OSE Christmas Gift to the World 2012

See also OSE Christmas Gift to the World 2011

Introduction

Every year OSE provides a Christmas gift - to the entire world. This year, we have optimized production of the brick press signigicantly. We went from months in our first production run 4 years ago - to 4 days in September 2012, to 2 days in November - and we look forward to December 18, 2012 - as we build The Liberator - our open source, automated Compressed Earth Brick Press - in a single day.

A Single Day Production Run of the Brick Press is OSE's Christmas Gift to the World for 2012. This will be accompanied by full documentation - and readiness to see hundreds of these machines be used in 2013 around the world to build high quality housing at about half the cost of conventional building in the USA, and at 1/5th or less the cost for owner-builder construction.

A single day of production means that the builder can generate significant revenue from building and selling these brick presses. We intend production of The Liberator - and other Global Village Construction Set tools - to become a self-funding model for other open source projects. If you are an open source project according to the Open Source Hardware Association Open Source Hardware Definition, we invite you to contact us regarding strategic partnerships for working together - to create the Open Source Economy.

Process

For the first time, we will be relying on a CNC Torch Table to build The Liberator. Most of the subsequent tasks will be welding. We will use a manually assembled board or CNC circuit milled board as the core of the solenoid driver, with an Arduino controller. See The_Liberator#Electronics_-_CEB_Press_IV

Strategy

Radical Collaboration Strategy

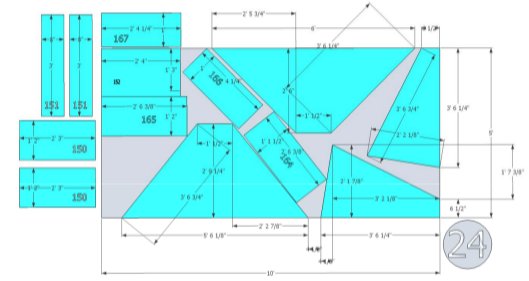

Redesign for CNC Torch Table

We begin by breaking the machine into parts, with Project Leader for each.

CEB Frame

The CEB frame can be fabricated completely from a single sheet of 1/2" mild steel if the frame is considered to be a weldment. U-channel can be welded from flats Because the frame is bolted together - the major part of frame fabrication involves measuring and drilling/punching holes. If the entire cut is done on a torch table, all the holes are guaranteed to align - and the frame fabrication process is reduced to welding and assembly. This is more ergonomic than using u-channel from the fabrication time perspective. It takes approximately 8 hours to build the frame and fit the cylinder if u-channel is used. This can be reduced to about 1 hour with parts cut on a CNC torch table.

CEB Drawer

CEB Grate

Hopper and 1/8" Steel Sheet Cutting

- Download pictures of modified fabrication drawings of CEB hopper, based on learnings from last production run: File:CEBfabmods.tar.gz*This is primarily the hopper, plus all guard shields.

- Hopper needs to have hole locations corrected.

- Hopper Work Statement - communicated to Chuck H.

Shaker

Supports & Tubing

The only parts not cut on the CNC torch table are supporting tubes and holders:

- Hopper supports

- Legs

- leg and support holders

- Cam roller holders

Arms & Legs

Cylinder

Hydraulics

The hydraulics include the main and secondary cylinders, shaker motor, pressure switch, solenoid valve, fittings, and hoses. The main assemblies, all connected with quick-coupled hoses, are:

- Shaker motor assembly

- Solenoid Valve Assembly

- Primary Cylinder Assembly

- Secondary Cylinder Assembly

- Hydraulic Pressure Switch - is required for bypass under nonuniform soil conditions

Electronics

Fabrication, Documentation, and Distributive Enterprise

We are looking for other teams to help on the overall Brick Press release.

CNC Torch Table + CAM File Development

CNC Mill

Documentation

Video

Ergonomics

Business Development

Event Information

General Information:

- Run is happening from 8AM - 8PM on Tuesday, December 18, 2012. Orientation/preparation day on the 17th.

- Maysville, Missouri location - travel to Kansas City International airport, 1 hour away.

- Stay in a nearby hotel in Cameron, Missouri - 15 miles away

- Free admission to True Fans, Bioneers East Conference participants, and Special Guests.

- $300 admission for interested fabricators in training and anyone interested in helping on the production run

- Expected number of people: 12-16

- Intensive learning experience

General Requirements:

- Liability Release waiver signed

- While fabrication or machining work is not required - some form of common-sense, hands-on experience, or familiarity of tools in productive work is essential. This could be experience building things, agriculture, construction, trades, etc.

- Bring steel toed shoes, work or welding gloves, and protective eyewear

- Individuals who are interested in participating in production are required to take an orientation, safety, and basic tool operation crash course - unless they are experienced welders. Welding and grinding will be the center of this training. The crash course will take place from 4-6 PM on December 17. *Workshop preparations, cleanup, and materials layout will happen from 1-4 PM pm on December 17.

Radical Collaboration

In this event, we will push the limits of open source, global collaboration. We are redesigning the machine for fabrication largely via the CNC Torch Table. This means that the machine CAM files can be modeled/tested on a CNC router or laser cutter. This allows for remote participation in development.

- Modeling - we are generating CNC files from Dec. 1-5. December 6-10, we would like to model the build. Anyone with a laser cutter or CNC router is invited to participate - by taking the CNC files and generating a fractional-scale model of the machine. This will test that everything fits together as it should. Email me at opensourceecology at gmail dot com if you would like to be involved in this.

- Cutting - after feedback is received from modelers, we will correct our CNC files and move forward to real metal cutting via CNC Torch Table. This can be done remotely - as our CNC Torch Table is not ready yet. The metal can be shipped to us for about $300 from anywhere in the USA.

- Fabrication Diagram - can you help us generate a Fabrication Diagram for the build?

- Documentation - can you help us on the wiki documentation on the CEB Press?

- Publishing - do you have a publishing platform that can be used to offer our Brick Press User Guide - as a chapter of the next iteration of the Civilization Starter Kit? We will offer downloads for free, and printed copies for sale. We are working with Paperight on this already, and we welcome others worldwide.

- Translation - help us translate - the wiki documentation, video subtitles - and especially the published copy - so we can publish the The Liberator Chapter of the Civilization Starter Kit in 100 languages.

- Remote Video Editing - We will aim to upload 1GB of footage to our Vimeo Account the day of the production run - and we request remote video editors to contact us to generate a video from the production run. We will share our video assets - title page, ending page - and you can run with the rest. Room for creativity.

- T-Shirts - those participating in the build surely don't want to go home without the December 18 Production Run T-Shirt? Who can design one and get it printed?

- The Liberator stickers - surely if we want hundreds of these machines to be built in 2013, a nice sticker would help? Who can design one and add it to our swag store offerings?

- Tooling Development - The Millermatic 200 welder is an old-school gem, and is hard to find. It is one of those long-life welders from the 1980s that they don't make any more. If you can help us find one on Craigslist - let us know. We have 3 of these, and we need 6 for the production run. These are our industry standard - until we build our own welders, of course.

True Fans Invitation

Dear True Fans and Supporters,

I am glad to send a few words once again - it's been many months since I spoke to you. Major growing pains this year - and finally, I feel we are stabilizing. I have a special place in my heart for all of you - as the people who truly got this project off the ground. Now we're at the tipping point of viral replication - and my hopes for 2013 are high. See the latest plan + 5 minute video -

http://opensourceecology.org/wiki/Shuttleworth_Fellowship_2013_Submission

Plus – we have just become finalists in the Focus Forward Film Competition with our 3 minute film – Build Yourself:

http://www.focusforwardfilms.com/#finalists

We are pleased to announce the OSE Christmas Gift to the World for 2012

http://opensourceecology.org/wiki/Christmas_Gift_to_the_World

Our gift is - for December 18, 2012 - to build our open source, automatic Brick Press - The Liberator - in a single day of production. We've come a long way since the first build in 2008. The gift means – that with the full documentation that we are providing, anyone in the world can replicate this readily – and in as little as one day with a CNC Torch Table. We look forward to hundreds of replications of the Brick Press next year – and people building high quality housing at low cost.

And you are invited to our 1-day build. We have 10 people participating on site so far, and our max is 16 participants. You can get involved in other ways, too. Modeling, cutting, documenting, remote video editing, tooling upgrades, CAD, CAM, and other topics - you can help us. See the Radical Collaboration section in the last link above.

I look forward to it - let's do it together.

Thanks,

Marcin

Production Crew

- Catarina Mota - Special Guest, Open Source Hardware Summit, Co-chair

- Rob Kirk - Special Guest, Digital Ranch, Film Director

- Marcin Jakubowski - Production Run Director

- Tristan Copley Smith - Videographer

- Parker Bonnell

- Kavitha Swaminathan

- Aaron Makaruk

- Jacob Dalton

- Ilya Tabakh - guest True Fan, Kansas City

- Fred Eisele