save about 15% of the wood used in a conventionally framed house. The cost of finishing a strawbale house can often exceed that of standard construction, because of the specialized work that goes into plastering both sides of the walls. The result is often worth it though, because of the superior insulation and wall depth that is achieved."

Many claim that the qualities unique to natural homes (especially heating and cooling properties) more than makes up for the initial cost difference. This may be true for one who can afford the added up-front expense. But what about the rest of the world? Is CEB a technique that is affordable to the average American or even the urban or rural poor of the "Majority Countries" (Also referred to as developing, third world, or underdeveloped countries)?

Since Habitat for Humanity, among other development-working agencies (see [BASIN partners) use CEBs for home building, the obvious answer is yes. Just as stick-frame homes can be made cheaply (ie. mobile homes), so can CEB structures. Except, the quality of "cheap" CEB homes will far out-way the quality of mobiles.

Other points to consider:

- Can the technique be learned quickly by unskilled labor or are paid, skilled professionals needed to do the work? As we saw above, stuccoing straw bale buildings may be better left to a professional. CEB requires little skill and is therefore, a good forthe owner-builder. While normal masonary work requires skilled professionals to apply a thick (1/4-1/2") layer of motor between layers of bricks, "[b]ecause earth blocks do not require thick mortar joints, walls can be built quickly by workers unskilled in masonry" (MEB). Furthermore MEB claims, "[c]ost on a per block basis average approximately $1.10 per block. A 1000 square foot home will need approximately 5,500 blocks. So, $6,050 would be the block costs. Once again, we have worked with customers who have provided their own labor and tractor for loading, and have brought this cost down to $.50 to $.60/block." Please note, that somewhere in this figure is the price of the use of their machine, which they got from Powell and Sons.

- Can other parts of the building be made more economically? CEB can be made into roofing shingles with a roof-tile mold D.10. Conventional roofs are easily held by CEB: "If the block has a compressive strength of 1000 psi rather than 300 psi, it is quite superfluous to the performance of the building subjected to ordinary service loads or even earthquake loads" (Webster). Thus, it seems safe to assume that a CEB wall, appropriately constructed, could hold up the weight of a living roof. Although again, with current technologies, it is more expensive up-front, with long-term savings in maintenance and heating.

- Because CEB is an on-site material and because all parts of the process can be done by hand or machine, it lends itself to great variability of final product prices. Habitat for Humanity uses CEB in some of their projects. And BASIN is comprised of organizations which do development work. So, obviously, CEB homes do NOT need to cost as much as conventionally-built ones.

C. Maintenance Costs

The Liberator was designed with reduced maintenance in mind. Durability testing has not taken place yet, but the main part that may need replacement is a rubber sheet from McMaster-Carr. The press is Designed for Disassembly (DfD), so if repairs are needed, the cost should be minimal.

CEB buildings may need to be re-finished (stucco) coating, just like a house would need new paint. If a conventional roof is used, maintenance repairs would be identical to a traditional house. More research is needed on maintenance costs of a CEB building.

Furthermore, CEB can be used in other applications besides housing.

Building ergonomics

3-5 bricks per minute (bricks are 6x12x4 inches) means enough blocks for a 6 foot high wall for a 300 square foot round building can made in one workday.

The ease of the entire process will depend on

- Set-up (Is the workspace well arranged?)

- Equipment (Tractor, front end loader, rototiller, mixer, etc... will make the work easier and faster, assuming no breakdowns. Less tools will require more manual labor, which may or may not be appropriate depending on the situation.)

- Soil quality (If the mixing ingredients are friable and at a good moisture content, the process will be easier and faster.)

Once the blocks are made, high-quality blocks without stablizers can be layed directly. Low-compression and stabalized blocks should be set to cure for varying amounts of time.

The bigger the block size, the faster a wall is errected. And obviously, the bigger the block size, the heavier the block. Blocks from The Liberator will average 25 pounds.

Even if the workers are unskilled, building with CEB can be relatively quick. MEB explains, "One does not have to be an experienced mason to build with CEBs. Homeowners, contractors, and builders can quickly be taught how to stack a wall and begin construction immediately. Because only a thin mortar/slurry joint is used between blocks, walls go up quickly and there is no need to wait for the mortar to set up after a few rows like with typical brick masonry."

Our experience with Cordwood and Earthbag building did not mimic the experience described here of building with CEB. Although these natural building techniques are also learned quickly by the novice, actual construction time and ease of construction seem more difficult. Earthbag construction requires filling, stacking and tamping bags of earth. As the walls get higher, the bags must be lifted accordingly. Barbed wire is strung between layers of bags. The process is not easily mechanized. And the walls require stuccoing afterwords. Cordwood was also difficult. Wood has to be cut, stacked, restacked and stacked again. We were surprised at how much wood was required for a small addition. Furthermore, both cordwood and earthbags have the distinct disadvantage of being irregular.

Thermal properties

Have you heard of Thermal Flywheel? CEB exemplifies this property as heat and cool is stored and released from the walls. Summer is cooler (as we have already experienced in our earthbag room with the same property) and winter is warmer. However, thermal flywheel is different than insulation. The heat you generate from the stove in winter is stored in the walls, but is eventually released back into the cold outside. A double layer of bricks with an insulative infill can resolve this effect. In colder climates this is wise. In warmer climates it is unnecessary.

Insulation can be standard styrofoam or an unconventional sawdust/lime mixutre or perlite. Other materials should be experiemented with.

Aesthetics

MEB photo gallery CebTex CebTex2 exterior images AECT interior images AECT Midland Project Construction Pictures by Earthblock Texas Homes

Stick frame construction is the main building method in North America. It is a weak but fast building method, which makes money for developers but returns little value to the homeowner, if one considers lifecycle cost of buildings. (note the lifecycle use of materials in Greenforms at CMPBS) Procuring lumber drains money out of local economies. This is not to mention clear-cutting and vast lumber monocultures that supply the lumber. We are interested in raising the standard of building, away from stick frame. We believe that with all these considerations, the CEB is the only building technique that even remotely has a chance of substituting for stick frame constuction, and that with our machine, priced $3-5k and designed for fabrication replication, will fill in a great need. CEB construction has the potential for mainstreamability in home construction.

We have heard one recurring critique of CEB construction. It has been said that CEB building is either for the idle rich, who can afford the high cost of construction, or the idle poor, who can afford to take the time to build the house. Both cases imply outrageous time requirements, and this appears inconsistent with claim 5 above. Based on our experience we find that to be untrue. We believe that the truth is that poor people do not have access to high performance machines, and rich people are charged a lot because the quality of the finished product is high, regardless of how many hours went into construction. The answer to this seeming inconsistency is the availability of a high-performance, low-cost Liberator.

Our experience has shown $30/square foot costs for the cordwood house, and similar rates for the earthbag house, if $10/hour labor is considered. We estimate time requirements to be at least 5 times shorter for CEB construction, we are expecting $5/sq ft total building costs including $10/hour labor. That is dirt cheap for top quality housing. Direct data, gathered from our building program beginning in April, will prove or disprove our claims.

For these reasons, we conclude that anyone who is interested in building a new house, or making a house addition, should consider the CEB press seriously because of its ecological, economic, durability, replicability, and localization merits. While other building techniques may be superior on one of these qualities, CEB construction is the only technique that scores well on all these criteria.

Step 3. Product Definition

Deliverable

Here are the specifications for the OSE CEB machine: The Liberator. Lifetime specifications will be verified in field testing.

- Bricks per minute output: 3-5

- Brick size: 12x6x6 inches (30.5x15.3x10.2 cm)

- People operating machine: 1-2

- Machine power source: tractor hydraulics or any hydraulic power source with 6 gallon per minute capacity

- Machine mounting: tractor 3 point hitch or stand-alone foot

- Hydraulic pressure: 2000psi

- Hydraulic cylinder: 5 inch diameter, 19.6 inch area; 2.5 inch rod

- Pressing cylinder pressure: 39,250 lb pushing force (~18 tons)

- Controls: 2 spool, manual, hydraulic valve; automatic version forthcoming.

- Compressive strength of bricks: to be measured

- Structural cold rolled steel construction throughout

- Design-for disassembly: full bolt-together construction for frame, compression chamber, table, tractor mount, and feet; welded hopper assembly and press plate; cylinders readily removable with pins

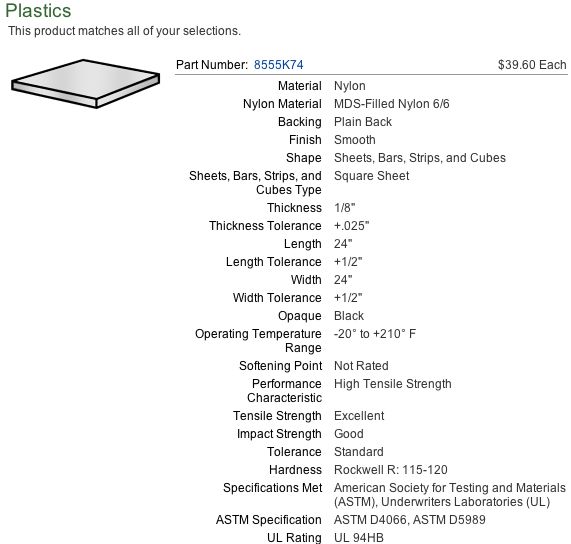

- Wearable components: 1/8" Nylon 6/6 liner on compression chamber and table surface, each piece held by 2 bolts

- Machine lifetime goals: 1 million bricks before repairs; liner may be replaced every 100,000 bricks

- Material costs: $1000-1350

- Fabrication time requirement for optimized production: 3-5 days, about 20 hours of direct fabrication

- Manual fabrication tooling requirements: drill press, welder, acetylene torch

- Optimal fabrication tooling: XYZ table with torch, MIG welder, hoist

- Cost for machine: $3-5k

Future phases for CEB evolution that we are considering beyond the present funding cycle are:

- Fully automated CEB machine, like The Liberator, where manual controls are replaced with automoatic valves and a control circuit. The only control required is turning the machine on, and from that point one simply loads soil and unloads bricks. Added material costs in this version are approximately $500.

- More powerful machines. More speed may be achieved by

- A dual machine, which features 2 compression chambers operating in parallel

- Faster machine by virtue of redesign to allow faster cycling through the steps

The automated machine is a clear and desirable upgrade, which essentially frees up one person to load soil, unload bricks, and build with the bricks right after they are produced. The other machines, such as dual or faster versions, will be reevaluated after significant experience has been reached by the Factor e Team and collaborators.

We would like to emphasize our approach and cost predictions: we're open source, lean, mean, and optimal. This effort is funded by voluntary contributions, so our development costs are zero. We have low overhead costs of $107 per person per month because we have donated facilities and lifetime tenure. We are working on a thorough process for a quality product. Indeed, we aim to create a new model for the way products are developed. We aim for full transparency in our development process, so you can see how your money is being spent. And, we are giving the business model away for others to replicate. No strings attached. You can read details of our 3-year plan here.

Our pricing policy is to cover labor and fabrication costs, and to capture value from optimized fabrication. This means that both sides win: we are able to fund further developments by putting all proceeds back into the operation, and you get a low-cost product. We are able to consider special payment arrangements for collaborators or others interested in development for the common good. We do not want cost to stand in the way of access to liberatory technology.

Budget

Bill of Materials

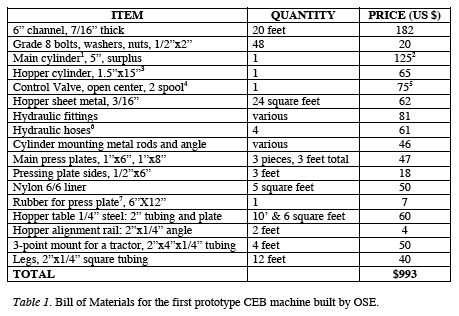

Here we present an economic analysis for the CEB machine to explain costs involved.

Here is the Bill of Materials (BOM) for the CEB prototype:

References:

- https://www.surpluscenter.com/item.asp?UID=2008010512293756&item=9-1143-08&catname=hydraulic

- Gotten from surplus.

- https://www.surpluscenter.com/item.asp?UID=2008010512293756&item=9-7156&catname=hydraulic

- https://www.surpluscenter.com/item.asp?UID=2008010512293756&item=9-6702&catname=hydraulic for $156

- Gotten from surplus.

- Item # 905-12120 and 905-1236 at https://www.surpluscenter.com/

- Item 8609K13 at http://www.mcmaster.com/

The main cylinder and control valve used were from surplus, so this price may rise by about $250 for the cylinder and $100 for the valve, for a total of about $1350 in readily-accessible parts. The total number of hours spent building this protoptype was about 140 hours. The time expected for fabricating the second prototype is 40 hours. Production runs are expected to take about 20 hours per machine, using an XYZ torch table for fabrication assist.

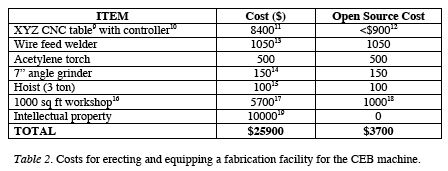

Fabrication Facility

Here are the capitalization requirements for fabrication capacity. The Cost column reflects the price structure if off-the-shelf tools and materials - and proprietary development procedures - are utilized. This cost is conservative, as intellectual property costs are probably higher than the $10k that was specified. The alternative route, or the Open Source Cost, is that which utilizes open source know-how and is built on a land-based facility. The open source option means that certain equipment may be fabricated readily from available components when a design and bill of materials is available.

References: 9. www.torchmate.com ; 10. Does not include the control computer; 11. Torchmate 3, http://www.torchmate.com/overview/index2.htm ; 12. http://bluumax.com/ ; 13. http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43550 ; 14. http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_200306001_200306001 ; 15. http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_18544_18544 ; 16. Not including land costs; 17. Cheapest barn kit: http://diypolebarns.com/pb_kits.php , more expensive: http://www.shelter-kit.com/b_prices.html ; 18. Using CEB construction with on-site soils, plus site-milled lumber leaves only doors, windows, foundation, and electrical costs of building; 19. This is difficult to estimate, but here we will include 200 hours of development work at $50 per hour- for producing 2 prototypes and testing prior to production runs.

In particular, the great cost reducer in the open source route is the availability of: (1) a low-cost XYZ table, (2), low cost workshop building, and (3), absence of intellectual property costs. In total, the price of putting together a fabrication facility is only $3700 if one has access to land, some kind of tractor or skid loader for material handling, and utilizes onsite building materials (CEBs and milled lumber) to construct the workshop space. It should be added that more labor will go into building an XYZ table than buying one, but not much more, if a transparent bill of materials and fabrication procedure is available. Workshop building time may also increase over the off-shelf option.

The XY table is a pricey solution if obtained off-the-shelf. New kits cost $8k at the low end for an industrial duty, 4x8 foot table. We should note that, as expected from the open source development method, ridiculously low costs are feasible for the CNC table. For example, a small CNC mill is under $200. The electronics of a CNC XY table are inexpensive. Three stepper motors plus controller and power supply cost $45. (http://bluumax.com/ - Note - these stepper motors are half the required size, so we expect the real price to scale accordingly.) Rails may be the expensive part, and other than that, it’s mostly a structure that can be fabricated via xyz bolt-together design. The CNC table should be accessible at <$500 plus structural steel at approximately $400. That is a Factor 10 reduction over the competition.

The cost structure for building a physical production facility for the CEB will be documented fully with forthcoming experience in 2008. We will be building this facility at Factor E Farm. Part of the development will be deploying an open source XYZ table, which we expect to cost <$900 in parts. There may be additional costs involved in finalizing a simple design for the XYZ table. The goal is a facility that can produce 1 CEB machine every 3 days with 1 fabricator working full time.

We will set up a social enterprise website to raise between $3700-5000 for deploying CEB machine fabrication. This site will designed to motivate the minimal funding of the facility, by directing as many potential stakeholders to the site as possible. Stakeholders include owner-builders interested in natural building, building organizations such as Habitat for Humanity, disaster relief organizations, building contractors, and a wide range of others. We are asking for collaboration in directing potential stakeholders to the funding website.

In summary, this is our first experiment of co-funding a significant production facility. Deployment funds will be used to build the facility, procure some tools, and build an open source version of the XYZ table. Utilizing existing collaboration, we will use up to $3k from the budget to design, build, and deploy the XYZ table. Together with Factor e Farm contribution of facility space, a fabricator who has already been recruited, and utilization of onsite materials for facility construction – we believe that we have an attractive package that can be funded. Costs and risk are distributed, and low overhead makes the entire project dirt cheap for the significance of the promised deliverable. It is a pressing issue (no pun intended) for us to deploy CEB machine production with 3-5 day delivery time – for proving a novel, state-of-art peer production mechanism.

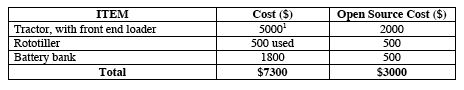

Heavy Equipment

The balance of the budget for the open source CEB development is in materials handling and testing: a tractor with front end loader and rototiller. The tractor is required for soil preparation: digging soil and rototilling the soil to prepare it for use in the CEB machine. The tractor is also used to power the CEB machine for testing, and for material handling of raw steel that is used in the CEB machine. Moreover, we are presently utilizing a tractor to generate 20 kW of electricity by using a power take-off (PTO) generator. This powers the welder and other equipment, but we aim to replace this with a renewable power system as soon as we can. We currently run smaller electrical tools with a 3 kW inverter and a battery bank. These costs summarized are:

Notes: 1. We are considering an Allis Chalmers D17 Series IV Diesel tractor as a robust, all purpose tractor with good hydraulics

Timeline

The goals are to produce a hydraulically-driven, manually operated CEB press ready for sale by October, 2008. By November, we aim to produce a fully automated hydraulic machine. By December, we aim to develop a training program for builders of the CEB machine.

Given the budget explanations above, here are the funding cycles that we are proposing for this project. Delivery date for optimized production is November 1, 2008, when we will begin filling orders.

The funding cycle overview is:

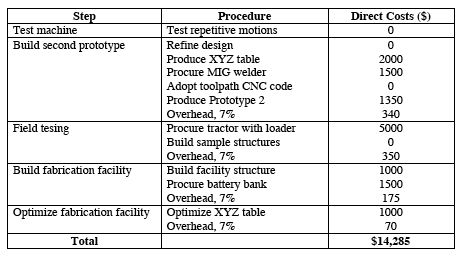

The table above shows the deployment costs with 7% overhead for fiduciary duties of funding collection management. The cycles in detail are:

The first funding cycle starts Feb 1, and continues for 4 weeks. We hope to collect the necessary funding via a concerted 2 week effort with our volunteer fundraising team. The funding cycle carries on for 4 weeks, but the actual developments with the proceeds collected last longer.

Cycle 1: Feb. 1 – Feb. 28 Collection Cycle, $5190 - XYZ table, and 2nd Prototype

- Recruiting core team

- Recruiting reviewers

- Documenting all past design and fabrication work

- Distributing present effort out for review

- Designing XYZ table by Feb. 1

- Reviewing XYZ table by Feb. 7

- Procuring fabrication bids for table by Feb. 14

- Fabricating XYZ table, by Mar. 8

- Procuring MIG welder by Mar. 8

- Producing prototype 2 by Mar. 31

Cycle 2: March 1-March 31 Collection Cycle, $5350 - Demo Buildings

- Procure tractor with front-end loader by April 7

- We will build our first significant demonstration structures with the 2 CEB prototypes. Construction will continue for 1 month to document experience with the ergonomics and economics of this method, and to verify field performance of the 2 CEB prototypes.

Cycle 3: April 1-April 30 Collection Cycle, $2675 - Fabrication Facility

- Note: this covers the foundation, doors, water, and electrical hookup, as well as extra battery power to run the facility.

- Procure battery bank

- Build facility for fabricating CEB machines

Cycle 4: May 1-May 30 Collection Cycle, $3210 - Optimize Production for Replicability

- Production facility optimization

- Produce replicable design for XYZ table

- Build second XYZ table prototype to prove the economics of fabrication of the XYZ table

- Make any rearrangements in fabrication facility to facilitate workfow

- Build additional accommodations for additional fabricators. We are planning on 4 new fabricator positions.

Step 4. Design and Fabrication

We have already built a prototype, which we discussed at our blog here. We posted the fabrication procedure pictures - CEB_Prototype_1_Fab. The design evolution for the prototype is documented at Worknets. The relevant technical drawings that we have to date are here. These drawings are not complete, so please contact us if you can help us with the drawings.

Design has 5 major components:

- Documentation of CEB Prototype 1 (shown above)

- XYZ table for automating fabrication - present work, Jan-Feb 2008

- Documentation of CEB Prototype 2

- Facility Design

- Final CEB design

At this point, we move into CEB Funding Cycle 1 to deliver the XYZ Torch Table for producing the CEB machine more effectively.

Reviews

We welcome reviews of all the above content and concepts by stakeholders and interested individuals. Please send comments to joseph.dolittle@gmail.com.

Technical Reviews

Social Enterprise Reviews

- Review of the social enterprise experiment by P2P Foundation

- Review by Samuel Rose of Social Synergy

- P2P Foundation review of the economic model

Strategic Review

Economic Review

CEB may be set for a second renaissance. Cheap energy has put the emphasis on cement based construction for many decades. Scarcity driven by peak oil and political instability will combine to make low energy construction methods more attractive.

The biggest need is for a low energy stabilization method. While there are examples of buildings that have survive for many centuries, many required considerable maintenance. Others have decayed rapidly in modern times without constant recoating. One development that may make a huge difference for CEB's is enzyme stabilization. Products such as Permazyme 11X, EcoBric and others may make possible the low energy manufacture of bricks and blocks that have weather resistance approaching concrete. The enzyme products are nontoxice and relatively low cost. $40-$60 worth of Permazyme is supposed to stabilize enough earth for a large house.(Permazyme@$120/gal. stabilizes 150 cu yds) I have been unable to find any builders using these products for CEB(though EcoBric is aimed at that market) but there seems to be considerable experience stabilizing road bases. The manufacturers have concentrated on the road building market because of the money. After all, 1 or 2 liters for a house isn't much compared to 15 gallons per mile of road. The original patents seem to have expired, so it may be possible to come up with an open source recipe for the enzyme. It may not be an enzyme at all. The first product of this type came about when a vintner notice the the waste from wine-making hardened the soil where it was dumped.

An inexpensive low energy way to stabilze compressed earth combined with low cost mechanization could make CEB's a significant contributor to an ecological housing solution for the future.

Replicability and Transformative Potential Review

Further Resources

Our program is unique in that we are producing both an open source product, and also developing an open source model for the enterprise itself. You may read a review of this novel organizational model at the P2P Foundation website by clicking here.

A good article on the CEB may be found at Wikipedia, Compresssed Earth Block. There are several good online books: click Earth at the left hand bar on this website.

- AECT - CEB press fabricator - [pages.sbcglobal.net/fwehman/]

- Powell and Sons - CEB press fabricator - [1]

- Gernot Minke - one of the world's leaders in earth construction - see [2] for thorough overview, including detailed soil testing procedures.

- Galvanized wire reinforced, earthquake resistant earth construction techniques publication - [3]

- Ronald Rael is an Architect, Author and Assistant Professor of Architecture at The University of California, Berkeley. He is the founder of EarthArchitecture.org, a clearing house of information on the subject. May be interested in our work.

- Compressed Earth Block Guide - [4]

- CEB, Manual of Production - [5]

- What can happen in earthquakes - [8] , [9] , [10]

- Other information - [11] , [12]

How about through-tie with rebar? We are considering this for double brick thickness walls. We could use technical help on this.

- Rebar can get very expensive in the developing world. The galvinized wire reinforcing is much lighter, (aka a shipping container from these guys as an examle - [13] , **probably could provide better resistance to earthquake, simular pricing to rebar per pound, and probably 5 times the support per pound of material) as well as not needing double thickness which cuts down on labor.

Bill of Materials

- Wear-resistant liner - MDS-Filled Nylon 6/6 from McMaster Carr

Public Responses

The following is a letter I recieved in response to a Countryside Magazine article (July/August 2008, pg 40) which discusses our building experiences at Factor E Farm. This reader has back-of-the-envelope plans for a manual CEB press. Manual presses are useful in places when labor is more accessible/cheaper than equipment. This letter also shows the general simplicity of the CEB-- the task at hand, compressing soil into bricks-- is not that complicated.