Slide 17

This page was tagged as a candidate for deletion. If this page does not meet our criteria for deletion, please remove this notice.

(Explanation: contents moved to Slide 1)

Slide 1 - Slide 2 - Slide 3 - Slide 4 - Slide 5 - Slide 6 - Slide 7 - Slide 8 - Slide 9 - Slide 10 - Slide 11 - Slide 12 - Slide 13 - Slide 14 - Slide 15 - Slide 16 - Slide 17 - Slide 18 - Slide 19 - Slide 20 - Slide 21 - Slide 22 - Slide 23 - Slide 24 - Slide 25 - Slide 26 - Slide 27 - Slide 28 - Slide 29 - Slide 30 - Slide 31 - Slide 32 - Slide 33

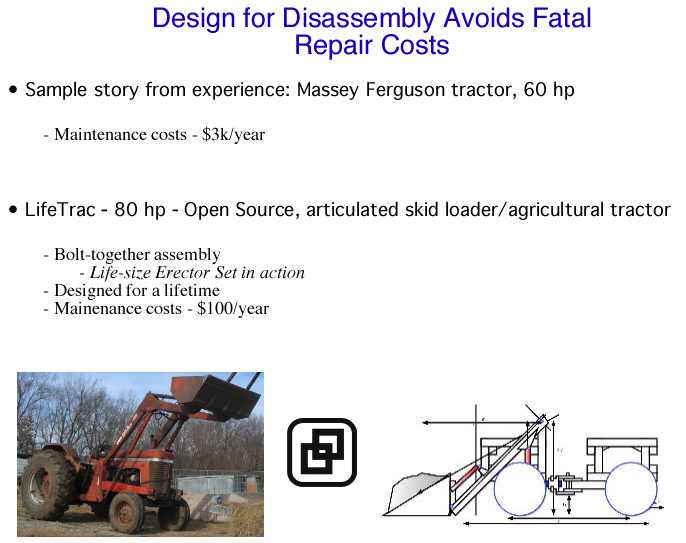

We have a good example from Factor e Farm that shows why design for disassembly is desirable. Our tractor broke. It takes 8 hours just to split the tractor in the middle to find out what is wrong. That job cost us $2k to fix. Soon after, the engine exploded. It may or may not be an easy fix, but it will also cost considerable labor to get into the engine to see what’s wrong. We decided to let the tractor lie dead in the woods – we can’t keep up with what turned out to be $3000/year overall costs of the tractor.

We decided to build a tractor designed for disassembly, from 4x4 steel tubing that bolts together at the corners. This is a true life-size Erector Set in action. We designed it to be taken apart, entirely, within about an hour. It is a multipurpose agricultural/construction tractor, with maintenance costs designed to be $100/year.