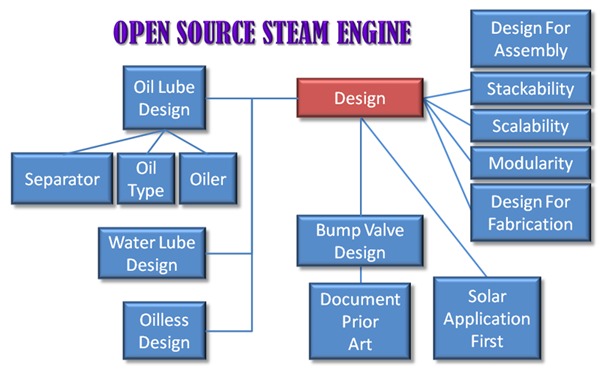

Steam Engine Design

Jump to navigation

Jump to search

Main > Energy > Steam Engine

This page will be used to describe the OSE Open Source Steam Engine design, design issues, and completed drawings.

See bump valve prior art - http://www.rossen.ch/solar/wcengine.html

See also:

- Existing and Historic Designs

- Other Engine Designs

- Steam Generator Designs

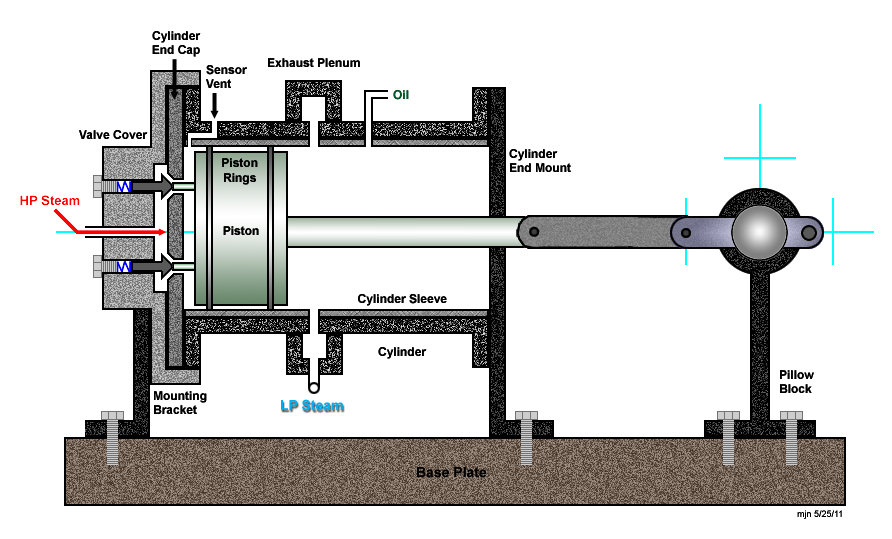

Bump Valve Engine Design

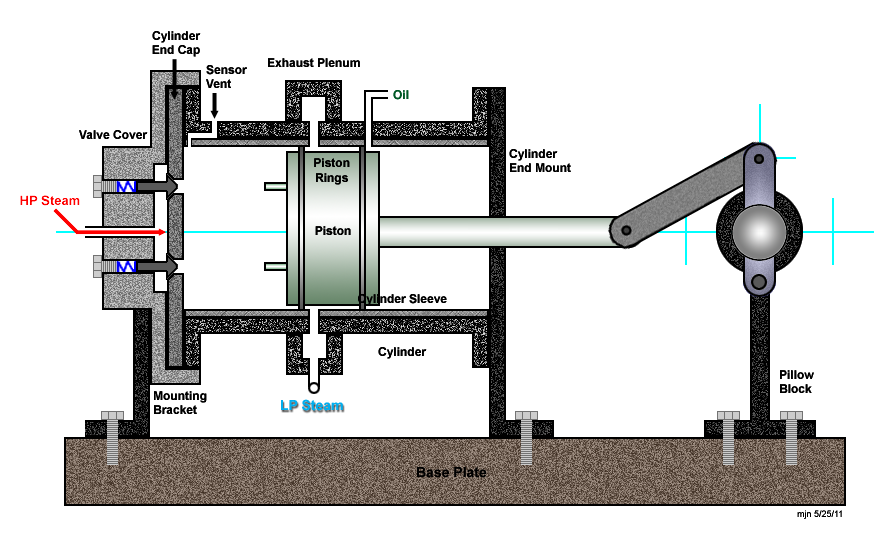

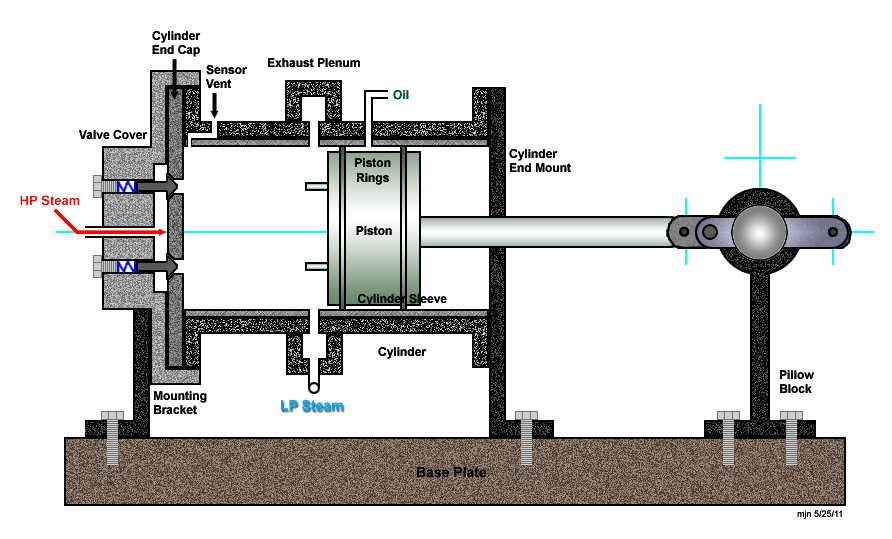

Three points in the steam cycle are shown.

Design Updates:

- 5/2/11 - Rev. 2: Initial bump valve design.

- 5/6/11 - Rev. 3: Added flange on crankshaft end of cylinder and exhaust plenum.

- 5/10/11 - Rev. 4: Improved bump valve added, cylinder liner is now thick.

- 5/11/11 - Rev. 5: Added mount brackets, pillow block, extended piston stem.

- 5/25/11 - Rev. 6: Widened cylinder flanges, dropped water vent, added sensor vent, cylinder liner to scale.

1. Steam Fires

2. Steam Expands

3. Steam Vents

Description

This is a single-action uniflow steam engine that uses a bump valve to admit steam and an exhaust vent to emit cooled steam.

Design Features:

- Simple design with a mix of fabricated and off-the-shelf parts.

- Modular and stackable - cylinders can be ganged together to increase power.

- Easy assembly - minimal welding

- Repairable - comes apart for cleaning, maintenance, and repair.

- Easy fabrication - lathing, milling, cutting, and drilling.

- Self-lubricating - oil sprays.

- Crank shaft can be configured for multiple cylinders.

Sub-assembly Designs:

- Steam Engine Design/Bump Valve

- Steam Engine Design/Cylinder

- Steam Engine Design/Crank Shaft

- Steam Engine Design/Piston

- Steam Engine Design/Lubrication

- Steam Engine Design/Exhaust

Alternative Designs:

Review Notes

Tom Kimmel of SACA

Some observations and recommendations from Tom:

- Do more research.

- Come to my shop and look at real steam engines.

- Add teeth to the flywheel to allow an electric starter motor.

- Cylinder liners (sleeve) should be cast iron. Look into motor rebuild kits.

- Valves are not "chinese hat". Talk to Jay Carr about his design.

- Open or closed crank is a choice. Not critical.

- Lubrication is important, but had no specific recommendations.

- Start with conservative materials (like iron) and consider advanced materials later (like nitride coatings).

- Consider designing an exhaust manifold from the start.

- Visit Bill Ryan north of Chicago who has experience with making bash valves.

- Don't use stainless steel as a cylinder line.

- Consider 12v electric system for fans, solenoids, relays, water level sensors, and starter motor.

Ken Helmick of SACA

Some observations and recommendations from Ken:

- Initial decisions having huge influence on final design.

- Higher operating pressures and temperatures lead to potentially higher efficiency.

- A uniflow engine has the potential of higher efficiency.

- A counterflow engine has the relative advantage of being more easily operated.

- Wrapping a sleeve and welding is not likely to yield a satisfactory engine

- To make a sleeve, consider:

- Cast it using a sand mold.

- Use off-the-shelf sleeves.

- Purchase already honed hydraulic cylinder tubes.

- Convert an existing IC engine or extensively utilize IC engine components.

- If welding is employed, stress-relieve the assembly and then re-hone lightly in case of any slight thermal induced distortion to the bore.

- Valve springs must be wound from superalloys and heat treated. Conventional springs will fail from the heat of the steam.

- Bump valve engines probably are more efficient at some moderate rpm.

- An alternative to bump valves is a smaller piston valve mounted coaxially with, and upon, the engine piston.

- Always enclose the crankcase of any higher rpm engine.

- There is an incredible variety of piston rings available in almost any size, configuration and material imaginable and this is about the last reason I would select a given engine diameter.

- Electric starter motors are simple. Older General Motors alternators are widely available and they have an integral voltage regulator.

- A uniflow exhaust manifold could be very, very simple, depending on the cylinder.

- The crankshaft is the heart of the engine.

- The average home machinist is typically not equipped for (nor capable of) building a multiple throw, one piece crankshaft.

- One route to consider is the built-up crank.

- If a one piece crank is desired, the best route to go would be to either cast a rough out of a high grade of iron.

- The home machinist can balance a crank with a single throw but multiple pin cranks can only be balanced in a shop with a dynamic balancing machine.